- Keeping it clean since 1934!

- (440) 259-2500

- [email protected]

Niagara Systems Expanding Manufacturing Facility

October 11, 2023

From Bottleneck to Business Model: How Niagara Systems Engineered an Automated Pallet Washer for High-Volume Logistics

June 24, 2025

Industrial Wash Systems for Reusable Packaging: A Smarter, Cleaner Solution

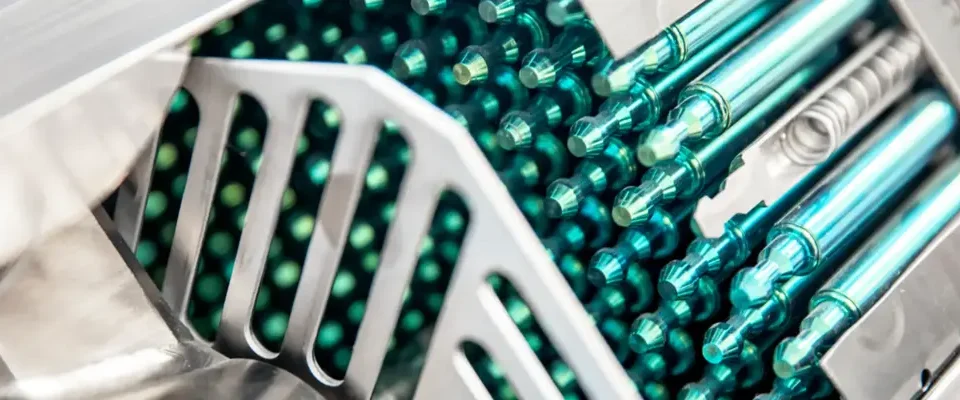

In modern manufacturing and distribution environments, reusable packaging has moved from a sustainability initiative to an operational standard. Reusable pallets, totes, bins, and IBCs all offer a smarter way to minimize waste, reduce material costs, and align with broader environmental goals. But with that shift comes a critical challenge: maintaining the cleanliness and integrity of every container in circulation.

Residues, films, or cross-contamination can compromise product quality, halt production, and erode customer trust—especially in regulated or hygiene-sensitive industries. That’s why in this article, we’ll explore how to make sure your system is up to the task, and how Niagara Systems’ can offer a smarter, cleaner approach to washing and sanitizing reusable packaging.

Smarter Sanitation Matters in the Age of Reusable Packaging

As more manufacturers transition to reusable industrial packaging, the operational focus naturally shifts to maintaining its cleanliness between cycles. Totes, bins, pallets, and containers used repeatedly across environments become contamination risks if not properly sanitized. That risk doesn’t just apply to food and pharmaceutical sectors; even in automotive, aerospace, and general manufacturing, residual buildup can compromise product integrity and downstream equipment.

Increased scrutiny from regulatory bodies and quality assurance teams has made cleaning protocols a critical part of operational audits. And the more complex or high-touch the workflow, the greater the risk introduced by improper wash processes. That’s where engineered wash systems, validated against recognized sanitation standards, play a pivotal role in closing the loop between reuse and reliability.

How RPA-Compliant Washers Protect Your Operation

Unlike single-use containers, reusable packaging must withstand repeated exposure to contaminants while returning to service in a clean, validated condition. The Reusable Packaging Association (RPA)—a trade organization focused on advancing the performance and safety of reusable packaging systems—has established formal guidelines for the washing and sanitation of reusable containers. These protocols address the full cleaning lifecycle, including required water temperatures, chemical contact times, drying expectations, and microbial risk thresholds.

As a member of the RPA, Niagara Systems aligns directly with the organization’s published guidance on washing and sanitation for reusable industrial packaging. Being part of the RPA isn’t a footnote for us—it’s how we stay connected to the industry’s evolving needs. It ensures every system we build supports not just operational efficiency, but also the integrity of a company’s reusable packaging strategy from the inside out.

Inside the Series 200 Reusable Industrial Packaging Tunnel Washer

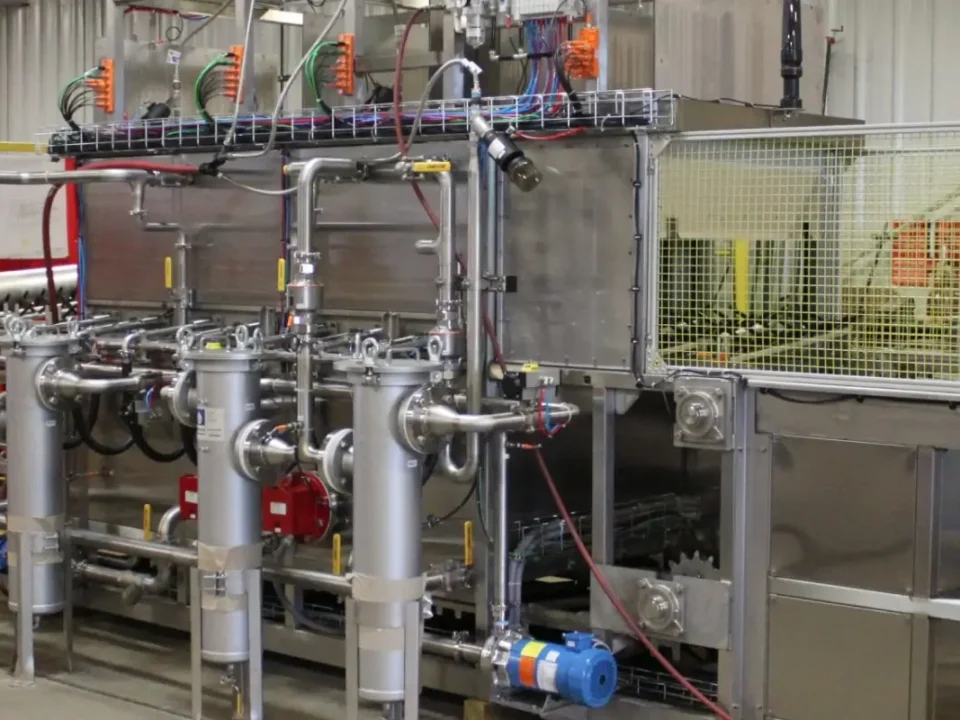

Reusable packaging doesn’t operate in controlled environments. It moves through production floors, warehouses, shipping docks, and storage areas—accumulating a wide range of residues from industrial oils to organic soils and particulate debris. To prepare these containers for reuse, wash systems must deliver consistent, high-contact cleaning across variable container geometries and levels of contamination. That’s precisely what our Series 200 tunnel washer is built to do.

We designed the Series 200 as a modular, in-line solution capable of sustaining performance in high-throughput industrial environments. It is particularly suited for operations that require validated sanitation results while minimizing manual handling and unnecessary system downtime.

Key Advantages for Reusable Industrial Packaging

Mechanically, the Series 200 leverages:

- Targeted Spray Coverage: Adjustable nozzles and pressure control allow operators to fine-tune spray zones for direct impact on problem areas, including deep-set crevices or heavily soiled container bottoms.

- Consistent Thermal Performance: Built-in temperature regulation and chemical injection maintain RPA-recommended cleaning conditions, ensuring sanitization is validated.

- Inline Drying Modules: For operations that require dry containers post-wash, the Series 200 offers configurable drying stages with directional airflow and heat integration to reduce recontamination risk.

- Low-Maintenance Design: Stainless steel construction, accessible access panels, and inline filtration keep maintenance cycles predictable and downtime minimal.

In facilities where sanitation compliance, throughput efficiency, and equipment reliability must coexist, the Series 200 provides an engineered platform that doesn’t require compromise. It’s not a one-size-fits-all solution—it’s a system that can be tailored to the physical and procedural demands of reusable industrial packaging workflows.

Customize Where It Counts: Reusable Packaging Washers Built to Spec

Reusable packaging isn’t standardized. Even within the same facility, you’ll often find multiple container sizes, materials, wall thicknesses, and structural designs—each with unique cleaning and drying requirements. Off-the-shelf wash systems rarely account for this variability, which leads to inconsistent results, overuse of resources, and operational inefficiencies.

That’s why Niagara Systems engineers the Series 200 not as a static product, but as a configurable platform. Belt widths, conveyor speeds, nozzle arrays, chemical dosing systems, filtration stages, and drying modules can all be tailored to the specific requirements of your packaging types and contamination challenges. Whether your operation uses deep-lug pallets, multi-nest bins, or oversized IBCs, we’ll build a system that provides consistent, high-contact cleaning without overextending water, energy, or operator labor.

Integrating Automation for Lifecycle Efficiency

To further streamline operations, Niagara Systems provides automation technologies that work in tandem with its cleaning systems to optimize efficiency across the packaging lifecycle. These include:

- Stacking and Unstacking Modules: Automatically separate and realign nested containers or stacked pallets before and after washing, eliminating manual handling and improving throughput rates.

- Integrated Inspection and Tracking: Vision systems and sensor-based tracking allow for container condition verification, barcode scanning, and digital logging—giving operators real-time insights into asset performance and usage history.

- Sustainability-Driven System Controls: From water recirculation strategies to smart heating and chemical dosing, every system is engineered to support environmental performance goals while delivering measurable ROI.

Together, these customizable and automated capabilities allow manufacturers to embed the washing process into broader production and logistics systems without creating bottlenecks or compliance risks. That means a reusable packaging workflow that’s clean, traceable, and operationally efficient from start to finish.

Let’s Engineer the Reusable Packaging Wash System Your Facility Needs

Let’s build the right system for your operation. Whether you’re managing high-volume pallets, precision-engineered totes, or mixed-format reusable packaging, Niagara Systems can engineer a washer that meets your exact specifications—mechanically, thermally, and operationally.

Our team will work with you to define your cleaning requirements, container types, throughput targets, and compliance needs to design a solution that performs from day one. Contact us today to start the conversation about a custom-built washer system designed around your workflow.