- Keeping it clean since 1934!

- (440) 259-2500

- [email protected]

How To Choose the Best Industrial Parts Washer Based on Application

November 29, 2022

The Basics of Ultrasonic Parts Washers and Cleaning Systems

March 7, 2023

How Does a Tote Washer Machine Work?

Tote washer machines are essential tools for industrial facilities looking for effective, efficient cleaning solutions. In this article, we’ll look at the benefits of automated tote cleaning equipment. Learn about tote washers and how they are used as a regular part of industrial operations.

What Is a Tote Washer Machine?

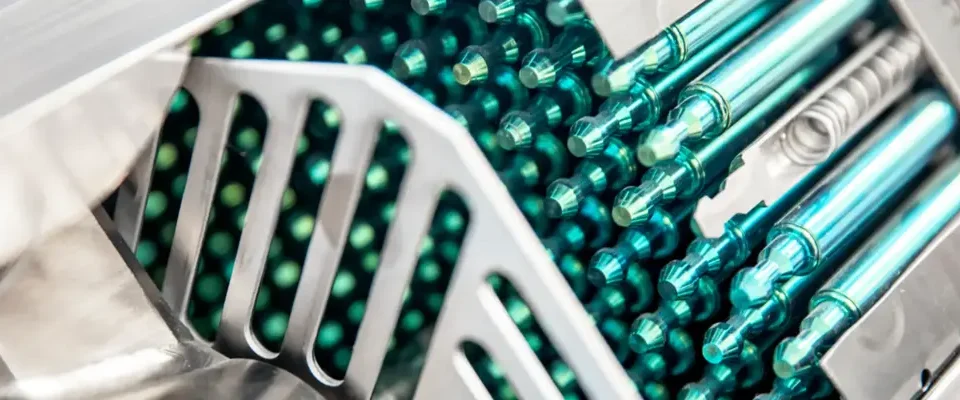

A tote washer is an industrial cleaning machine used by a variety of industries specifically to clean large containers (or totes). For businesses that use plastic totes as a part of their regular production cycle, a tote washer machine helps to streamline their daily operation.

Containers are often used for the transportation of various parts, products and bulk materials, especially in food processing plants, chemical manufacturers and other industrial facilities. These businesses require clean, sanitary totes for their materials.

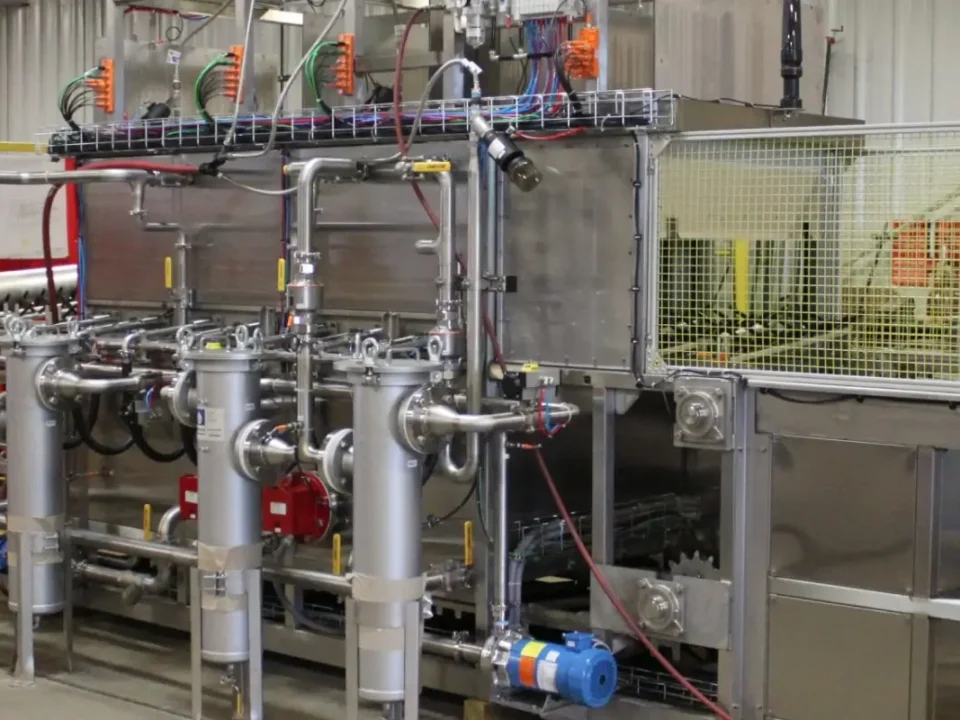

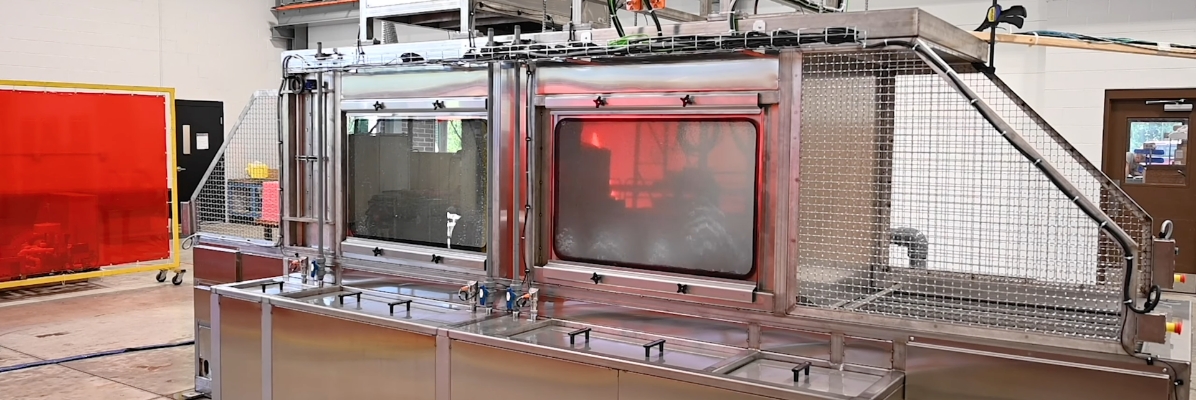

Tote washers generally consist of one or more stainless steel chambers with a conveyor belt to move totes through the cleaning process. The chamber(s) is equipped with all of the components needed to thoroughly clean your tote. Pressure washers, dispensers and heat chambers are all standard parts of a tote washer.

The Benefits of Automated Tote Cleaning Equipment

One of the prime benefits of using tote cleaning equipment is that it automates the cleaning process. For efficient and effective cleaning of large containers, tote washer machines are an ideal choice. They ensure that your containers are thoroughly cleaned and sanitized while reducing labor, water waste and time spent cleaning.

In addition to totes, cleaning equipment used for industrial sanitation can also clean large items such as drums, barrels or pallets, depending on your configuration.

The Tote Washer Process

Tote washing can be automated with a tote washer machine that requires minimal human input. Depending on your application, the configuration of your tote washer may be different from other similar machines. It can be customized to suit your specific application. Generally speaking, these are the steps involved in using a tote washer:

1. Loading Your Totes

Getting your dunnage prepared for your tote cleaning equipment can involve removing debris and placing it in a designated loading area then moving your totes onto the conveyor. The material handling and loading can be automated or done by hand.

2. Washing

Using an aqueous detergent, your tote washer machine will provide coverage for your dunnage and clean it thoroughly. Your washer is customizable for a number of different variables including water temperature, contact time, impact (jet velocity) and the chemical composition of your cleaning solution. Automatic chemical make-up ensures that the required chemistry is consistent and requires no operator interaction.

3. Rinsing & Drying

Your tote cleaning equipment will move your dunnage along the conveyor through different chambers, your tote washer machine will start with a recirculated rinse to remove the wash chemistry. After a recirculated rinse, the product typically enters a freshwater or processed water rinse which cascades back through the system. This multistage rinse allows for a very clean rinse while also minimizing overall water consumption through reutilization.

Depending on your washer bins and the required level of dryness, the drying process can be engineered in a variety of ways. The amount of heat applied will depend on your desired drying time and the materials being used. A low pressure blower paired with a heating coil can act as a convection oven. High pressure blowers are another drying method which removes excess. puddling and standing water using perfectly placed air knives throughout the drying chamber.

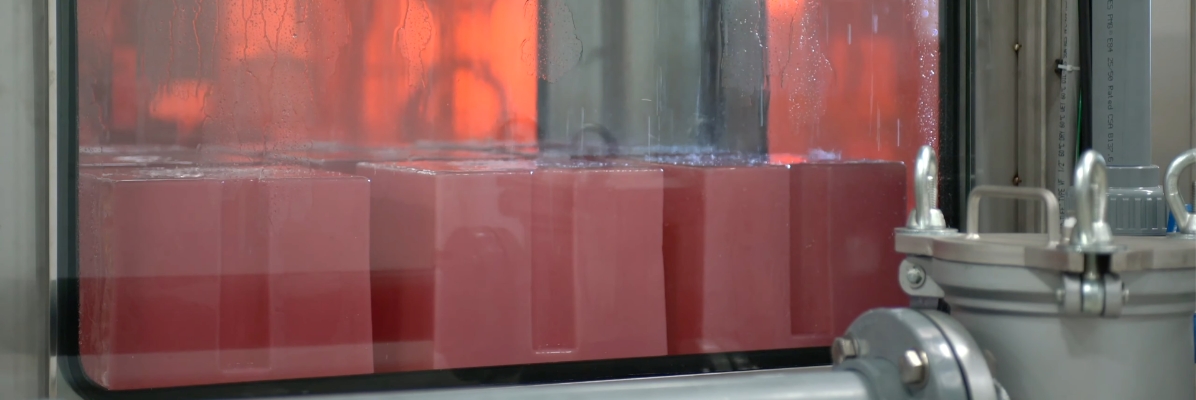

4. Sanitizing

The sanitization stage is a critical step of killing bacteria that can cause health and safety concerns. The tote washing system uses water heated to 180 degrees or chemicals to sanitize items and can be constructed to fit the exact specifications for the customer’s application. Sanitizing is required for numerous products including components for food processing applications, medical waste return bins, and warehouse and distribution center totes.

5. Unloading

Much like loading, this process can be automated or performed by hand. Totes are removed from the end of the conveyor belt and stacked conveniently for future use. Proper safety measures should be taken for metal washer bins that have experienced high levels of heat.

Get Custom Tote Cleaning Equipment From Niagara Systems

Niagara Systems is a global leader in the design and manufacture of tote washer machines and custom industrial parts washers. Customers rely on us for high-quality industrial tote washers that meet all of their requirements. Our advanced cleaning technology has been developed over nearly a century to provide you with state-of-the-art automated cleaning solutions. Contact Niagara Systems today to learn more about our tote cleaning equipment and custom industrial washing machines.