Parts cleaning is a critical process in the aerospace sector. Aerospace components, from simple fittings to complex turbines, must be free of contaminants like oil, grease, and carbon build-up that can cause severe issues and safety hazards. That's why Niagara Systems is so dedicated to providing the industry's best industrial aerospace parts cleaning systems. Our advanced parts cleaning machines ensure planes, jets, and helicopters are free from contaminants–which is essential for maintaining safety and compliance with FAA standards.

Niagara Systems understands that aerospace parts cleaning is not a one-size-fits-all process. That's why we offer custom-built washers tailored to your specific requirements. We'll work with you to design a custom washer that fits perfectly into your process. Request a free quote to see what we can do.

Get a Quote »

Advanced Technologies in Aerospace Parts Cleaning

Aerospace parts cleaning relies on advanced technologies to ensure that every component meets the high standards for safe and efficient operation. Niagara Systems incorporates state-of-the-art methods into our cleaning machines to provide superior results for aerospace cleaning services. Here are some key technologies we utilize.

Ultrasonic Cleaning

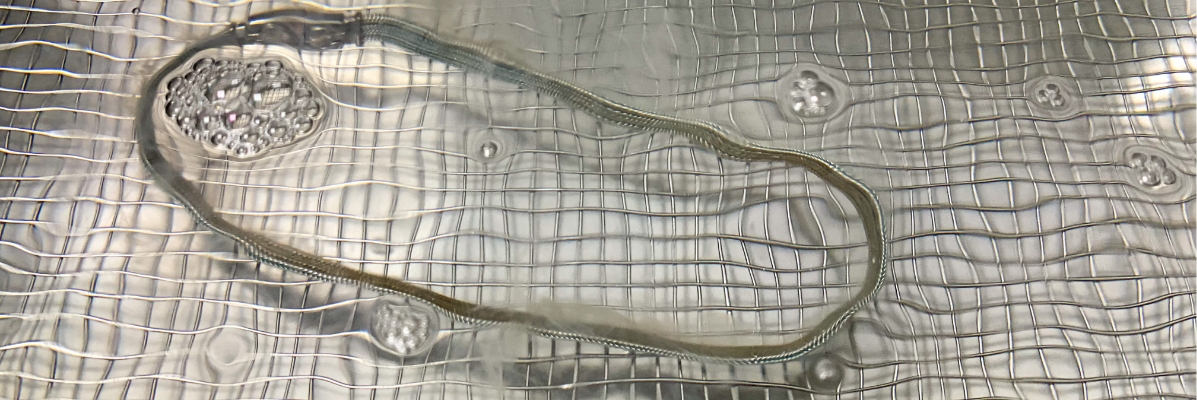

Aerospace ultrasonic cleaning is a highly effective method for cleaning intricate and hard-to-reach areas of aerospace components. This technology employs high-frequency sound waves to create cavitation bubbles in a cleaning solution.

These bubbles implode with immense force, dislodging contaminants from parts’ surfaces and internal passages without causing damage. Ultrasonic cleaning is particularly beneficial for cleaning parts with complex geometries, such as turbine blades and fuel injectors.

High-Pressure Spray Systems

Our cleaning machines feature high-pressure spray systems that use jets of cleaning solution to remove contaminants. These systems deliver precise and powerful streams of cleaning agents, effectively removing dirt, grease, and other residue from the surface of aerospace parts.

The high-pressure sprays ensure thorough cleaning, especially for larger components like airframes and engine housings.

Immersion Tank Cleaning

Immersion tank cleaning involves submerging parts in a tank filled with a specialized cleaning solution. This method allows for the complete coverage and cleaning of parts, ensuring all contaminants are removed.

The tanks can be equipped with agitation and heating systems to enhance the cleaning process. This technology is ideal for cleaning parts with complex shapes and internal cavities, such as hydraulic systems and gearboxes.

SonixClean SC-660 Ultrasonic Aerospace Parts Cleaning System

The SonixClean SC-660 is the ultimate solution for aerospace parts cleaning, designed to tackle the most challenging cleaning tasks with ease. This durable system features a tank constructed from durable INOX AISI 304 stainless steel, ensuring longevity and resistance to corrosion.

With a reinforced pneumatic platform capable of handling loads up to 3306 lb, the SC-660 makes loading and unloading heavy parts effortless. Not to mention, the integrated water flow system removes waste from the tank surface, maintaining optimal cleaning conditions.

Optional filtration, height-adjustable legs, and an insulated tank cover with a pneumatic shock absorber enhance usability and efficiency. Whether dealing with stubborn contaminants or delicate components, the SonixClean SC-660 delivers superior aerospace ultrasonic cleaning performance, ensuring your parts meet the highest cleanliness standards.

Explore Niagara Systems’ Aerospace Parts Cleaning Solutions

Discover how Niagara Systems can transform your maintenance and manufacturing processes with our advanced aerospace parts cleaning solutions. Our cutting-edge technologies and custom-designed washers ensure that every component meets the highest cleanliness and safety standards. From intricate ultrasonic cleaning to durable high-pressure systems, we have the expertise and equipment to handle all your aerospace cleaning needs.

Reach out to us today to learn more about our innovative solutions and how we can help you maintain peak operational efficiency and compliance.

Frequently Asked Questions: Aerospace Parts Cleaning

If you’d like to learn more about our aerospace parts cleaning solutions, check out the answers to our most frequently asked questions below.

What types of contaminants are typically found on aerospace parts?

Common contaminants on aerospace parts include oils, greases, carbon deposits, corrosion products, metal shavings, and other residues from manufacturing and maintenance processes. If not properly removed, these contaminants can affect the functionality and safety of the parts.

What support services does Niagara Systems provide for aerospace parts cleaning equipment?

Niagara Systems offers comprehensive support services, including installation, commissioning, training, maintenance, and repair. We also provide remote diagnostics and spare parts to ensure continuous and efficient operation of our cleaning systems. Our team is dedicated to helping clients achieve optimal performance and compliance with regulatory standards.

How is the cleanliness of aerospace parts verified after cleaning?

The cleanliness of aerospace parts is verified using various methods, including visual inspections, residue analysis, and specific cleanliness testing equipment. These tests ensure that all contaminants have been effectively removed and that the parts meet the required cleanliness standards.