Efficient Cleaning for a Sustainable Supply Chain

Reusable packaging is driving the shift toward more efficient, cost-effective, and sustainable logistics. But without the right cleaning system, operations can face serious bottlenecks—contaminated bins, pallets, and containers slow down workflows and fail compliance checks. That’s where Niagara Systems can help.

We custom-design and build reusable packaging washers that eliminate contamination, optimize turnaround times, and extend the lifespan of reusable transport assets. Whether you need a high-capacity industrial pallet or bin washer, an IBC washer with precise drying capabilities, or a bulk container washer integrated into an automated system, we build to spec.

Tell us your requirements today, and we’ll build the solution to match.

Request a Quote »How We Improve Your Operations

Every industry using reusable packaging has unique demands; thankfully, our reusable packaging washers will meet them. Whether you’re handling food-grade bins, pharmaceutical IBCs, or high-use industrial pallets, we’ll custom-build a washer with the right features to keep operations running smoothly.

Precision Cleaning & Contamination Control

Contaminants don’t belong in your supply chain. Our washers use high-performance cleaning systems to remove tough residues, powders, and grease, ensuring every package meets strict cleanliness standards.

- Targeted High-Pressure Spray Systems: Eliminate debris and buildup from every surface, including deep grooves and internal channels.

- Sanitization & Disinfection Options: Integrated chemical injection ensures compliance with food safety, pharmaceutical, and industrial-grade cleaning requirements.

Automated Handling & Workflow Integration

Manual handling slows down throughput and increases labor costs. Our systems easily integrate into automated operations, keeping your reusable packaging moving efficiently.

- Conveyor-Integrated Systems: Automate the wash cycle by moving packaging through each phase with minimal manual intervention.

- Stacking & Destacking Capabilities: Reduce handling time and streamline logistics by automating the movement of washed packaging.

- RFID & Barcode Tracking Integration: Link wash cycles to packaging data for traceability, compliance, and quality control.

Optimized Drying for Immediate Reuse

Wet packaging slows down operations and creates contamination risks. Our drying solutions ensure that pallets, bins, and containers are clean, dry, and ready for immediate use.

- High-Velocity Forced-Air Drying: Eliminates moisture quickly, preventing microbial growth and reducing wait times.

- Custom Drainage & Tilt Features: Designed for irregularly shaped packaging, these features optimize water runoff and improve drying efficiency.

Built for Efficiency, Durability & Sustainability

Downtime and inefficiency cut into your bottom line. Our washers are built tough, energy-efficient, and scalable to match your operation’s needs.

- Stainless Steel Construction: Corrosion-resistant and designed for continuous, heavy-duty operation.

- Water & Energy Efficiency: Recirculating filtration systems reduce water waste without compromising cleaning performance.

- Modular Design for Expansion: Systems can scale up to accommodate increased throughput as your operation grows.

Tell us what you need, and we’ll design a reusable packaging washer that works.

Configured for Your Operation, Built to Your Specs

No two industries handle reusable packaging the same way. That’s why Niagara Systems doesn’t lock you into a standard design. Our reusable packaging washers can be built in any configuration—from standalone batch systems to fully integrated, high-capacity conveyor lines. Whether you need a compact footprint for limited space, a multi-stage cleaning process for strict contamination control, or automated handling for high throughput, we design solutions that fit your workflow.

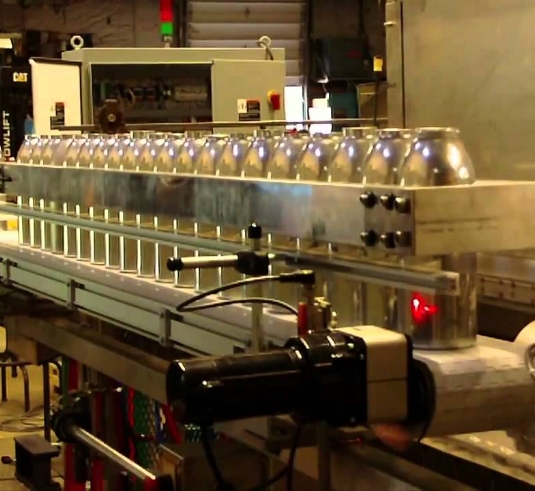

One of our most versatile and high-performance options is the Series 200 Tunnel-Style Washer—a perfect choice for continuous, high-volume cleaning of pallets, bins, IBCs, and bulk containers.

The Series 200: Industrial Tunnel Washing, Customized to Spec

The Series 200 Tunnel-Style Washer is great for heavy-use, high-throughput operations; especially those that need consistent, automated cleaning. Whether you’re in food processing, pharmaceuticals, logistics, or industrial manufacturing, this system delivers fast, repeatable results with minimal manual handling.

Key Performance Features:

- Modular Conveyor System: Move reusable packaging through wash, rinse, and drying stages without bottlenecks.

- High-Pressure Spray Manifolds: Targeted cleaning removes dirt, grease, powders, and contaminants from all surfaces, including complex internal structures.

- Automated Detergent & Sanitization Control: Configurable for food safety, pharmaceutical compliance, or industrial-grade cleaning.

- Water & Energy Efficiency: Advanced recirculating filtration minimizes resource waste while maintaining optimal cleaning power.

With the Series 200, you get a scalable, high-capacity washing system that meets the toughest industry demands while reducing labor, water usage, and contamination risks. Tell us your specifications, and we’ll configure the perfect solution.

Let’s Build the Right Solution for Your Operation

A one-size-fits-all reusable packaging washer won’t cut it when your business depends on clean, compliant, and ready-to-use reusable packaging. Niagara Systems builds custom-engineered washing solutions that fit into your workflow—whether you need a high-capacity tunnel system, a fully automated conveyor line, or a compact batch washer.

Tell us your cleaning challenges, industry requirements, and operational goals, and we’ll design a system that keeps your packaging moving. Get in touch today to start the conversation.

Frequently Asked Questions: Reusable Packaging Washers

If you’d like to learn more about our reusable packaging washers, please check out the answers to our most frequently asked questions down below!

What types of contaminants can Niagara Systems’ reusable packaging washers remove?

Our washers are designed to handle a wide range of contaminants, including food residues, industrial oils, grease, powders, adhesives, and chemical residues. Depending on industry requirements, we can integrate high-pressure spray systems, chemical sanitization, and filtration technologies to meet strict cleanliness standards.

How energy- and water-efficient are Niagara Systems’ reusable packaging washers?

Our washers utilize recirculating water filtration, energy-efficient drying systems, and optimized spray pressure to reduce waste while maintaining high-performance cleaning. We engineer our systems to meet sustainability goals without sacrificing cleaning power.

Can a reusable packaging washer be relocated or modified after installation?

Most of our washers are modular, meaning they can be expanded, reconfigured, or relocated as your operation grows. We design with future scalability in mind, allowing for additional wash zones, drying stations, or conveyor extensions as needed.