Industrial Washing Technical Audit

A Niagara Systems technical audit provides a comprehensive assessment of your industrial washing needs. Whether it is a new automation line, a replacement of an existing washer, or a retrofit – Niagara Systems will help your team develop a solution for your upcoming project.

Why Perform a Technical Audit?

Industrial wash systems are vital to the quality and production of your finished goods. Just like all other capital equipment and automation purchases, it is imperative you do your homework. Confidence and repeatability in your process is paramount to your customers and we will help in the development of automating your process. Understanding the utility costs, reduction of labor maintenance needs, EHS improvements and integration with systems both downstream and upstream will define the ROI – Niagara personnel will assist your team in quantifying the value of your industrial washing system.

How Niagara Parts Washers Bring Value to Companies

- Automated wash systems minimize labor needs for processes that are difficult to keep workers employed.

- Provides consistent and reliable results.

- Improves on Employee Health and Safety by minimizing operators to hazardous and laborious environments.

- Recirculation of water provides an eco-friendly and cost-effective solution to water consumption.

- Increases production and removes the bottleneck that washing process often create.

Technical Audits with Niagara Systems

Our washing experts will discuss and define requirements regarding your process, your production needs, EHS improvements, along with analyzing facility and footprint specifications to provide the industrial washing system tailored to your application.

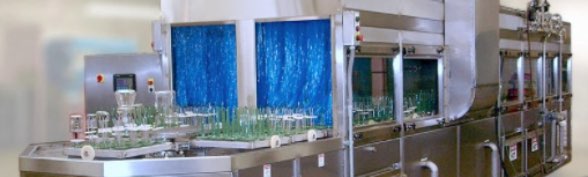

Niagara Systems is a division of South Shore Controls in Mentor, Ohio. We design, manufacture, and install industrial washing systems for a multitude of industrial applications. Niagara provides cleaning solutions for the automotive, manufacturing, aerospace, electronics, pharmaceutical, food processing, and any other industries in need of industrial washing or chemical processing.

The Niagara Benefits

For nearly 90 years, Niagara Systems has provided turnkey automation equipment to the many industries that utilize parts washing or chemical processes in their manufacturing methods. The willingness to take on complex projects throughout our years has given us knowledge that is unmatched in our field. Niagara Systems does not just provide industrial washing systems – we provide automated solutions with consistent results.

Schedule a Niagara Systems Technical Audit

If you need a crate cleaner, you’re best off getting it from the best manufacturer in the industry. Niagara Systems produces high-quality industrial crate washers that are American made, but we work with companies around the world. Reach out to us today, and you’ll be on your way to a cleaner and more efficient facility.