*Special instrumentation is needed to validate this test.

There are two basic tests for cleanliness that are generally accepted. One test is for particulate and the other for surface tension.

The particulate test measures the amount of particulate on the part before and after washing. This is done by weighing the part before and after washing. The part is weighed and then dipped in a solvent solution like acetone. Then it is weighed again. The acetone is poured through filter paper and the particulate is trapped. Then the size of the particulates left on the part may be measured using a microscope.

The surface tension test can be done in some different ways. The simplest is to see if the water will “sheet” on the part or if it draws-up into drop. This is a visual test and good for many applications. Sheeting is good, drops are bad.

A more sophisticated test is the dyne test that uses a range of pens, similar to broad felt tip markers. These pens are calibrated so that when drawn over the cleaned part will either leave a solid line or a squiggly line. A solid line is what you are looking for. The pens range in calibration from 20 to 100. The higher the number, the more clean, or less surface tension in on the part.

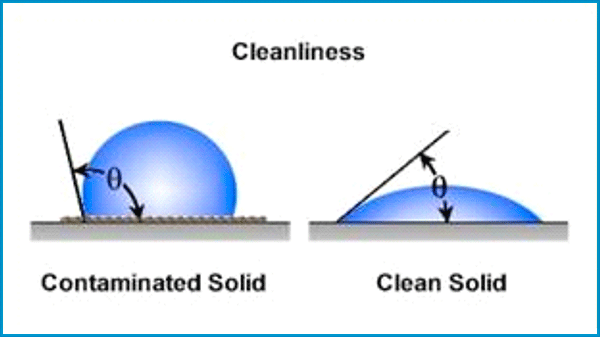

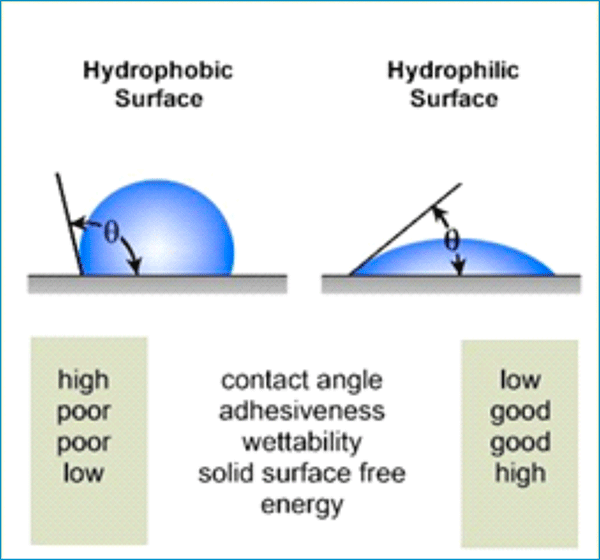

A much more sophisticated form of the dyne test measures the contact angle of a drop of water on the surface of the part which is an excellent indicator of the presence of contaminants (see images below that illustrate this concept).

Finally, some people use a “white glove” test which is, as the name implies, a white glove drawn over a clean part to see if there is any “dirt”.