Industrial Ultrasonic Cleaning Systems

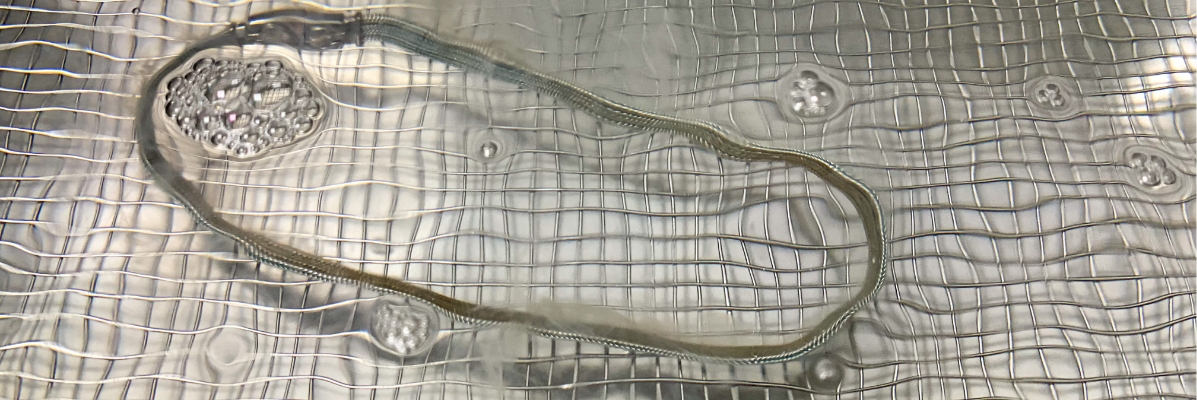

Ultrasonic cleaning uses high-frequency sound waves to remove contaminants from submerged parts with exceptional precision. The process works through cavitation; when ultrasonic waves pass through a liquid, they create millions of microscopic bubbles that collapse on contact with surfaces. This implosion lifts away oils, greases, and particulates, even from blind holes, tight crevices, and delicate finishes.

Unlike traditional cleaning methods that rely on pressure or abrasion, ultrasonic cleaning systems clean thoroughly without damaging sensitive components. It’s a powerful solution for industries that demand absolute cleanliness in every cycle. Need a deeper clean? Let’s talk about how an ultrasonic cleaner can work for your industrial parts.

Why Choose Ultrasonic Over Traditional Cleaning?

When cleanliness standards are high, ultrasonic technology often outperforms manual washing, spray cabinets, or solvent-based systems. It’s not just a different approach. It’s a smarter one, especially for complex parts or delicate materials.

The Advantages of Ultrasonic Cleaning

Ultrasonic cleaning systems offer unique benefits that go beyond surface-level results. They provide processes with consistency, reduce labor, and support sustainability, all while reaching places other methods can’t.

- Deep, Precision Cleaning: Reaches blind holes, internal passages, and tight geometries that spray nozzles can’t access.

- Non-Damaging to Sensitive Parts: Ideal for polished metals, coated components, medical tools, and electronics.

- Repeatable, High-Quality Results: Perfect for industries that require validated, tightly controlled cleaning outcomes.

- Labor-Saving & Scalable: Reduces manual labor, rework, and operator variability. Automation-friendly by design.

- Eco-Conscious: Uses less water and fewer harsh chemicals than pressure-wash systems; good for your process and the planet.

By combining physics, chemistry, and smart engineering, ultrasonic cleaning systems offer a powerful, reliable solution for today’s industrial cleaning challenges.

Things to Consider When Searching for an Industrial Ultrasonic Cleaning Machine

While ultrasonic technology provides impressive cleaning performance, it’s important to weigh your application needs, budget, and part size when choosing a solution. For some operations, custom sizing or adjusted expectations may be part of the equation.

- Upfront Investment: An industrial ultrasonic cleaning machine may have a higher initial cost, but it offers long-term ROI through efficiency and consistency.

- Cycle Time Variations: Ultrasonic cleaning can take slightly longer than spray systems for certain applications, but it often eliminates the need for secondary cleaning.

- Tank Size Constraints: Larger parts may require custom tank dimensions or multi-stage designs to accommodate size and weight.

Applications & Industries Served

Ultrasonic cleaning systems are trusted in industries where surface cleanliness isn’t optional. Whether you’re removing machining oils from intricate metal parts or sterilizing delicate surgical instruments, ultrasonic technology ensures deep, repeatable results across a wide range of use cases.

From aerospace hangars to pharmaceutical cleanrooms, here are just a few of the sectors where an ultrasonic cleaner industrial solution makes a real impact.

Aerospace & Defense

Ultrasonic parts washers work by using high-frequency sound waves to agitate a cleaning solution. Generally, ultrasonic cleaning uses a bath or tank to clean your industrial parts. The agitation caused by sound waves causes cavitation, where microscopic bubbles implode or collapse. This cavitation creates highly energetic jets of fluid that remove contaminants from the surface of your industrial parts.

Can an Ultrasonic Washer Damage Parts?

Cleans fuel system components, turbine blades, hydraulic valves, and instrumentation with high precision.

Medical & Surgical Devices

Removes bio-burden and residue from surgical tools, dental equipment, and orthopedic implants without damaging critical surfaces.

Electronics & Semiconductor

Ideal for printed circuit boards, precision connectors, wafers, and other components sensitive to static or abrasion.

Metalworking & Machining

Degreases machined parts, tooling, molds, and dies—removing oils, chips, and particulate matter before finishing or assembly.

Pharmaceutical & Laboratory

Thoroughly cleans lab glassware, stainless parts, and small-scale production components to meet regulatory standards.

Injection Molding & Plastics

Removes buildup from mold cavities, nozzles, and ejector pins to maintain consistent part quality.

Whether you need a standalone industrial ultrasonic cleaning machine or a fully integrated system tailored to your workflow, Niagara Systems builds solutions that meet your specs and your industry’s standards.

Industrial Ultrasonic Cleaning System Types & Customization

Niagara’s SC-series ultrasonic washers offer scalable cleaning power for everything from delicate components to heavily contaminated parts.

Explore the SC-Series Lineup

While originally engineered for automotive remanufacturing, these industrial ultrasonic cleaning systems are versatile enough for any operation that demands consistent, high-performance results.

SC‑6.6 to SC‑33

These compact, space-efficient units are ideal for smaller parts, lighter throughput, or work cells where floor space is limited. Despite their small footprint, they provide full ultrasonic power and precision cleaning in a standalone package.

SC‑66 to SC‑132

A mid-range solution for operations that require more volume or larger baskets. These models are a strong fit for contract manufacturing, mid-size production lines, or facilities with a mix of part sizes and soil levels.

SC‑264 to SC‑2000

Designed for large-scale, industrial applications. These heavy-duty systems accommodate larger parts, dense loads, and continuous use, making them ideal for aerospace, machining, energy, and remanufacturing environments. Optional automation, filtration, and recirculation systems are available for enhanced throughput and efficiency.

Built to Your Specs

Every SC-series ultrasonic cleaner can be tailored to match your process. From tank sizing and frequency tuning to programmable cycle controls and closed-loop fluid handling, Niagara designs with your application—and future growth—in mind.

Need help selecting the right ultrasonic cleaning system? Our team can help configure a solution that meets your part size, soil type, and throughput goals.

Frequently Asked Questions: Ultrasonic Cleaning Systems

Have questions about ultrasonic cleaning systems? Here are some of the most common inquiries we hear from manufacturers and facility teams exploring ultrasonic technology for the first time.

What materials can be cleaned with ultrasonic cleaning systems?

Ultrasonic cleaning systems are safe and effective for metals, ceramics, glass, hard plastics, and certain composites. They’re commonly used to clean stainless steel, aluminum, titanium, brass, and precision-machined parts without damaging the surface.

Do ultrasonic cleaners require special cleaning solutions?

Yes, most industrial ultrasonic cleaning machines use a water-based solution with a mild detergent or chemistry specific to the contamination type. Using the correct solution improves cleaning performance and helps protect sensitive parts from corrosion or residue.

Can ultrasonic cleaning systems be automated?

Yes. Many facilities integrate ultrasonic cleaner industrial units into automated workflows, including robotic loading, conveyor-fed systems, or multi-stage cleaning lines. Niagara Systems offers automation-ready designs tailored to your throughput and handling requirements.

Bring Industrial-Grade Cleanliness to Your Process with a Custom Ultrasonic Solution

With over 80 years of experience designing and building industrial cleaning equipment, Niagara Systems is more than a manufacturer; we’re a problem-solving partner. Every ultrasonic cleaning system we produce reflects decades of engineering expertise, built in the USA and backed by a team that understands the pressure of production schedules and quality audits.

As part of South Shore Controls, we offer full integration capabilities, from standalone ultrasonic tanks to fully automated, multi-stage wash systems tailored to your workflow. Ready to see how our ultrasonic technology fits your facility? Let’s get the conversation started.