- Keeping it clean since 1934!

- (440) 259-2500

- [email protected]

Manual vs. Automatic Pallet Washing: Why You Should Upgrade to an Industrial Pallet Washer

April 24, 2023

Selecting the Best Automotive Parts Washer: 6 Factors to Consider to Ensure You Make the Right Investment

October 6, 2023

How Does Ultrasonic Cleaning Work? The Science Behind the Process

Industrial cleaning processes have undergone significant advancements over the years, leading to more efficient, thorough and environmentally-friendly methods. Among these, ultrasonic cleaning stands out due to its effectiveness, speed and ability to clean intricate and hard-to-reach areas. But how does ultrasonic cleaning work? And what makes it such a popular choice in various industries?

Ultrasonic cleaning is a process that utilizes high-frequency sound waves and a suitable cleaning solution to eradicate dirt and contaminants from objects. This innovative cleaning method has found its place in numerous industries, from automotive to healthcare, electronics to aerospace. Its growing popularity is attributable to the ultrasonic cleaning machine’s ability to deliver a high standard of cleanliness, unmatched by traditional cleaning methods. In this article, we will delve into the fascinating science behind ultrasonic cleaning, exploring its unique process, underlying principles and rising popularity in industrial settings. We will also discuss the features and benefits of Niagara Systems’ ultrasonic cleaning machines, your top choice for industrial ultrasonic cleaning equipment.

The Ultrasonic Cleaning Process

The ultrasonic cleaning process harnesses the power of sound waves and the physical properties of liquids to achieve a deep and thorough clean. It might seem complex at first glance, but the science behind it can be broken down into two fundamental concepts: the propagation of ultrasound waves and the phenomenon of cavitation.

The Role of Ultrasonic Waves

Ultrasonic cleaning starts with the generation of ultrasound waves — high-frequency sound waves typically above the range of human hearing. In an ultrasonic cleaning machine, these waves are generated by a component known as the transducer. When electricity is applied to the transducer, it vibrates at a high frequency, creating sound waves that travel through the cleaning solution.

The Principle of Cavitation

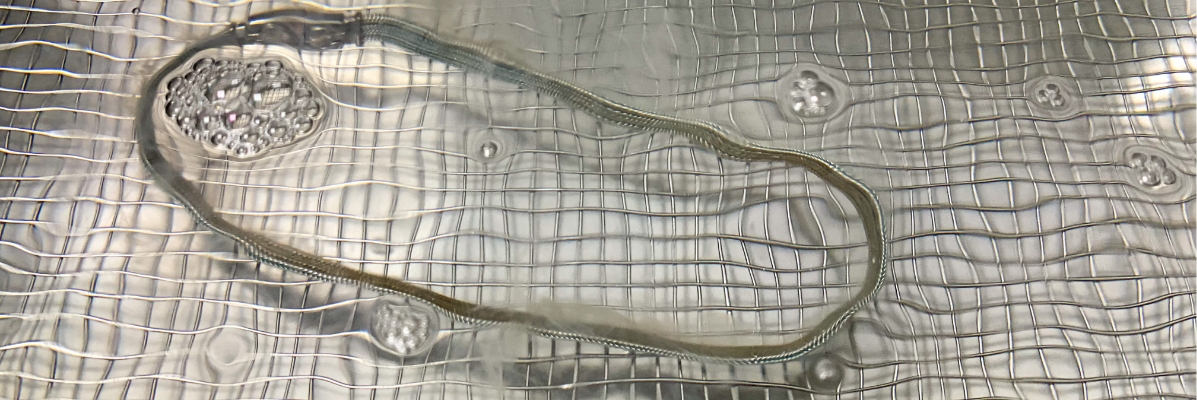

The second concept, cavitation, is what makes ultrasonic cleaning so effective. As the sound waves move through the cleaning solution, they create a series of compression and expansion cycles. During the expansion cycle, tiny bubbles or “voids” are formed in the liquid. As the compression cycle follows, these bubbles collapse or “implode,” producing a tremendous amount of energy and heat.

This implosion has a microscopic but powerful scrubbing effect on the object being cleaned. The high-energy bubbles get into every nook and cranny, effectively dislodging dirt and contaminants, even from areas that would be difficult or impossible to reach with traditional cleaning methods. This thorough, deep cleaning sets ultrasonic cleaning apart from other cleaning processes.

What Is an Ultrasonic Cleaner?

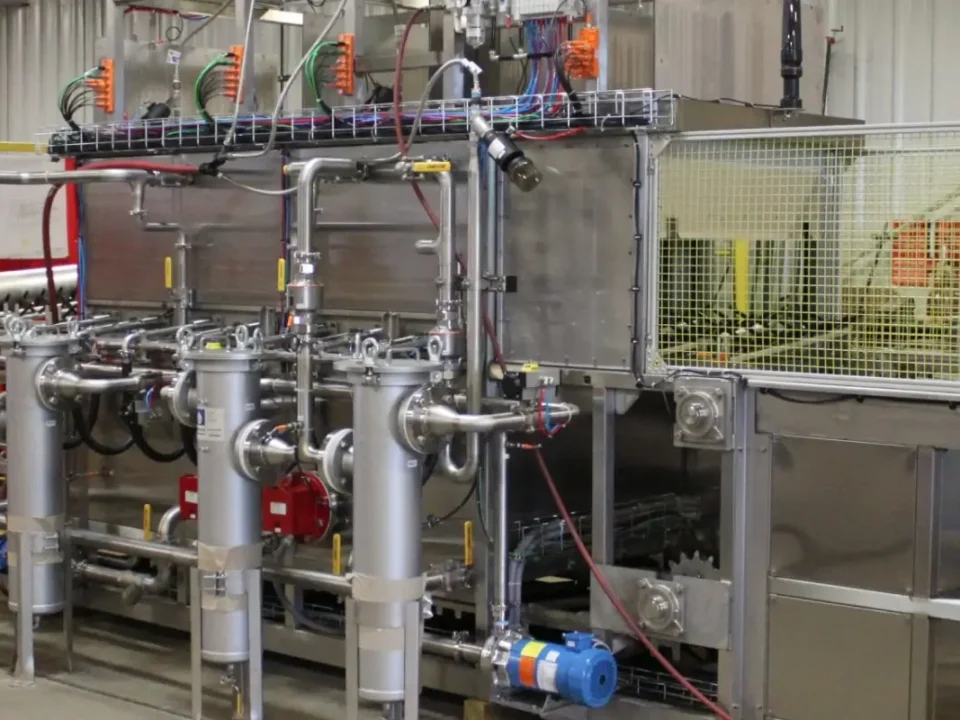

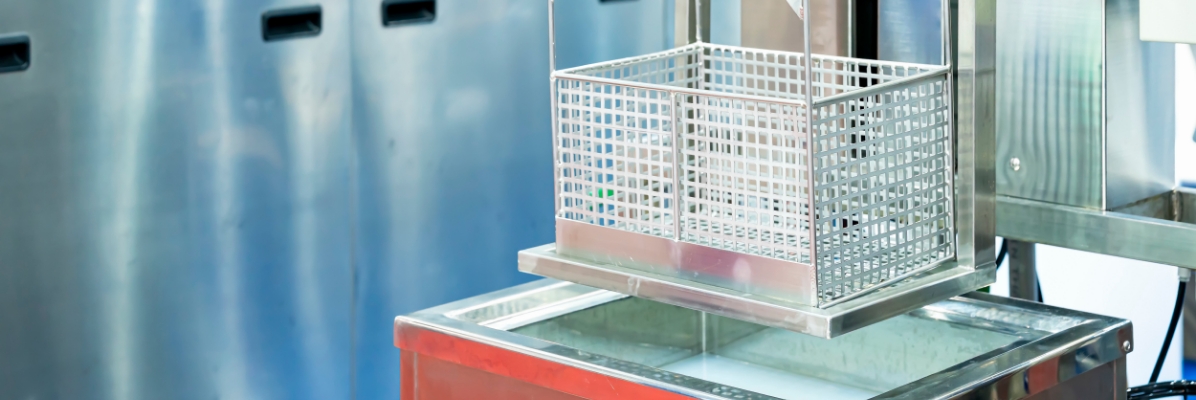

An ultrasonic cleaner, or ultrasonic cleaning machine, is a device that utilizes ultrasonic technology to clean items effectively and efficiently. While specific designs may have different components, at its core, it consists of a tank to hold the cleaning solution, a transducer to generate the ultrasonic waves and a generator to power and control the transducer.

The cleaning tank is filled with a suitable cleaning solution, which can range from plain water to specialized cleaning solvents, depending on the item being cleaned and the type of contamination. The object to be cleaned is fully submerged in this solution.

The transducer, powered by the generator, is the heart of the ultrasonic cleaner. When electricity is supplied to the transducer, it vibrates at a high frequency, creating ultrasonic waves that travel through the cleaning solution.

The process of creating and collapsing microscopic bubbles (cavitation) is central to the operation of an ultrasonic cleaner. As these bubbles implode, they release significant energy, creating an intense scrubbing action that removes dirt and contaminants from surfaces and crevices.

How Does an Ultrasonic Cleaner Work?

Operating an ultrasonic cleaner involves a series of steps:

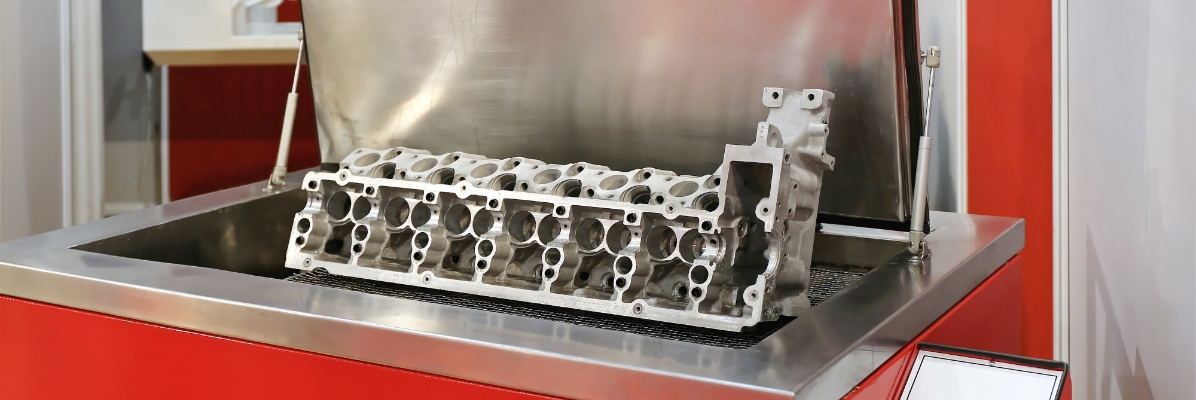

- Preparation: The item to be cleaned is prepared, which might include removing gross contaminants. It is then placed in the tank of the ultrasonic cleaner.

- Filling the tank: The tank is filled with a cleaning solution suitable for the item and the type of contamination.

- Setting the parameters: The cleaning cycle’s parameters, such as temperature and duration, are set based on the cleaning requirements.

- Ultrasonic cleaning cycle: The machine is turned on, and the ultrasonic cleaning process begins. The transducer generates ultrasonic waves that create cavitation bubbles to remove dirt and contaminants from the item.

- Rinsing and drying: After the cleaning cycle, the item is removed from the cleaner, rinsed to remove the cleaning solution and any loosened debris and dried.

Ultrasonic Cleaners Are Used to Aid in Industrial Applications

Ultrasonic cleaners have a wide range of applications across various industries due to their efficiency, effectiveness and versatility. Here are just a few examples:

- Manufacturing: Ultrasonic cleaners are used to clean and prepare parts before assembly, ensuring optimal performance and longevity of the final product.

- Automotive: In the automotive industry, they are utilized to clean intricate components such as carburetors, fuel injectors and gears.

- Aerospace: Ultrasonic cleaning machines ensure the precision cleaning of aircraft components, contributing to safe and efficient operations.

- Electronics: Ultrasonic cleaners are used to clean electronic parts and PCBs, removing flux, dust and other contaminants that can affect performance.

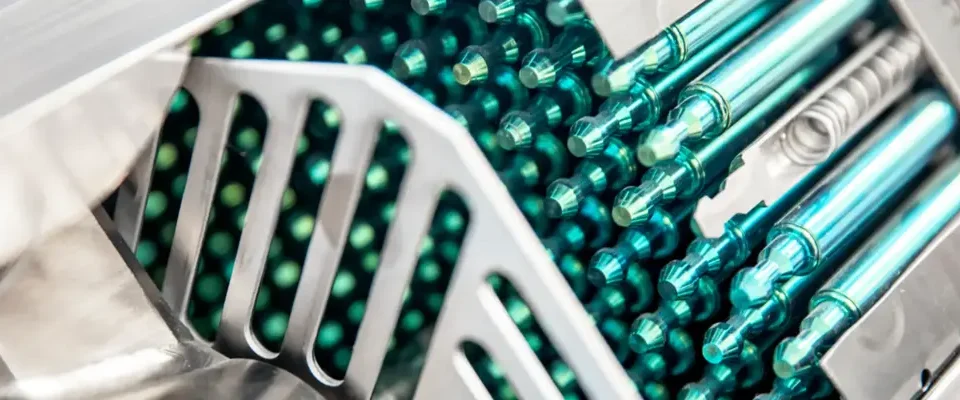

- Healthcare: Ultrasonic cleaning plays a critical role in sterilizing surgical instruments, dental tools, and other medical equipment.

- Jewelry: Ultrasonic equipment is often used to clean and restore jewelry, achieving a level of cleanliness difficult to obtain by other means.

In each of these applications, the ultrasonic cleaning process ensures a level of cleanliness often unmatched by traditional cleaning methods, making it a preferred choice in these and many other industries.

The Advantages of Ultrasonic Cleaning in Industrial Settings

Ultrasonic cleaning is rising in popularity in industrial settings — and for good reason.

- This technology offers significant benefits over traditional cleaning methods.

- It delivers superior cleaning results, especially for items with complex geometries or hard-to-reach areas.

- It’s efficient, reducing cleaning times and thus increasing productivity.

- Ultrasonic cleaning is environmentally friendly, often using less harsh chemicals and reducing waste.

With these advantages, it’s no surprise that more and more industries are choosing ultrasonic cleaning as their go-to cleaning process.

Why Choose Niagara Systems for Your Industrial Ultrasonic Cleaning Equipment?

Choosing the right partner for your industrial ultrasonic parts cleaning needs is crucial, and Niagara Systems is a name you can trust. With a legacy of quality and innovation, we offer superior ultrasonic cleaning machines designed to meet your specific cleaning requirements. Our industrial parts washer machines are robust, reliable and engineered for high performance, ensuring that you get the most effective cleaning results every time.

When you choose Niagara Systems, you’re not just getting a product — you’re gaining a partner dedicated to ensuring your ultrasonic cleaning processes are tailored to your needs.

Order Your Ultrasonic Cleaning Machine Today

Ultrasonic cleaning has revolutionized the way industries approach their cleaning processes. By leveraging the power of high-frequency sound waves, ultrasonic cleaners deliver a level of cleanliness that is difficult to match with traditional cleaning methods.

Niagara Systems stands at the forefront of this technology, offering superior ultrasonic cleaning machines coupled with unmatched customer support. When you partner with us, you can be confident in the quality, efficiency and effectiveness of your cleaning processes. Contact Niagara Systems today to request a quote and make the switch to ultrasonic cleaning.