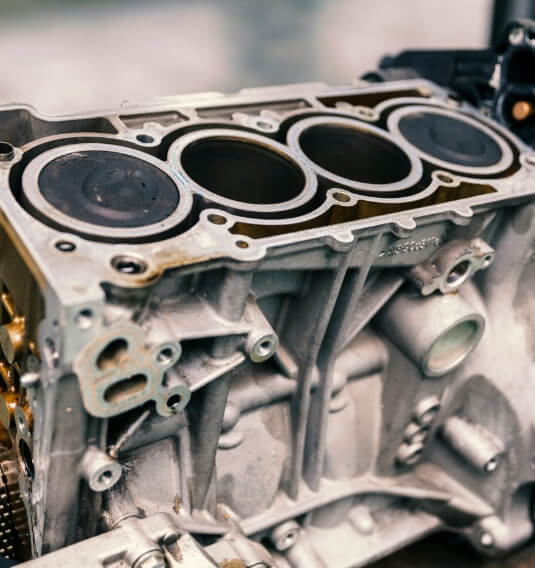

Dirty engine blocks don't stand a chance.

Niagara Systems' engine block washer solutions strip away grime, grease, oxidation, and debris, ensuring each engine block is ready for remanufacturing or assembly. In industries where cleanliness isn't just a preference but a requirement, our systems deliver the consistency and performance that keep production lines moving.

No two operations are the same—and neither are the challenges they face. Collaborate with Niagara Systems to create a custom engine washer system tailored to your operational needs.

Talk to one of our experts to discuss details today!

Get in Touch »Tough Grime, Tight Spaces, and High Stakes: Solved

The remanufacturing of engine blocks is no small task, and washing them presents its own set of challenges. Tight passageways, baked-on grime, and complex geometries make thorough cleaning a headache for many operations. Add to that the need for compliance with strict cleanliness standards, and the stakes get even higher. Miss a spot, and you risk compromising the performance or longevity of the engine—and that’s a risk no operation can afford. That’s where our engine block washer solutions come in.

The Advanced Features That Solve Your Toughest Challenges

At Niagara Systems, we understand the unique hurdles of washing engine blocks. Our systems tackle the toughest cleaning challenges with advanced features like:

- High-Pressure Precision: Targeted jets reach every crevice, blasting away contaminants that manual cleaning can’t touch.

- Eco-Friendly Filtration: Integrated filtration systems keep cleaning solutions fresh, reducing waste while maintaining peak cleaning performance.

- Heat and Detergent Synergy: High-temperature washing paired with industrial-grade detergents ensures grease, oil, and carbon buildup don’t stand a chance.

- Custom Configurations: From handling oversized blocks to adapting to unusual geometries, our washers are engineered to efficiently clean the most complex components.

- Reliable Automation: Streamline your process with systems designed to integrate seamlessly into your production line, cutting down on manual handling and ensuring consistent results.

With Niagara Systems, your engine blocks come out of the washer spotless, ready for machining, assembly, or whatever’s next. We don’t just meet industry standards—we help you exceed them.

Engine Block Washer Systems: Any Configuration, Every Solution

At Niagara Systems, we understand that every operation is unique. That’s why we create engine block washer systems in virtually any configuration to meet your specific requirements. From compact setups for small-scale operations to high-capacity washers for bustling production lines, we have the expertise and technology to design systems that fit seamlessly into your workflow.

Series 200 Tunnel Washers: Built for the Automotive Industry

Our Series 200 tunnel washers are the go-to choice for automotive professionals. Engineered for heavy-duty cleaning, Series 200 systems can handle the rigorous demands of engine block washing while maintaining compliance with the automotive industry’s strict standards.

Key features include:

- Multi-Stage Cleaning: Pre-wash, wash, rinse, and drying stages ensure a spotless finish.

- Modular Customization: Adaptable configurations to suit different block sizes, shapes, and production line setups.

- Energy Efficiency: Optimized water and detergent usage to reduce costs and environmental impact.

- Automation Ready: Integrates seamlessly with robotic loaders and conveyors to streamline operations.

Spotlight on the Series 200 Model MT23

The Series 200 Model MT23 is the ultimate solution for cleaning engine blocks. Designed with efficiency and precision in mind, this model offers unmatched performance:

- Large Throughput Capacity: The MT23 can handle high volume throughput, perfect for large and small remanufacturing facilities with demanding schedules.

- Precision High-Pressure Jets: Strategically positioned jets deliver targeted cleaning to every surface, passageway, and cavity, ensuring challenging geometries are free from debris and buildup.

- Adjustable Drying Capabilities: After the cleaning cycle, the MT23’s drying stage effectively eliminates residual moisture, ensuring engine blocks are ready for the next step in your production process.

- Advanced Filtration: The MT23 features a state-of-the-art filtration system that removes contaminants, recycles cleaning fluids, and reduces overall waste.

- Durable Construction: Built with industrial-grade stainless steel and corrosion-resistant components, the MT23 is designed to withstand daily heavy-duty use while maintaining reliability over time.

Let’s Build Your Perfect Engine Block Washer

Your operation has unique needs, and Niagara Systems is here to deliver a custom solution that meets them head-on. Whether you’re remanufacturing small batches or managing a high-capacity line, our engine block washer systems are designed to match your specs. From initial concept to installation, we work with you to engineer a washer that handles the toughest cleaning challenges.

Connect with us today, and let’s create a system that keeps your production line running clean, compliant, and unstoppable.

Frequently Asked Questions: Engine Block Washer Systems

If you have any questions or would like to learn more about our engine block washer solutions, check out our helpful FAQ.

What types of contaminants can an engine block washer system remove?

Engine block washer systems effectively remove grease, oil, carbon deposits, rust, dirt, and machining debris. Advanced models also tackle tough residues from remanufacturing processes, such as sealant or gasket material.

How do I determine the right size of an engine block washer for my facility?

The size depends on your operational throughput, engine block dimensions, and available floor space. Our team conducts a detailed analysis of your needs to recommend or design a washer that integrates seamlessly into your workflow.

Are there options for integrating an engine block washer into an existing production line?

Absolutely. Our washers are designed with modularity and automation in mind, making integration with conveyors, robotic systems, and other equipment straightforward. We also offer consultation to ensure seamless implementation.