- Keeping it clean since 1934!

- (440) 259-2500

- [email protected]

Conveyor Belt Washer Selection Guide

November 4, 2021

Industrial Bottle Washer Buying Guide

January 26, 2022

Tunnel Washer Buying Guide

What are tunnel washers? How do companies use tunnel washer systems in their manufacturing workflow? In this buying guide, we give an overview of tunnel parts washer machines. Discover which companies and industries utilize tunnel washers to improve efficiency, enhance sanitation and reduce physical labor.

What Is a Tunnel Washer?

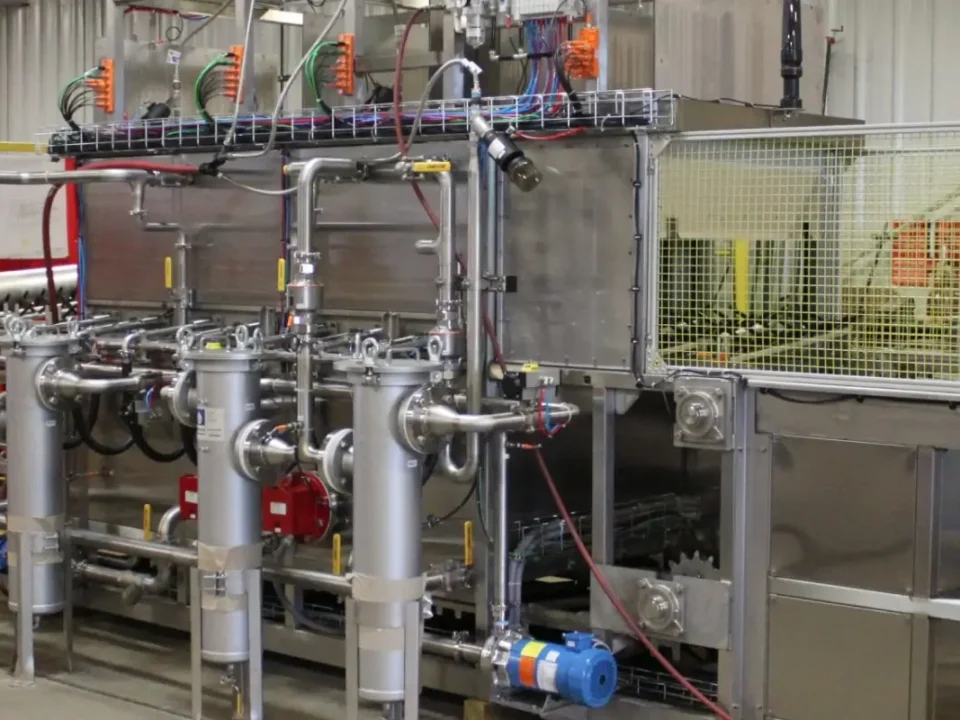

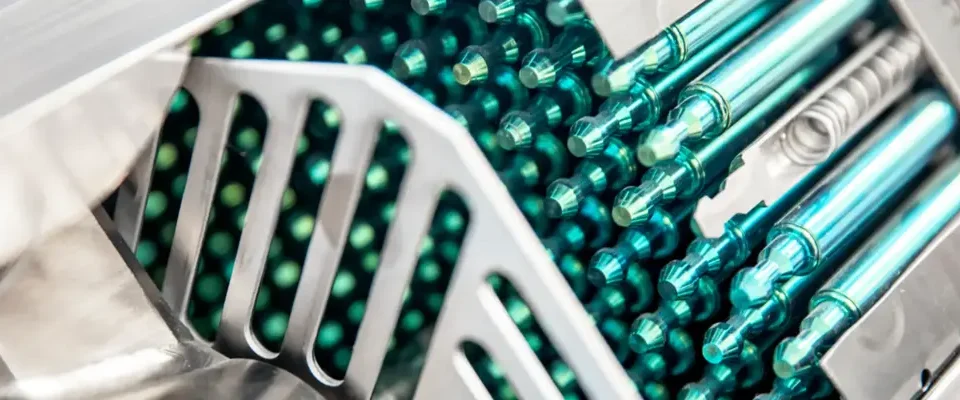

A tunnel parts washer is used to remove grease, dirt, grime, oil and other contaminants from mechanical parts. Tunnel washer manufacturers help extend the life of parts and machines by designing and engineering tunnel washers to eliminate foreign substances that can cause excessive wear and tear during operation. Tunnel washers can also be used as a value-added service to clean manufactured parts in preparation for shipping and delivery to customers or to clean crates, totes and trays used during plant operations.

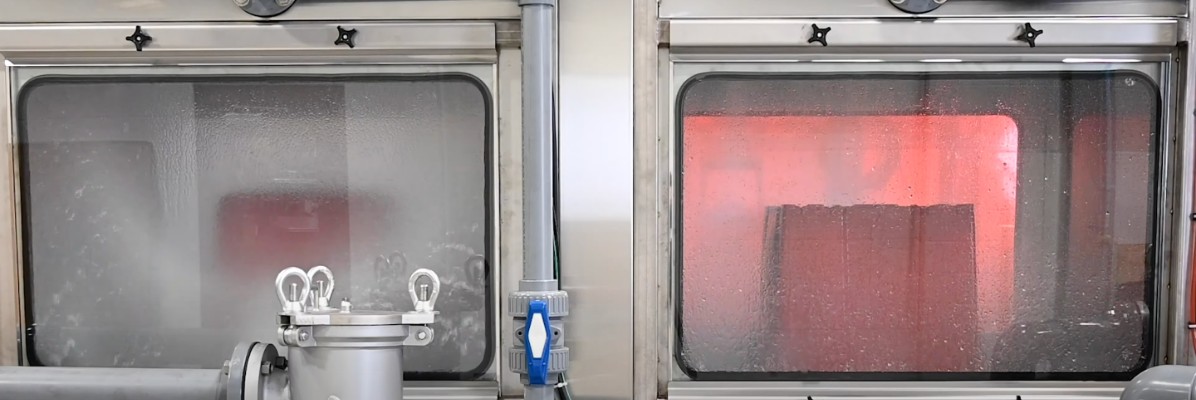

Tunnel parts washers can be aqueous or utilize solvents to clean parts and are traditionally made of stainless steel. While you can customize your own tunnel washer system to suit your needs, the basic steps needed to run them include:

- Loading

- Washing

- Rinsing

- Drying

- Unloading

While loading and unloading can be manual or automated using robotics, the process of washing, rinsing and drying is controlled by integrated systems that utilize conveyors, rollers, software and other methods to bring parts through the wash cycle.

Who Uses a Tunnel Washer System?

Tunnel washers are used in a multitude of industries for a diverse range of applications. Each one is designed according to the required treatment phases, the size and dimensions of the parts to be washed, the type of washing process and the speed at which the parts need to be cleaned. Some of the industries that utilize tunnel washers include:

- Food Service

- Manufacturing

- Automotive

- Aerospace

- Oil, Gas and Renewable Energy

- Plastics

In addition to cleaning machine parts, tunnel part washers are commonly used to clean totes, pallets, crates, bins, pans, trays, racks and other materials used in manufacturing and production facilities.

Types of Cleaning Processes Used by Tunnel Washers

Tunnel washer systems utilize two primary cleaning processes: semi-automatic and fully automated. Deciding the correct process for your company will depend on several factors including cost, labor, available space and productivity (i.e., how much product you need to clean within a given timeframe).

Semi-Automatic Tunnel Washers

Utilizes automated stages along a conveyance method to effectively clean your parts. Requires manual loading and unloading. May require inputs from an operator during the cleaning process.

Automated Tunnel Part Washers

A cleaning process that utilizes fully automated equipment. Robotics load, unload and organize parts after they have dried. Niagara Systems can develop a fully automated line utilizing our automation expertise or integrate a tunnel washer system that works with your existing robotics and other automated systems to create a fully autonomous cleaning solution.

Customizing Your Tunnel Parts Washer

Tunnel washers from Niagara Systems are highly customizable industrial cleaners. There are a number of things that can be individually or collectively changed about your tunnel washer that can radically improve or enhance your part cleaning. A tunnel washer system is made up of many different components, all of which can be adjusted or modified to meet the specific needs of your application. Here are a few elements of a tunnel washer that you should be aware of:

1. Conveyance

A conveyor system for loading or unloading can be built to your specifications. Movement between cleaning cabinets can also be modified or adjusted depending on the size, weight, dimensions, orientation and complexity of your parts.

2. Cleaning Type

Tunnel washers use either a solvent-based cleaning solution or an aqueous cleaning solution depending on your needs. The cleaning type for your application will determine the types of systems installed in your tunnel parts washer and the stages your parts go through during the cleaning cycle.

3. Controls

The ability to adjust the settings and parameters of your tunnel washer will depend on the specifications. Niagara Systems tunnel washers come with PLC controllers and HMI touch screens to program your cleaning cycle and make adjustments based on factors such as the type of parts, materials being used, number of cycles along each stage, chemicals to be used, contact time, temperature control, impact and more.

Knowing some of these parameters will help you decide on the right tunnel washer system for your company. How your cleaning process fits into the larger scope of your business operations is also important, as well as knowing the space and time considerations.

Get Started Today With a Niagara Systems Tunnel Washer

Knowing the perfect tunnel washer system for all of your applications isn’t easy. Niagara Systems is here to help. With over 80 years of experience in the industry, we are experts at developing small and large custom part washing solutions. We offer both standard washing systems and highly customized heavy-duty parts cleaning systems for a number of diverse industries. Contact us today and our experienced staff can help you get started on a tunnel washer system designed just for you.