- Keeping it clean since 1934!

- (440) 259-2500

- [email protected]

From Bottleneck to Business Model: How Niagara Systems Engineered an Automated Pallet Washer for High-Volume Logistics

June 24, 2025

Industrial Cleaning Solvent vs. Aqueous Cleaning Solution: What’s Best for Your Application?

January 5, 2026

How Niagara Systems Built a Custom Washer for Nuclear Fuel Rods

When working with nuclear energy, there’s no room for error. The manufacturing and processing of nuclear fuel components demand absolute precision, along with materials and systems that can withstand extreme chemical and environmental stressors. As global energy demands grow and safety regulations tighten, the need for highly specialized automation systems continues to rise.

That’s where Niagara Systems excels. When a leading nuclear reactor supplier needed a solution for processing the interiors of fuel rods—a process requiring surgical accuracy and chemical resilience—they turned to us for a custom-engineered answer. What followed was a collaborative effort that fused mechanical ingenuity with complex parts washing automation, resulting in a critical system now central to one of the most sensitive manufacturing processes in the energy sector. Let’s talk about it.

The Challenge: Processing the Inside of a Nuclear Fuel Rod

Fuel rods are a cornerstone of nuclear reactors, so the stakes for manufacturing them couldn’t be higher. Even the slightest variation in their internal structure can compromise efficiency, safety, or regulatory compliance. For one prominent nuclear reactor supplier, internal machining of fuel rods had become a bottleneck. They needed a fully automated solution that could deliver unwavering precision while withstanding the highly corrosive chemicals used during processing.

This wasn’t a typical washing or machining application. The system had to accomplish three critical goals:

- Ensure Even Internal Treatment: The inside of each fuel rod required uniform flushing to maintain structural consistency and support nuclear performance standards.

- Operate with Micron-Level Precision: Internal diameters had to fall within extremely tight tolerances, demanding accurate, repeatable measurement tools integrated into the process.

- Survive a Harsh Chemical Environment: The use of strong acids and aggressive cleaning agents ruled out many conventional materials and significantly narrowed the design window.

In short, traditional industrial automated washers couldn’t handle the job. This nuclear supplier needed a custom-built system to manage extreme accuracy and chemical exposure without compromising throughput or long-term reliability—a tall order by any standard, but well within Niagara’s capabilities.

The Solution: Precision, Anti-Corrosion, and Automation

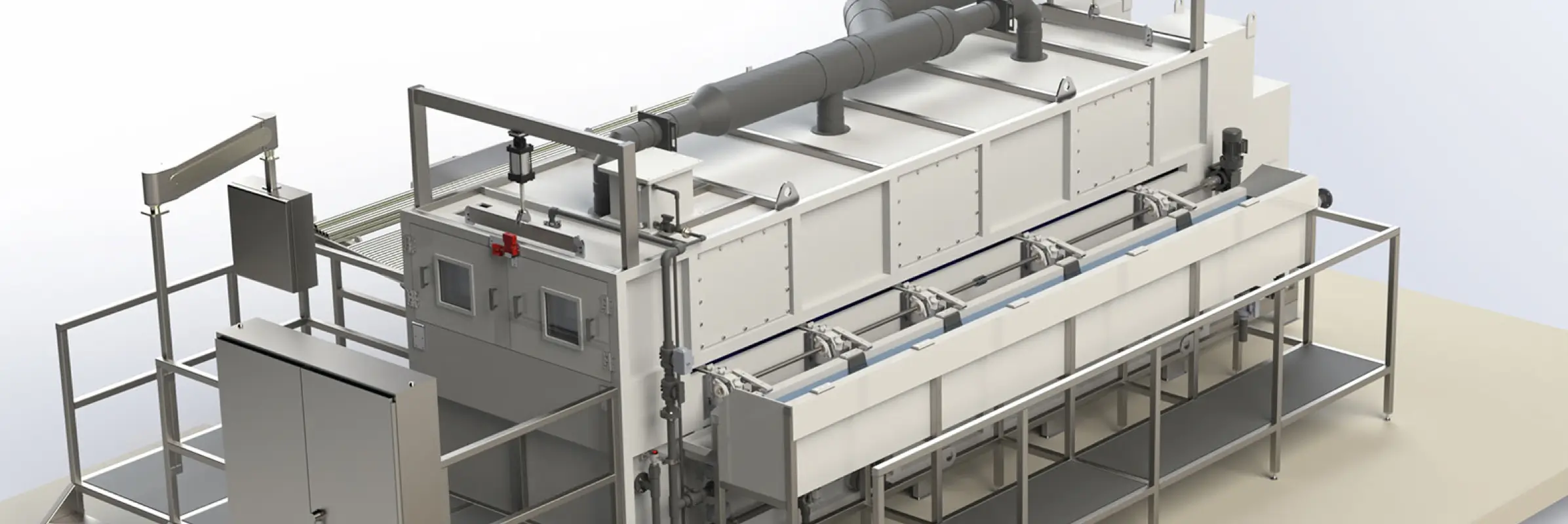

Our team approached this challenge knowing we weren’t looking to retrofit or modify any of our existing washers—we needed a fully custom-engineered system designed from the ground up to meet the unique demands of nuclear fuel rod processing.

Precision at the Core: Internal Flushing + Ultrasonic Measurement

To achieve even internal treatment, our engineers developed a flushing system that ensured uniform chemical exposure throughout the internal cavity of each rod. This addressed the customer’s demand for consistency and minimized the risk of defects.

To meet strict tolerance requirements, ultrasonic measurement technology was integrated into the process. This advanced system continuously monitored internal diameters (ID) to micron-level accuracy, allowing real-time quality control and immediate detection of any out-of-spec dimensions.

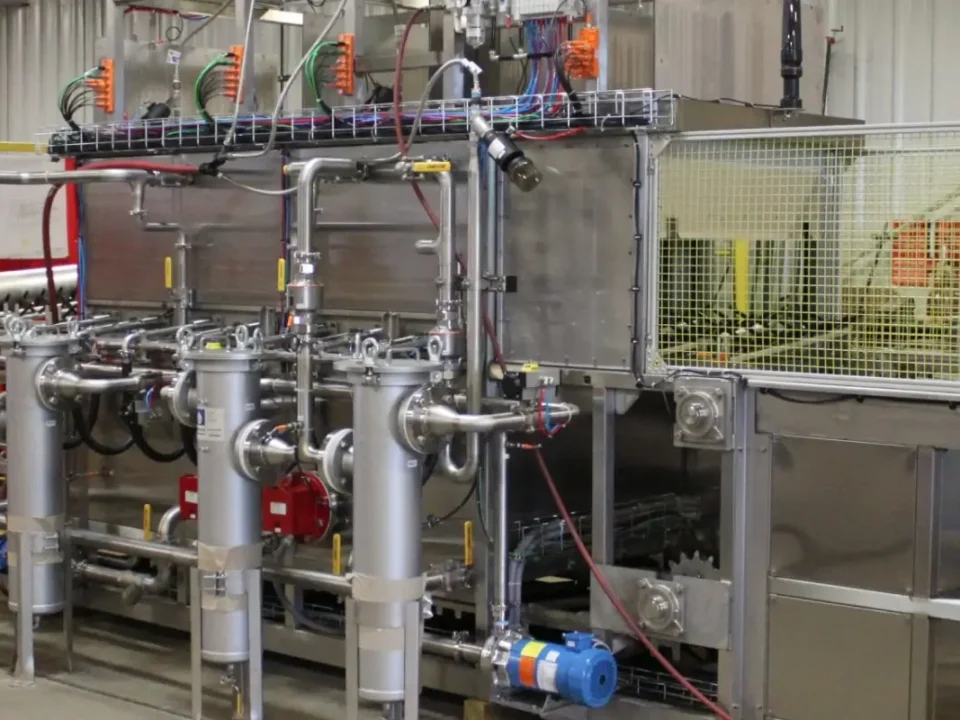

Built for Harsh Chemistry: 316SS + Polypropylene Protection

Understanding the corrosive nature of the cleaning agents used, we selected 316 stainless steel (316SS) as the structural base—an alloy renowned for its superior corrosion resistance in aggressive environments. But we couldn’t stop there. To further insulate the system from chemical attack, the entire framework was encased in polypropylene, a chemically inert material that provides an added layer of durability and protection.

Integrated Expertise Across Disciplines

This solution wasn’t the product of a single specialty. It was the result of collaboration between our mechanical designers, controls engineers, and automation specialists. Because of this, we created a breakthrough in custom industrial washing machines: a fully automated, corrosion-resistant line with uncompromising accuracy, even in the most unforgiving conditions.

The Results: Long-Term Performance in a High-Stakes Environment

Once installed, our custom automation line quickly became a vital component in the customer’s nuclear fuel rod manufacturing process. Every rod produced now moves through this tailored system, ensuring that each one meets the exacting standards required for use in a nuclear reactor.

Uncompromising Quality Control

Thanks to the integration of ultrasonic measurement and uniform internal flushing, the system maintains consistent quality across every cycle. Tolerances are no longer a variable; they’re a guarantee. This level of control is essential in the nuclear industry, where even microscopic imperfections can lead to costly rework or regulatory non-compliance.

Reliable Operation in Harsh Conditions

Where conventional industrial automated washers might break down or degrade under prolonged exposure to corrosive chemicals, Niagara’s system thrives. The combination of 316 stainless steel and polypropylene cladding delivers exceptional resistance to corrosion and chemical wear, reducing maintenance needs and increasing operational uptime.

Efficiency Through Intelligent Automation

Beyond durability, the custom line enhances production throughput. By automating processes that were previously manual or inconsistent, Niagara’s solution reduces processing time, eliminates variability, and supports scalable fuel rod production, all while maintaining rigorous safety and quality standards.

This isn’t just a case of solving a problem; it’s an example of strategic innovation. The supplier now benefits from a streamlined, dependable process that empowers them to meet current demand and scale confidently for the future.

Why Custom Industrial Washing Machines Matter in Nuclear Applications

When it comes to nuclear energy, the margin for error is razor-thin, and the consequences of failure are significant. That’s why off-the-shelf equipment rarely makes the cut. Custom solutions like ours aren’t a luxury in nuclear applications; they’re the only way forward.

By combining custom mechanical design with advanced parts washing automation, we helped this customer turn a complex, error-prone process into a predictable and scalable operation. Automation not only improves consistency but also enables real-time monitoring, data collection, and traceability—all critical features in highly regulated sectors like nuclear, aerospace, and medical manufacturing.

This case underscores the value of working with a partner who understands the nuance of both engineering and industry. Niagara Systems brings deep experience in designing industrial automated washers to solve the toughest challenges, whether handling aggressive chemicals, achieving sub-millimeter accuracy, or integrating into an existing production ecosystem.

Learn More About Our Custom Solutions

When a leading nuclear reactor supplier came to us with an urgent challenge, we didn’t offer a generic fix. We engineered a custom solution built to withstand the harshest conditions, deliver ultra-tight tolerances, and support long-term reliability in a highly regulated environment.

This project highlights what we do best: designing custom industrial washing machines and industrial automated washers that solve complex problems through thoughtful engineering and advanced parts washing automation. From corrosive chemical exposure to critical dimensional accuracy, we develop solutions that push the limits of what’s possible.

Get a Custom Automation Solution Engineered for Your Industry

If your application requires a higher standard of automation—whether you’re in the nuclear sector, aerospace, defense, or beyond—we’re ready to help. Let’s build something extraordinary together. Request a custom quote today and discover what Niagara Systems can do for your operation.

Frequently Asked Questions About Parts Washing Automation

If you’re considering upgrading or customizing your cleaning process, you likely have questions about what parts washing automation can offer. Below, we answer some of the most common questions from engineers, operations managers, and plant leaders exploring automated solutions.

What is parts washing automation?

Parts washing automation refers to the use of automated systems to clean, flush, or treat components, often in manufacturing or industrial settings, without manual intervention. These systems are designed for consistency, efficiency, and repeatability, especially when dealing with complex geometries or stringent cleanliness requirements.

How do I know if I need a custom solution versus a standard parts washer?

If your process involves harsh chemicals, exacting tolerances, complex geometries, or strict regulatory requirements, a standard washer may not be sufficient. A custom-engineered system can be tailored to your application, ensuring performance, longevity, and compliance.

What materials can automated washers handle safely?

Modern systems can be engineered to clean a wide variety of materials, including stainless steel, aluminum, titanium, composites, and even some plastics. Material compatibility is a key consideration when designing custom industrial washing machines.