- Keeping it clean since 1934!

- (440) 259-2500

- [email protected]

How Does Ultrasonic Cleaning Work? The Science Behind the Process

July 5, 2023

Niagara Systems Expanding Manufacturing Facility

October 11, 2023

Selecting the Best Automotive Parts Washer:

6 Factors to Consider to Ensure You Make the Right Investment

In automotive manufacturing, imperfections can make all the difference between superior performance and potential failure – every detail matters. One crucial yet often difficult step in day-to-day operations is parts cleaning. Achieving the right level of cleanliness by hand is time-consuming and often results in inconsistencies that can compromise quality. That’s why you need a dedicated automotive parts washer to make things easier for you and your employees.

Selecting the best automotive parts washer can elevate your operation, boost efficiency, curb labor costs and, most importantly, ensure an unparalleled standard of cleanliness. However, with a massive selection of machines flooding the market, each with its own set of promises, navigating the choices can be daunting. This article outlines the six essential factors you’ll need to weigh to ensure you find the best automotive parts washer for your needs.

The Impact of Finding the Best Parts Washer on Your Operations

Before discussing how to find the best parts washer, let’s talk about its impact on your facility. The equipment you choose in the automotive manufacturing landscape can significantly shape your production outcomes. Selecting the best automotive parts washer is more than a choice; it’s an investment in efficiency, quality and the long-term success of your operation.

- Enhanced Efficiency: The best parts cleaner is designed with the intricate needs of automotive components in mind. It’s not about dousing parts in solvents but rather using sophisticated methods to reach every nook and cranny. An automotive parts washer cabinet, for instance, can be tailored to handle various sizes and shapes of parts, ensuring each piece emerges pristine and ready for assembly. By drastically reducing the time required for cleaning, operations can maintain a steady pace, ensuring timely deliveries and meeting production targets.

- Reduced Labor Costs: Manual cleaning is labor-intensive and often inconsistent. When you switch to an advanced automotive parts washer, you ensure cleanliness while freeing up your workforce. A single individual can operate the washer rather than multiple technicians laboriously scrubbing parts, allowing others to focus on tasks that add more value to the production process.

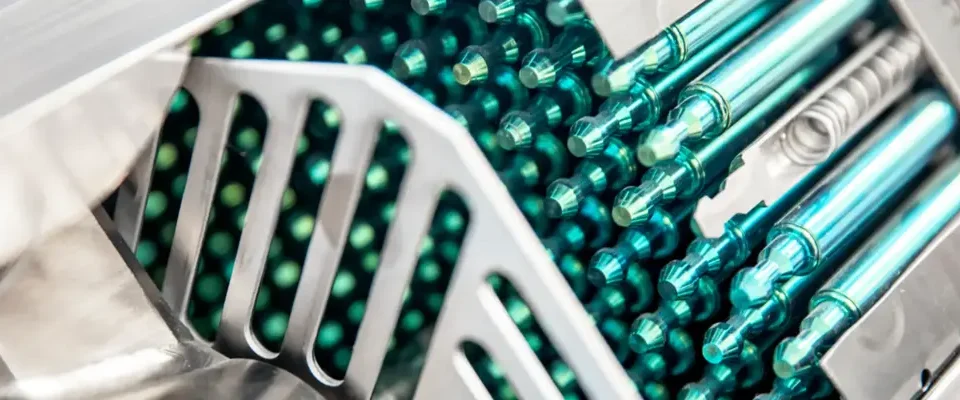

- Superior Cleanliness: At the heart of everything, cleaning automotive parts is a precise science. The best automotive parts washer is engineered to eliminate all contaminants, from stubborn greases to minuscule debris. This ensures that each component integrates seamlessly into the final product, performing at its peak and significantly reducing the risk of malfunctions or recalls due to contamination.

6 Factors to Consider When Choosing Your Automotive Parts Washer

As you search for the best automotive parts washer for your facility, several considerations will guide your decision-making. The myriad of automotive parts washer machines on the market can seem overwhelming. Still, focusing on your specific needs and industry requirements allows you to make an informed and advantageous choice.

1. Type of Contaminants

The nature and composition of residues present on the parts are crucial determinants. Whether you’re dealing with oil, grease, metal shavings, chemical residues or volatile organic compounds, the best parts cleaner will be designed to tackle these specific contaminants effectively.

2. Part Size & Shape

Automotive components vary widely in terms of size and complexity. For example, an automotive parts washer cabinet may be suited for certain components, while other machines might cater to larger or intricately shaped parts. Choosing equipment that can handle the diverse parts you’re processing is essential.

3. Production Volume

Consider the number of parts you’ll be cleaning daily or weekly. Automotive parts washer machines come in various capacities, and selecting the right size ensures optimal efficiency without over-investing in a capacity you don’t need.

4. Environmental Considerations

Modern consumers and regulations increasingly favor eco-friendly operations. The best automotive parts washer will deliver impeccable cleaning results and incorporate features that reduce waste, minimize water usage, or employ eco-friendly cleaning agents.

5. Budget & ROI

While it’s tempting to focus solely on the upfront costs, it’s crucial to consider the long-term value. The best parts cleaner might require a more substantial initial investment, but the efficiencies and savings it brings in terms of reduced labor, minimized rework and fewer defects can offer a compelling return on investment.

6. Reliability and Maintenance

In the fast-paced world of automotive manufacturing, downtime is a costly setback. Ensure that the automotive parts washers you’re considering are known for their reliability and have a track record of requiring minimal maintenance.

Learn More About Our

Automotive Parts Washer Offerings

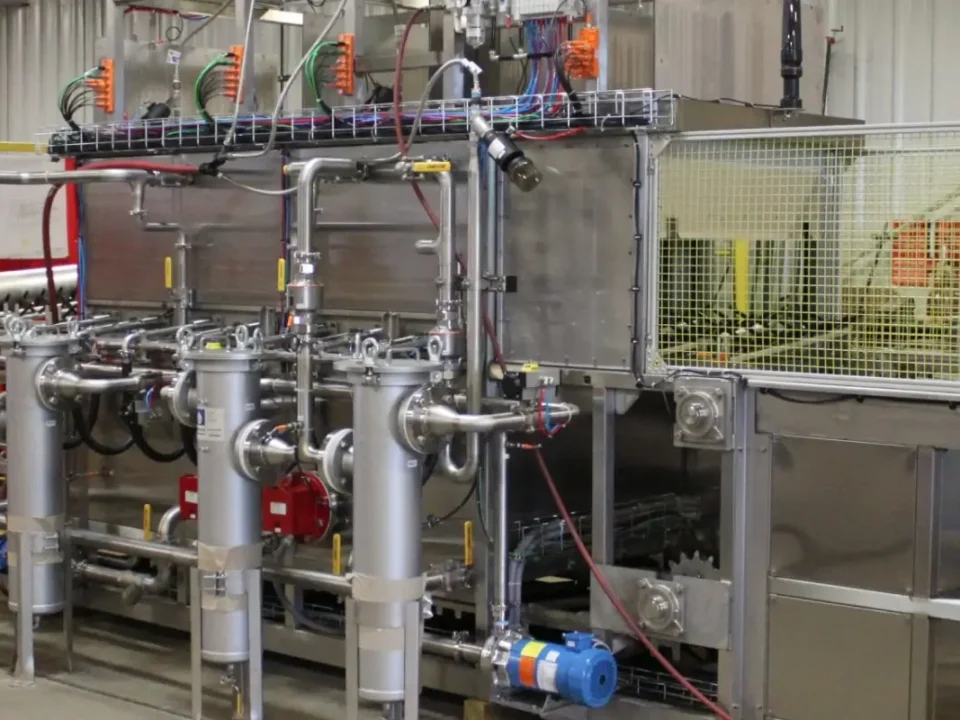

Niagara Systems stands out as a beacon of quality, innovation and tailored solutions in a marketplace brimming with options. We don’t just offer automotive parts washer machines; we provide solutions crafted specifically for the unique demands of the automotive industry. When it comes to high efficiency and resilience, our tunnel washer machines rise to the occasion. Often hailed as the best choice for cleaning automotive parts, they’re perfect for high-production and medium-volume applications.

Frequently Asked Questions: Finding the Best Parts Washer

If you have any questions or need more information about finding the best parts washer for your automotive operation, check out the answers to our most frequently asked questions below.

Are There Different Types of Automotive Parts Washers?

Yes! There are various types of automotive parts washers, including tunnel washer systems, carousel parts machines, automotive parts washer cabinets and custom washers. The best choice depends on your production volume, the size and complexity of parts and specific cleaning requirements.

Can I Use Any Cleaning Solution in My Automotive Parts Washer?

No. Only use cleaning solutions recommended or approved by the manufacturer. Different automotive parts washers are designed to handle specific solvents and detergents. Using the wrong solution can damage the machine or compromise the cleaning process.

How Do I Maintain My Automotive Parts Washer?

Regular maintenance involves checking and replacing the cleaning solution, inspecting the machine for wear or damage, and cleaning or replacing filters. Always refer to the manufacturer’s guidelines for detailed maintenance instructions specific to your machine.

Find the Best Automotive Parts Washer for Your Facility at Niagara Systems

In the fast-paced world of automotive manufacturing, efficiency and precision are paramount. As we’ve explored, selecting the best parts washer can revolutionize your operations, ensuring consistent cleanliness, optimizing labor costs and safeguarding the quality of your final products. Niagara Systems stands at the forefront of this industry, offering tailored solutions that cater to your every need. Don’t leave the performance of your components to chance. Invest in the best automotive parts washers on the market. Trust in Niagara Systems, where quality meets innovation. Request a quote today and take your cleaning processes to the next level.