- Keeping it clean since 1934!

- (440) 259-2500

- [email protected]

Industrial Wash Systems for Reusable Packaging: A Smarter, Cleaner Solution

April 29, 2025

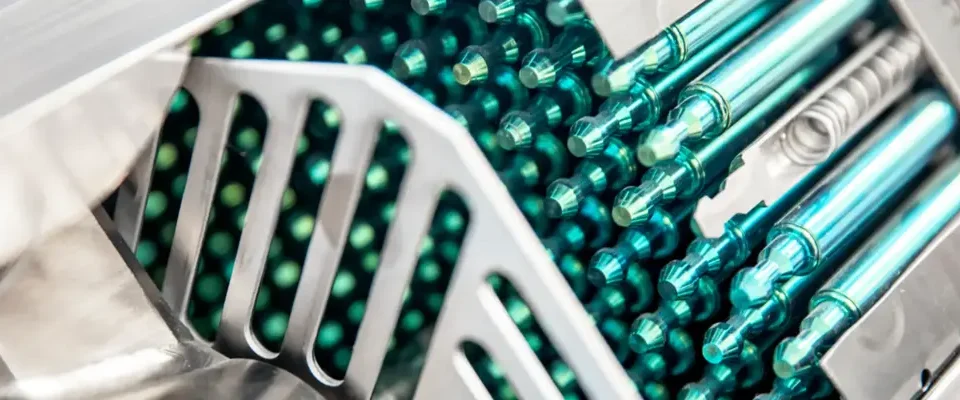

How Niagara Systems Built a Custom Washer for Nuclear Fuel Rods

June 25, 2025

From Bottleneck to Business Model: How Niagara Systems Engineered an Automated Pallet Washer for High-Volume Logistics

Pallets move the modern supply chain, but managing them at scale can quickly become a drain on resources if not engineered for efficiency. A leading logistics and additive operations company recognized this challenge firsthand as it sought to expand services and improve material handling efficiency. Instead of outsourcing or scaling labor, the company identified an opportunity: create a revenue-generating process by investing in a fully automated pallet washing system.

This case study explores how we delivered a purpose-built automated pallet washer that transformed a maintenance task into a strategic asset.

The Challenge: Turning a Cost Center into a Revenue Stream

The customer—a major logistics and additive operations company—was facing a familiar issue at an entirely different scale. With pallets moving continuously through its facilities, the cleaning and inspection process had become a bottleneck. Manual washing was labor-intensive, inconsistent, and incapable of supporting the company’s growth strategy.

But rather than view pallet cleaning as a necessary overhead, the customer saw a strategic opportunity: transform it into a value-added service. The goal was to implement an automated pallet washing solution that could process large volumes quickly, uphold cleanliness and structural integrity standards, and operate as a self-contained business unit within the logistics network.

The system would need to:

- Handle high-throughput volumes exceeding 500 pallets per hour.

- Minimize labor requirements through full automation.

- Ensure consistent quality control for reusable pallets.

- Seamlessly integrate with existing logistics workflows and infrastructure.

The challenge wasn’t just technical—it was operational. Success required a solution that combined smart automation, durable materials, and a deep understanding of logistics efficiency. That’s exactly what we set out to deliver.

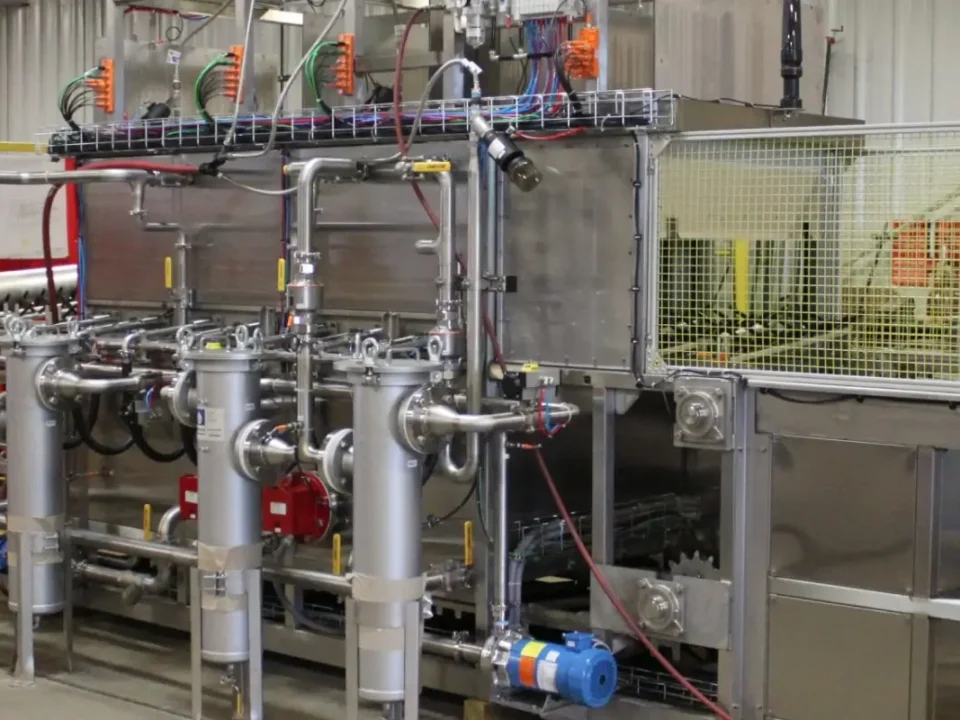

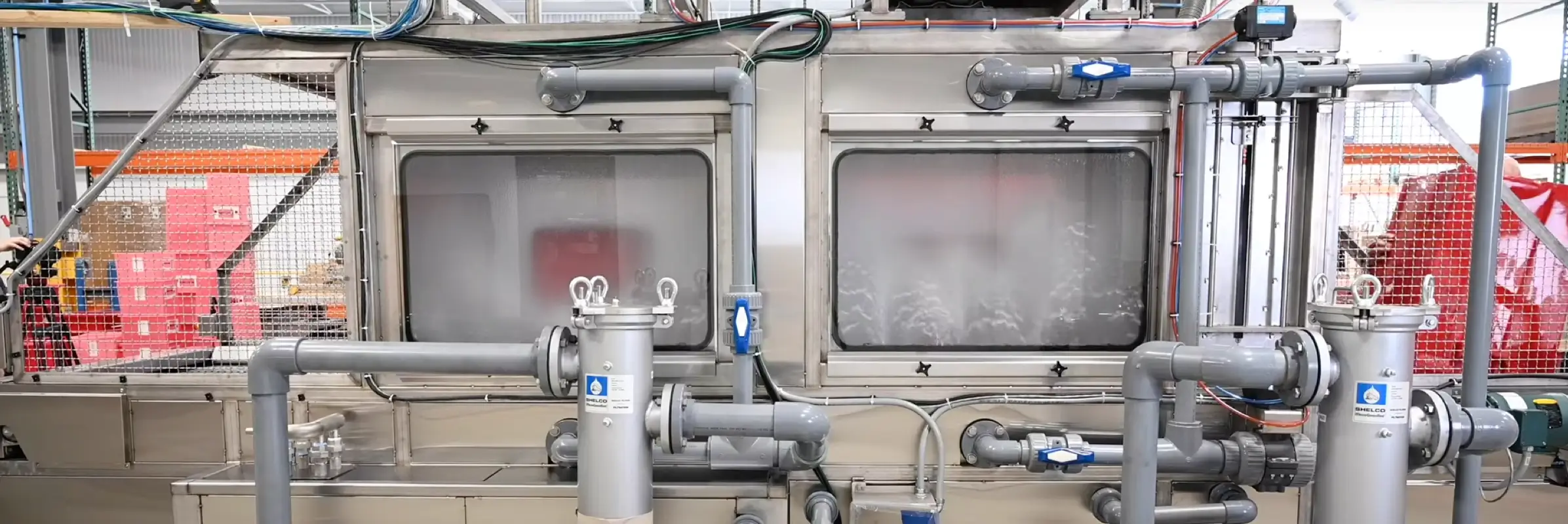

The Solution: A Fully Integrated Automated Pallet Washer System

Niagara Systems approached the project with one objective: engineer a high-performance automated pallet washer that could meet the customer’s throughput demands while embedding into their logistics ecosystem. Rather than retrofit existing equipment, the solution was built from the ground up to operate as an autonomous system capable of continuous, high-speed processing.

The final deployment consisted of three parallel, fully automated lines, each engineered for peak reliability and modular scalability. Key system features included:

- Custom Material Handling: A tailored conveyor and guidance system ensured smooth, uninterrupted transport of pallets from start to finish—no manual repositioning, no missed timing.

- High-Speed De-Stacking and Re-Stacking: To optimize throughput, the system incorporated rapid de-stacking and re-stacking units, allowing full pallet stacks to be processed with minimal downtime between cycles.

- Inline Inspection and Rejection: Advanced sensors were embedded to assess both cleanliness and structural integrity. Any pallet failing inspection was automatically rerouted for rejection or rework, ensuring only compliant pallets advanced for reuse.

- Robotic Loading and Unloading: Industrial robotic arms handled pallet movement at the system’s infeed and outfeed, eliminating the need for forklift staging or human touchpoints—critical for labor reduction and operator safety.

- Custom Washing Technology: Each line featured a high-powered wash stage tuned to meet the cleanliness standards necessary for redistribution. Water pressure, cycle duration, and chemical application were all controlled to deliver repeatable results without damaging the pallet surfaces.

The Results: Throughput, Quality, and Profitability

With Niagara Systems’ automated pallet washer fully operational, the impact on the customer’s logistics infrastructure was immediate and measurable. What began as a maintenance requirement quickly evolved into a streamlined, revenue-generating operation.

Unmatched Throughput

Each line consistently processes over 500 pallets per hour, turning what was once a time-consuming task into a rapid, continuous-flow operation. This level of throughput significantly reduced backlogs and freed up space within the facility for higher-value activities.

Labor Reduction Without Compromise

The system’s robotic loading, unloading, and material handling functions dramatically reduced manual labor. The company no longer needed dedicated crews for pallet washing, which reduced overhead while improving consistency and safety.

Reliable Quality Control

With integrated inspection and rejection systems, the solution guarantees that only structurally sound, sanitized pallets return to circulation. This not only protects downstream operations from contamination or equipment damage but also reinforces brand trust in the quality of redistributed assets.

Scalable Business Model

What began as an operational fix has become a competitive advantage. The company now markets automatic pallet washing as a service, offering clean, reusable pallets to partners and clients across the supply chain. With proven success across three automated lines, expansion into new facilities is already under evaluation.

What made the system exceptional wasn’t just its speed—it was its ability to self-regulate, adapt to varying pallet conditions, and maintain consistent output without operator intervention.

Why Automatic Pallet Washing Is the Future of Sustainable Logistics

As logistics networks scale, so does the need for smarter, cleaner, and more cost-effective material handling practices. Pallets—essential but often overlooked—represent both a logistical challenge and an opportunity for sustainable innovation. Automated pallet washer systems are increasingly recognized as a critical tool in closing the loop between operational efficiency and environmental responsibility.

Driving Circularity Through Reuse

Rather than discarding or outsourcing cleaning, automated systems enable companies to extend the lifecycle of each pallet, reducing waste and supporting internal reuse programs. This not only saves money but also contributes to ESG goals and sustainability benchmarks increasingly demanded by corporate stakeholders.

Mitigating Labor and Safety Challenges

Warehouses are under pressure from rising labor costs, staffing shortages, and increasingly strict safety standards. Automating repetitive, high-volume tasks like pallet cleaning reduces the burden on human operators while improving process safety and ergonomics.

Ensuring Compliance and Consistency

In industries where cleanliness is a requirement, such as food, pharmaceuticals, and high-volume distribution, manual pallet cleaning introduces risk. An automated pallet washer eliminates variability and enables full control over wash parameters, ensuring repeatable results that meet regulatory or partner standards.

Built to Scale with Operational Needs

Custom-engineered systems, like those developed by Niagara Systems, are designed to grow with the business. Whether you need to process a few hundred pallets a day or several thousand, automation provides the flexibility and throughput required to meet evolving logistics demands, without compromising quality or uptime.

Learn More About Our Custom Solutions

At Niagara Systems, we specialize in solving industrial challenges where speed, precision, and reliability matter most. For this logistics leader, the challenge wasn’t just to clean pallets—it was to create a fully automated system that could turn an operational burden into a scalable business asset.

By engineering a custom automated pallet washer with intelligent material handling, robotics, and high-throughput capabilities, we helped our client unlock a new revenue stream, reduce labor dependency, and elevate their logistics infrastructure. And we’re ready to do the same for you.

Automate Smarter. Scale Faster. Get a Custom Solution for Your Industry at Niagara

Whether you’re processing hundreds or thousands of pallets per hour, our team can design a solution tailored to your workflow, facility layout, and cleanliness standards. Let’s build the system that moves your operation forward. Request a custom quote today and see what’s possible with Niagara Systems.

Frequently Asked Questions About Automated Pallet Washers

If you’re exploring ways to improve pallet management through automation, you’re not alone. Below are answers to common questions about automated pallet washers.

What is automatic pallet washing?

Automatic pallet washing is a fully mechanized process that cleans and sanitizes pallets using conveyor systems, wash stages, and inspection technology, without manual handling. These systems are often integrated into logistics or production facilities to support high-volume throughput and reuse.

How does an automated pallet washer handle damaged or non-compliant pallets?

Advanced systems include inline inspection and rejection capabilities. These features identify pallets that fail structural or cleanliness checks and automatically divert them from the main process for rework or disposal.

What are the long-term benefits of investing in an automated pallet washer?

Automated pallet washers reduce labor costs, minimize process variability, support reuse strategies, and improve hygiene and compliance. They also unlock new revenue opportunities by enabling companies to offer clean pallet services to partners and customers.