Brake components don’t tolerate contamination. Trapped debris, residual oils, and brake fluid can all lead to downstream failures, warranty claims, or lost time on the line. That’s why we custom-build brake washer equipment around your parts, soils, and throughput requirements. Whether you need to prep ABS valves for assembly or reclaim calipers in a remanufacturing line, we’ll build you a brake parts washer that meets your heat, chemistry, and agitation requirements.

Already have a design in mind? Request a quote today!

What We Can Build Into Your Brake Washer

Brake washer equipment has to do more than clean.

It must meet strict cleanliness thresholds, integrate with your existing workflow, and stand up to the demands of high-cycle operation.

Here at Niagara Systems, we design around your part geometry, contaminant profile, and process validation needs.

Key system capabilities and options include:

- Material Construction: Type 304 stainless steel is standard for structural components, with Type 316 available for aggressive chemistries. All welds are continuous and TIG-finished for durability and cleanliness.

- Wash System Design: Configurable impingement, spray/flood, or immersion stages, matched to part geometry and soil type. Flow rates and pressures can be adjusted for heavy carbon, machining oil, rust inhibitor, or fine particulate removal.

- Heating and Chemical Compatibility: Electrically heated tanks with PID temperature control ensure consistent wash chemistry. Systems are compatible with both aqueous and semi-aqueous solutions, including mild caustics, detergents, and passivating agents.

- Automation and Controls: Fully integrated PLC systems with HMI touchscreen interfaces, remote diagnostics, and recipe-based control for part-specific wash cycles.

- Fluid Maintenance: Inline filtration (bag or cartridge), oil coalescers, auto water level control, and conductivity sensors to monitor and maintain bath quality.

- Drying Stages: High-velocity air knives, blower-assisted drying, or optional infrared heating depending on part surface area, material, and downstream process needs.

- Ultrasonic Integration: Optional ultrasonic cleaning modules for internal bore cleaning, ideal for valve housings, ABS bodies, and master cylinder internals.

- Validation and Compliance Support: Particle count validation packages available for customers adhering to ISO 16232, VDA 19, or AIAG cleanliness standards. Data logging and traceability modules available for regulated environments.

Our brake component washers aren’t off the shelf; they’re engineered from the tank up to meet your operational goals, quality specs, and long-term maintenance strategy.

Where Our Brake Parts Washers Work Best

Brake washers aren’t limited to one industry or application.

These systems are used wherever brake components must meet tight tolerances, cleanliness specifications, or remanufacturing standards.

Common use cases include:

- Brake remanufacturing facilities: Remove oil, carbon, rust, and road debris from calipers, rotors, and master cylinders before inspection and reassembly.

- OEM and Tier 1/2 brake system production: Prepare cast and machined components for downstream coating, assembly, or packaging.

- ABS and valve body cleaning: Use ultrasonic stages and fine filtration to remove metal fines, machining lubricants, and sealant residues from precision components.

- Fleet and heavy vehicle maintenance hubs: Support high-throughput cleaning of brake parts in transit, off-road, or heavy machinery fleets with reliable, field-tested systems.

- Aerospace and performance automotive parts prep: Clean specialty brake components used in advanced or high-heat applications, where contaminants could impact safety or performance.

Our systems can be configured to support single-shift rebuild shops, 24/7 production lines, and everything in between.

Find the Right Configuration for the Job

Not sure where to start? Below are several common washer configurations we recommend based on application type, contamination profile, and operational goals.

You can also check out our machine selection guide at any time!

Cabinet-Style Brake Components Washers

Cabinet washers are ideal for low- to medium-volume operations or dedicated work cells.

Parts are loaded manually onto a turntable or custom fixture, then subjected to high-pressure spray from fixed or rotating manifolds.

Great for calipers, rotors, and master cylinders with external soils.

- Compact footprint with front or top-load options

- Recirculating wash and rinse tanks with filtration

- Optional blow-off or heated dry cycle

- Ideal for batch-based rebuild and prep workflows

Learn More About Cabinet-Style Washers »

Tunnel Washers for Brake Assembly Lines

Designed for high-throughput production lines, tunnel washers continuously move brake components through staged wash, rinse, and drying zones.

Parts are conveyed via belt, chain, or indexing systems, with built-in isolation zones to reduce cross-contamination.

- Best suited for OEM production of cast or machined brake parts

- Multiple nozzles target part surfaces from all angles

- Can integrate directly with robotic pick-and-place or packaging

- Easy maintenance access via hinged doors or roll-out sections

Learn More About Tunnel Washers »

Custom Carousel and Rotary Table Systems

When parts require multiple process steps, carousel and rotary table washers provide the flexibility to add stages without increasing footprint.

Great for cleaning, rinsing, drying, and even rust-inhibition, all within one indexed system.

- Supports ultrasonic or immersion stages where needed

- Custom tooling available for irregularly shaped components

- Built-in automation options for load/unload

Learn More About Carousel and Rotary Washers »

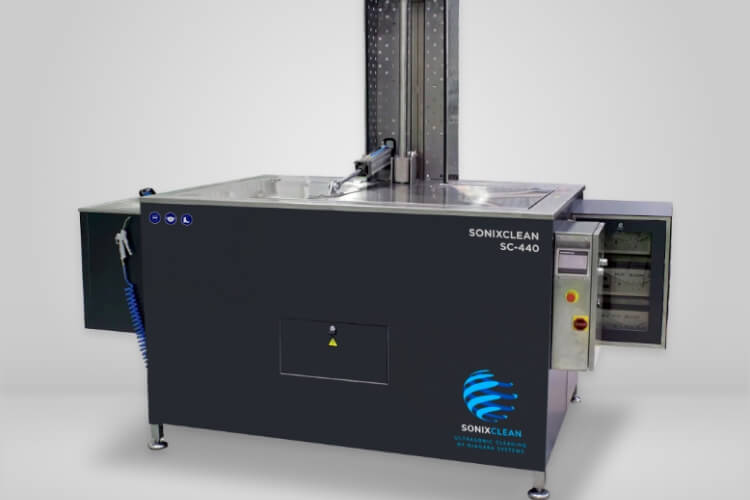

Ultrasonic Brake Washer Equipment

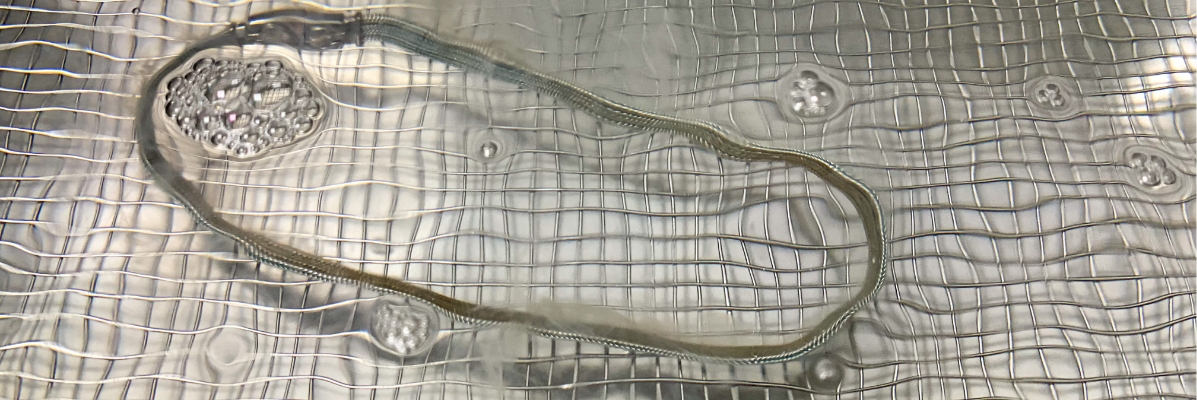

Ultrasonic cleaning uses high-frequency sound waves to agitate a liquid, allowing it to penetrate complex geometries and remove soils from blind holes, threads, and fluid channels.

Ideal for cleaning ABS housings, valve bodies, and parts with internal passages.

- Frequencies typically range from 25–40 kHz

- Effective for carbon, metal fines, and baked-on fluids

- Can be integrated into multi-stage systems

Start Building a Brake Parts Washer That Fits Your Process

If you’re tired of forcing standard equipment into nonstandard workflows, it’s time for something purpose-built. Niagara Systems works with you from concept to commissioning to design a brake parts washer that does what you need it to. Tell us what you’re cleaning, how fast you need to clean it, and what success looks like. We’ll take it from there.

Frequently Asked Questions About Brake Parts Washer Systems

Figuring out what you need from your brake washer equipment isn’t always straightforward.

Here are some of the most common questions we hear from teams evaluating custom-built solutions.

How long does a typical brake wash cycle take?

Cycle time depends on part complexity, soil load, and cleanliness requirements.

Some production environments require 30–90 second cycles, while reman applications may run 5–10 minute multi-stage cycles.

We help you optimize for both throughput and quality.

Can brake washer equipment be integrated with automation?

Absolutely. We frequently build systems that integrate with robotic arms, conveyors, vision inspection systems, and MES platforms.

Control systems can be programmed for recipe-based automation and full traceability.

What types of brake parts can your washers clean?

Our systems are configured to clean a wide range of components, including calipers, rotors, ABS valves, master cylinders, and brake lines.

Whether you’re dealing with cast, machined, or assembled parts, we build around your material, geometry, and soil profile.