- Keeping it clean since 1934!

- (440) 259-2500

- [email protected]

The Basics of Ultrasonic Parts Washers and Cleaning Systems

March 7, 2023

How Does Ultrasonic Cleaning Work? The Science Behind the Process

July 5, 2023

Manual vs. Automatic Pallet Washing: Why You Should Upgrade to an Industrial Pallet Washer

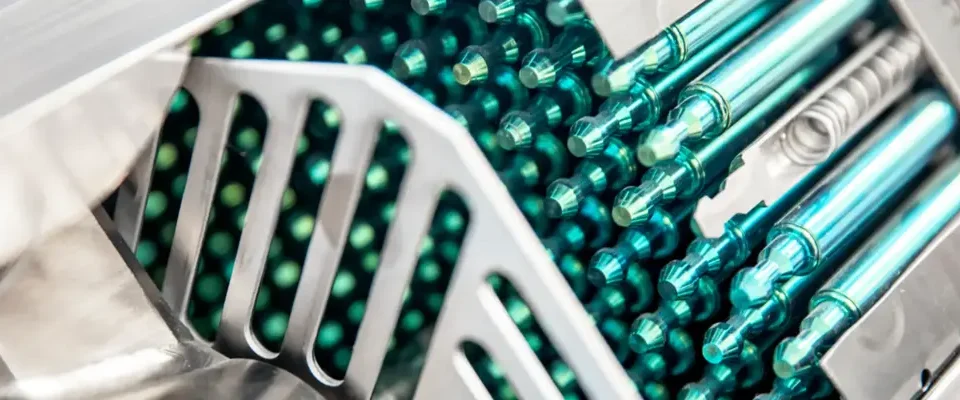

Pallet washing is an important part of maintaining a safe and hygienic supply chain. Pallets are used for shipping, storage and handling goods — and they can harbor dirt, debris, grime, germs and bacteria that can contaminate products or environments. Proper pallet washing can help prevent contamination of products, reduce the risk of health and safety hazards and extend the life of the pallets, which is an important safety measure for any operation that handles food, pharmaceuticals or anything requiring sanitary conditions.

There are two main methods of pallet washing: manual and automatic. Manual pallet washing involves cleaning and sanitizing pallets with a team of personnel and a commercial pressure washer. An automatic pallet washer is a machine that automatically cleans and sanitizes pallets. In this blog post, we’ll explore the differences between these two methods and discuss the benefits of upgrading to an automatic pallet washing machine.

Manual Pallet Washing

Manual pallet washing involves several steps, including pre-cleaning to remove loose debris and dirt, washing with water and detergent to remove stubborn stains and contaminants, rinsing with clean water, and sanitizing with chemicals to kill bacteria and other microorganisms. The pallets are then dried and inspected for any remaining debris or damage.

Pros & Cons of Manual Pallet Washing

One advantage of manual pallet washing is that it can be done with simple equipment and does not require a significant investment, making it potentially more economical for smaller operations. It also allows for greater control and customization of the washing process, as a manual pallet washer can pressure wash specific areas of the wood or plastic pallet that require more attention.

However, manual pallet cleaning is very time-consuming and labor-intensive. The effectiveness and efficiency of manual cleaning depend largely on the operator’s skills and diligence. Achieving consistent results can also be challenging when multiple operators are involved.

Challenges of Manual Pallet Cleaning

Manual pallet cleaning can also present several challenges, including:

- There are numerous worker safety concerns related to lifting heavy pallets and being exposed to chemicals used for pallet cleaning.

- There is also a risk of inconsistent cleaning if the operator is not properly trained or if the pallet washing process is not standardized.

- Finally, manual pallet washing may not be able to handle large volumes of pallets efficiently, making it impractical for larger operations.

Factors to Consider When Choosing a Manual Pallet Cleaning System

When deciding if a manual pallet cleaning system will work for your operation, it’s vital to consider the:

- Volume of pallets that need washed

- Level of cleanliness required

- Resources available

- EH&S Concerns

- Water consumption costs

- Labor Costs

For smaller operations with fewer pallets to wash, manual pallet washing may be a practical and economical solution. However, for larger operations or those requiring a higher level of cleanliness, upgrading to an automatic pallet washing machine may be a better option.

Automatic Pallet Washing

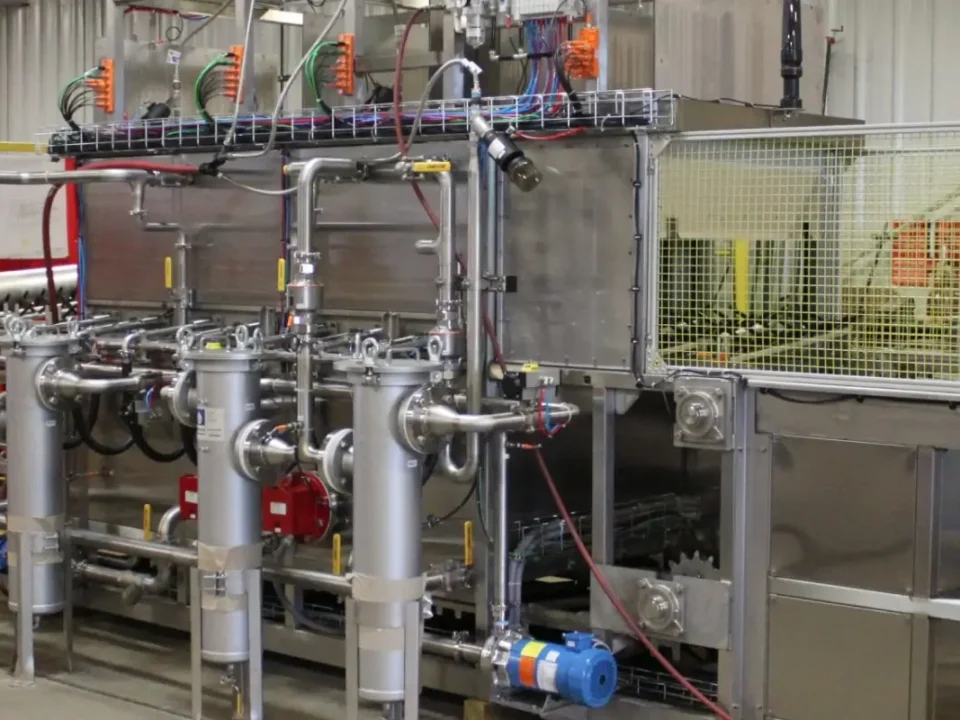

Automatic pallet washing involves the use of machines to clean and sanitize pallets, typically in large quantities. Automatic pallet washing machines can vary in size and complexity, from simple washers that use water and detergent to more advanced systems that use high-pressure jets, brushes and sanitizing sprays.

Types of Automatic Pallet Washers

There are several types of automatic pallet washers available, including conveyorized systems that move pallets through the washing process and batch systems that wash multiple pallets at once. Some machines also feature advanced technologies, such as PLC controls for highly accurate timing.

Benefits of Automatic Pallet Washing

There are many benefits of automatic pallet washing, mostly related to the efficiency it provides:

- Automated pallet washers can handle large volumes of pallets with less labor required, making them faster and more efficient than manual washing.

- Automatic pallet washing also provides more consistent and uniform cleaning results as the process is standardized.

- An industrial washer also improves worker safety by reducing the need for manual handling of heavy pallets and chemical exposure.

Factors to Consider When Choosing an Automatic Pallet Cleaning System

If you’re weighing whether or not an automatic pallet cleaning system is worth it, you’ll need to consider the:

- Volume of pallets that need to be washed

- Level of cleanliness required

- Available space

- Value of automating the process

More advanced machines with additional features typically come at a higher cost, but they may offer greater efficiency and higher levels of cleanliness, saving you time and money in the long run.

Overall, automatic pallet washing offers many advantages over manual washing and can be a valuable investment for businesses that handle large volumes of pallets or require a high level of cleanliness. By upgrading to an automatic pallet washer, companies can improve their efficiency, consistency and overall safety while ensuring their products are free from contaminants.

Comparing Manual vs. Automatic Pallet Washing Machines

It’s crucial to compare manual vs. automatic pallet washing machines to determine which method is best for your organization’s specific needs. Below are some of the main points of comparison.

Efficiency

An automatic pallet washing machine is typically more efficient than a manual pallet washer. With automatic machines, pallets can be cleaned quickly and consistently, and the process can be automated to reduce labor requirements – which allows the end-users to reallocate labor to more revenue driving processes. In contrast, manual pallet washing can be time-consuming and labor-intensive, with a greater risk of inconsistent cleaning results.

Cost

Manual washing requires less capital investment upfront, as it can be done with simple equipment and fewer resources. However, manual pallet washing is often more expensive in the long run, requiring more labor, time, and utility consumption. On the other hand, automatic pallet washing machines need a higher initial investment but can provide significant cost savings over time due to reduced labor and increased efficiency.

Quality of Cleaning

The quality of cleaning is a critical factor to consider when comparing manual and automatic pallet washing. Manual washing can be effective, but it can be challenging to achieve consistent results. Automatic pallet washers can provide more uniform and consistent cleaning results, which can be important for businesses that require the highest degree of cleanliness.

Safety & Hygiene

Manual pallet washing can present certain safety risks, such as exposing workers to harmful materials and requiring physical exertion. Automatic pallet washing machines can improve worker safety by reducing manual handling requirements and the need for workers to come into contact with chemicals and germs. Automatic industrial washers also have sanitizing capabilities that can help ensure proper hygiene.

Sustainability

Sustainability is another crucial factor to consider when comparing manual and automatic pallet washing. Automatic pallet washers can use less water and chemicals than manual washing, making them more environmentally friendly. Additionally, by requiring less labor, automatic machines may reduce the carbon footprint of the cleaning process.

While manual pallet washing can be effective for smaller operations with fewer pallets, automatic pallet washing offers numerous benefits for businesses with larger volumes of pallets or more stringent cleanliness requirements. By considering the factors above, companies can determine which method is best suited for their specific needs.

ROI When Upgrading to an Automatic Pallet Washer

As noted, there are many benefits to choosing an automatic pallet washer for your business. But you might be turned off by the high initial investment — at first glance, it doesn’t seem like an economical choice. However, depending on the size of your operation, there is likely a significant cost savings over time. The reduced labor requirements and increased efficiency of automatic pallet washing machines result in a faster return on investment (ROI) as businesses process more pallets in less time. Additionally, the improved quality of cleaning can reduce the risk of costly product recalls.

Partner With Niagara Systems for Your Automatic Pallet Washing Machine Today

Partnering with Niagara Systems for an automatic pallet washing machine can provide your business with the technology, expertise and support you need to take your supply chain hygiene, safety and efficiency to the next level. With experience in designing and manufacturing custom washing and sanitizing systems since 1934, Niagara Systems has the knowledge and expertise to provide a solution that meets your unique needs.

By partnering with Niagara Systems, you can benefit from high-quality automatic pallet washing machines that are designed to be efficient, reliable and easy to maintain. Our machines are built with industry-leading technology, ensuring that your pallets are cleaned and sanitized to the highest standards.

Contact Niagara Systems today to discuss your needs and learn more about how our industrial pallet washers can benefit your business. With quality and customer satisfaction as our foremost concerns, Niagara Systems is the partner you can trust for all your pallet washing needs.