- Keeping it clean since 1934!

- (440) 259-2500

- [email protected]

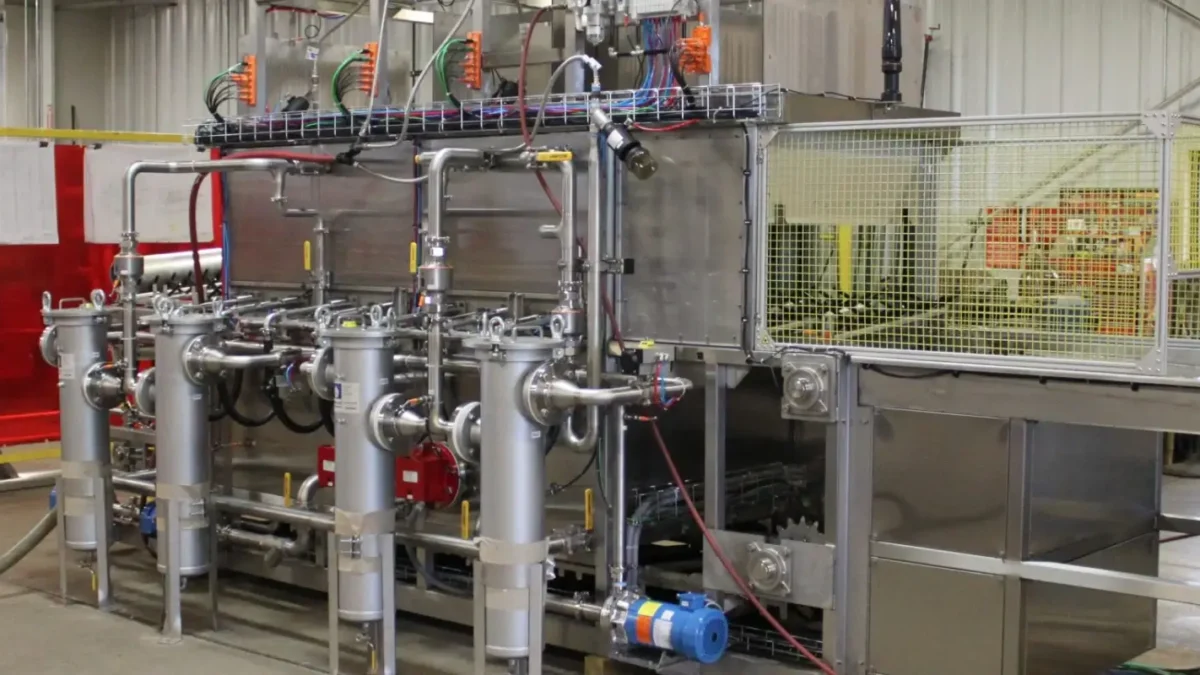

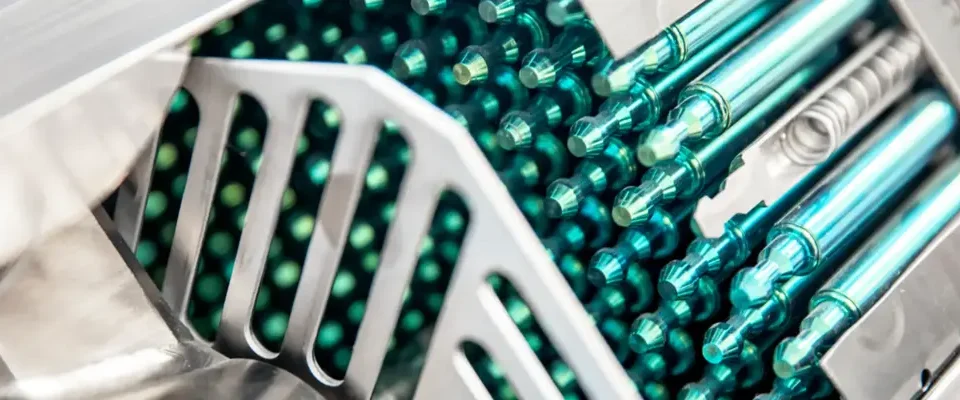

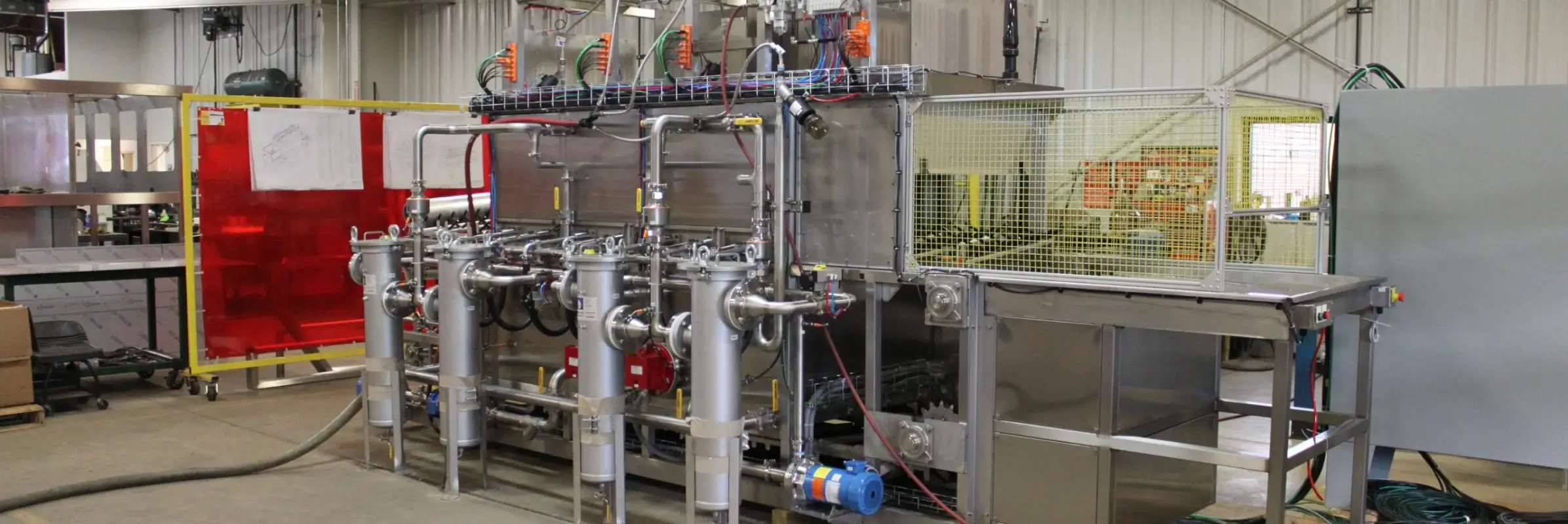

How Niagara Systems Built a Custom Washer for Nuclear Fuel Rods

June 25, 2025

Industrial Cleaning Solvent vs. Aqueous Cleaning Solution: What’s Best for Your Application?

Industrial cleaning depends on chemistry as much as it depends on the parts washer. Oils, greases, coolants, particulates, and stubborn residues all behave differently, which is why many operations compare solvent vs. solution when choosing the right cleaning method. Once you understand what a solvent is, what a solution is, how solvation works, and why certain soils respond to one chemistry more than another, it becomes much easier to choose a cleaning approach that matches your application.

What Is a Solvent?

A solvent is a liquid that dissolves, loosens, or lifts another substance from a surface. In industrial cleaning, solvents are often used to break down hydrophobic soils, such as oils, greases, waxes, machining fluids, and carbon-rich residues. Mineral spirit cleaning solvents, alcohol blends, ketones, and other organic liquids are common examples.

A solvent-based cleaner works by surrounding soil molecules and weakening the forces that hold them together. This interaction creates a pathway for the residue to dissolve or disperse, making it easier to remove during rinsing or drying. Solvents are valued for their strength, speed, and ability to handle heavy, stubborn contamination.

What Is an Aqueous Solution?

An aqueous solution forms when a solute dissolves completely into a solvent. In many industrial cleaning processes, water acts as the solvent while detergents, surfactants, builders, and other additives become the solutes. When these ingredients mix into the water, they create an aqueous solution with properties tailored for cleaning.

Aqueous cleaning solutions are typically free from volatile organic compounds (VOCs), can wet surfaces more effectively, break oils into tiny droplets called micelles, lift particulates, and hold loosened soils in suspension. This ability to modify water’s natural behavior is what allows aqueous cleaning solutions to work on metals, plastics, composites, and a wide range of manufactured components.

A Quick Look at Solvation

Solvation describes the way solvent molecules surround and interact with a contaminant at the molecular level. This interaction loosens the soil’s grip on the surface so it can lift away, disperse, or dissolve. In industrial cleaning, solvation explains why certain residues respond immediately to a cleaning solvent while others require the additives found in aqueous cleaning solutions.

What Is the Difference Between a Solvent and a Solution?

The difference between a solvent and a solution becomes easier to understand when you look at how each behaves during actual cleaning tasks. The real distinction shows up in performance, handling, and material compatibility.

Evaporation, Rinsing, and Drying

Solvents tend to evaporate quickly. Alcohols and other fast-drying liquids often require little or no rinsing, which helps shorten the total cleaning cycle.

Aqueous solutions behave differently. Because water does not evaporate as rapidly, these cleaners usually need a rinse stage and a controlled drying step to remove leftover moisture or additive residue.

Environmental and Health Considerations

Some solvent-based options contain volatile organic compounds that can pose health and environmental concerns. These vapors require proper ventilation and handling during use.

Aqueous solutions avoid most VOC-related risks, although extreme pH cleaners still call for caution. Their overall profile makes water-based versus solvent-based decisions easier in environments where air quality or regulatory compliance plays a major role.

Additives and Material Compatibility

Aqueous cleaning solutions rely on additives to give water more cleaning power, but they are not compatible with every material. Certain metals, plastics, or coatings can react negatively if the formulation is too aggressive.

Solvent-based cleaners bring their own compatibility considerations, often stripping away paint and certain finishes due to their aggressive chemistry.

Water-Based vs. Solvent-Based Cleaning

Water-based and solvent-based cleaners behave differently throughout the entire cleaning process, not just during soil removal. Their chemistry affects temperature needs, bath maintenance, waste streams, and long-term operating expectations. Understanding these broader differences helps clarify which approach fits specific industrial goals.

Operating Temperature and Energy Use

Temperature changes how each chemistry performs:

- Aqueous cleaning solutions usually work best at elevated temperatures. Warmer water helps detergents and surfactants perform as intended, which often means higher energy demand during long production cycles.

- Solvent cleaners generally function at lower temperatures. Many mineral spirit cleaning solvents remain effective at room temperature, which can reduce energy use in certain workflows.

Bath Life and Maintenance Patterns

Bath stability shifts depending on soil type and chemistry:

- Aqueous solutions collect oils, solids, and additives over time. Without proper filtration or skimming, the bath can lose efficiency and require periodic replacement.

- Solvent baths behave differently. Their cleaning strength remains more stable until soil loading reaches a certain point. Some facilities use reclamation or distillation to extend solvent life and control waste volume.

Waste Handling and Disposal

Different chemistries create different waste streams:

- Water-based cleaners create wastewater that can contain emulsified oils, fines, and traces of additives. Treatment steps such as separation, filtration, or pH adjustment are often needed before disposal.

- Solvent-based cleaners form a concentrated waste stream. Although the volume is smaller, proper containment, labeling, and disposal are essential for compliance with environmental regulations.

Process Consistency and Repeatability

The predictability of the cleaning process varies with each approach:

- Aqueous cleaning solutions can be adjusted by changing the concentration of surfactants or builders. This flexibility helps tune the cleaning strength for different materials or soil loads.

- Solvent-based cleaners are more predictable from batch to batch because the chemistry remains uniform. This can be useful when the same oily or resinous residue appears throughout the production line.

Surface Preparation and Downstream Steps

Each method prepares the part differently for what happens next:

- Water-based cleaners often leave parts ready for rinsing and final drying, which supports operations that need residue-free surfaces for inspection or assembly.

- Solvent-based cleaners prepare parts for coatings, adhesives, bonding, or finishing processes. Certain solvents remove films that interfere with surface treatments, which is why they remain common before painting or welding.

Choosing Based on the Part, Not Just the Soil

Material type plays a major role in selecting a cleaning method:

- Aqueous cleaners suit metals, plastics, or substrates that tolerate water contact and benefit from a mild or adjustable formulation.

- Solvent-based cleaners fit components designed to handle stronger organic liquids and situations where rapid drying supports fast production cycles.

These differences go beyond how each chemistry interacts with soil. They outline what water-based versus solvent-based cleaning looks like during daily operation, which is often the deciding factor when choosing a solvent or aqueous parts washer for an industrial environment.

Choosing the Right Chemistry for Your Application

The best cleaning approach starts with understanding the part, the soil, and the conditions surrounding the process. Each application places unique demands on the chemistry, so the decision between aqueous cleaning solutions and cleaning solvents depends on more than soil type alone.

Know the Soil You’re Removing

Different contaminants respond to different chemistries.

- Oils, machining fluids, waxes, and dense grease often align with solvent-based cleaners.

- Mixed soils, fines, oxides, or water-soluble residues tend to clean well in aqueous solutions supported by surfactants or builders.

Consider the Part and Its Materials

Parts made from aluminum, brass, certain plastics, or composites may require mild aqueous solutions to avoid surface changes. Parts designed to tolerate organic liquids or rapid drying cycles can often be paired with solvent-based cleaners.

Account for Process Speed and Production Volume

Facilities running continuous shifts or high-throughput lines may prefer chemistry that fits shorter cycle times or simplifies maintenance. Operations focused on precision, assembly readiness, or residue-free finishes may lean toward controlled aqueous baths with predictable rinsing stages.

Evaluate Environmental and Facility Requirements

Some industries prioritize lower VOC emissions, reduced odor, or safer handling. Aqueous cleaners often meet these goals. Other environments rely on solvent options for downstream finishing steps or unique surface preparation needs.

Think About Long-Term Maintenance

Aqueous systems involve bath monitoring, filtration, and periodic solution changes. Solvent systems may require recovery, containment, or distillation depending on facility guidelines.

Niagara Systems Supports Both Cleaning Paths

Whether you choose solvent or solution, your parts washer must support the chemistry’s strengths while managing its limitations. Niagara Systems builds washers that accommodate both approaches, giving facilities the flexibility to match their cleaning needs without forcing a single method.

Systems Designed for Water-Based Cleaning

Aqueous processes often rely on heat, flow, and controlled agitation. Niagara Systems designs equipment that supports these conditions with:

- Heated wash stages that help detergents and surfactants perform as intended

- Spray manifolds engineered to reach internal passages or complex shapes

- Filtration and separation options that help maintain bath quality over time

- Rinse and drying stages that prepare parts for inspection, assembly, or finishing

Systems Built for Solvent-Based Cleaning

Solvent cleaning requires consistent contact and responsible handling. Niagara Systems supports these workflows with:

- Configurations suited for circulation, immersion, or high-contact flow paths

- Enclosures designed to manage vapors and support safe operation

- Options for solvent containment, recovery, or reclamation

- Layouts compatible with quick-drying cycles and heavy oil removal

Application-Specific Flexibility

Different industries carry different cleaning expectations.

- Automotive, manufacturing, and remanufacturing operations may prioritize solvent-based performance on dense oils.

- Pharmaceutical, aerospace, and food processing components often require controlled aqueous processes with predictable rinsing and drying.

Niagara Systems develops equipment around these needs, making it possible to pair the right chemistry with a cleaning platform built for the demands of the application.

See How Our Customized Cleaning Systems Come Together

A short look behind the scenes can clarify what a purpose-built parts washer system can achieve. This video highlights how Niagara Systems approaches customization for facilities that rely on specific chemistries, unique part geometries, or defined production targets.

Start Building a Cleaning Workflow That Matches Your Soil Load With Niagara Systems

Industrial cleaning succeeds when the chemistry, equipment, and workflow operate in sync. Niagara Systems builds parts washers that support both solvent-based and aqueous cleaning solutions, with the flexibility to match your soil load, cycle time, material mix, and cleanliness standards. If your operation is evaluating water-based versus solvent-based methods or considering updates to an existing process, our team can walk through the requirements, review sample part data, and identify the configuration that fits your application.

Frequently Asked Questions About the Difference Between a Solvent and a Solution

How do industrial parts washers accommodate both solvent and aqueous cleaning chemistries?

Industrial parts washers support different chemistries by controlling the conditions each one requires. Aqueous processes often need heat, agitation, and dedicated rinsing stages, while solvent workflows rely on steady contact, compatible materials, and controlled vapor management. Systems designed with adjustable temperatures, configurable spray or immersion zones, and appropriate containment can operate effectively with either chemistry when matched to the right application.

Does Niagara Systems offer consultation or testing to help determine the optimal cleaning chemistry for my application?

Yes. Niagara Systems provides guidance to help pinpoint the cleaning approach that fits your part materials, soils, and performance requirements. Our team can review samples, evaluate residues, and recommend a solvent-based or aqueous path based on practical testing and real production needs.

How do automated washing systems ensure thorough solvation and consistent cleaning results?

Automated washers maintain consistency by controlling the variables that influence solvation. Temperature, flow rate, chemical concentration, and exposure time remain stable throughout the cycle. Spray manifolds, immersion zones, and agitation patterns are positioned to reach the surfaces that need attention, while filtration or separation steps keep the bath within specification. When these elements work together, the chemistry performs reliably, producing uniform cleaning results from one cycle to the next.