- Keeping it clean since 1934!

- (440) 259-2500

- [email protected]

Industrial Bottle Washer Buying Guide

January 26, 2022

Guide To Industrial Parts Washer Types

June 10, 2022

The Differences Between Parts Washing and Sanitizing

Parts washing is necessary for a wide range of components in numerous industries. It prepares parts for the next step in manufacturing or distribution. Sanitizing is also required for many items. But what’s the difference between washing and sanitizing? And what sorts of parts washing machines are available? Let’s take a look and find out.

Parts Washing Fundamentals

There are several essential steps to parts washing, starting with loading the components into the parts washing machine. Loading can be completed manually or via an automated system. The parts then undergo one or more stages of washing and rinsing utilizing various pressures of spray to remove contaminants like debris or oil. Chemicals are typically introduced in the wash stage(s) to remove the contaminant, while the rinse stage(s) may differ by utilizing recirculated water, fresh water or DI/RO water to remove the wash chemical. Removing the wash chemical is important if drying or applying a rust preventative is a process requirement. All wash and rinse sections can be heated if necessary. The next step is drying. This can take place with high pressure air-knives or by using heated low-pressure air – or a combination of the two. The last step in parts washing is to move the parts on to the next station or unload them, either manually or automatically.

Types of Parts Washing Machines

There’s a broad array of parts washing machines, each suited for a specific end use. This kind of equipment can be categorized in several different ways. One approach is to identify washers by application, such as:

Parts washing machines also can be categorized by type:

Cabinet washers offer a small footprint and are well suited for low volumes of products such as laboratory bottles and glassware, aluminum cylinders, various automotive parts, engine blocks, remanufactured parts, production tooling and fuel injectors.

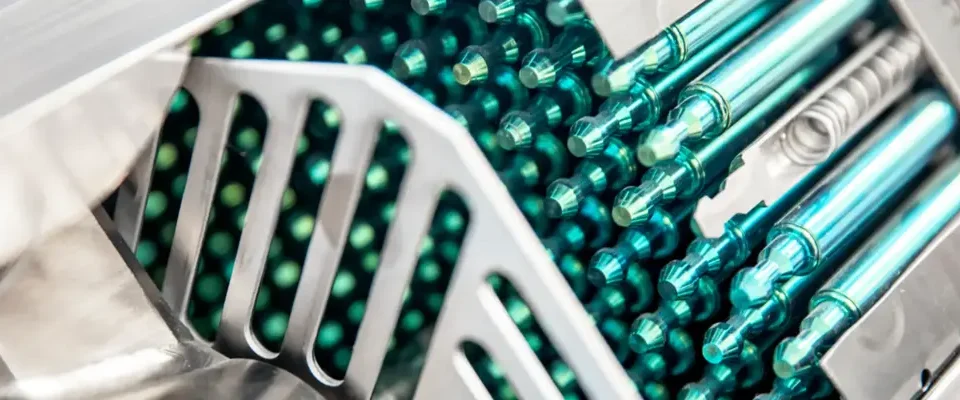

Carousel parts washing machines are ideal for medium- to high-volume applications in the food processing, pharmaceutical, laboratory and automotive parts manufacturing industries.

Tunnel washers are best suited for medium-volume applications, especially dunnage and automotive parts.

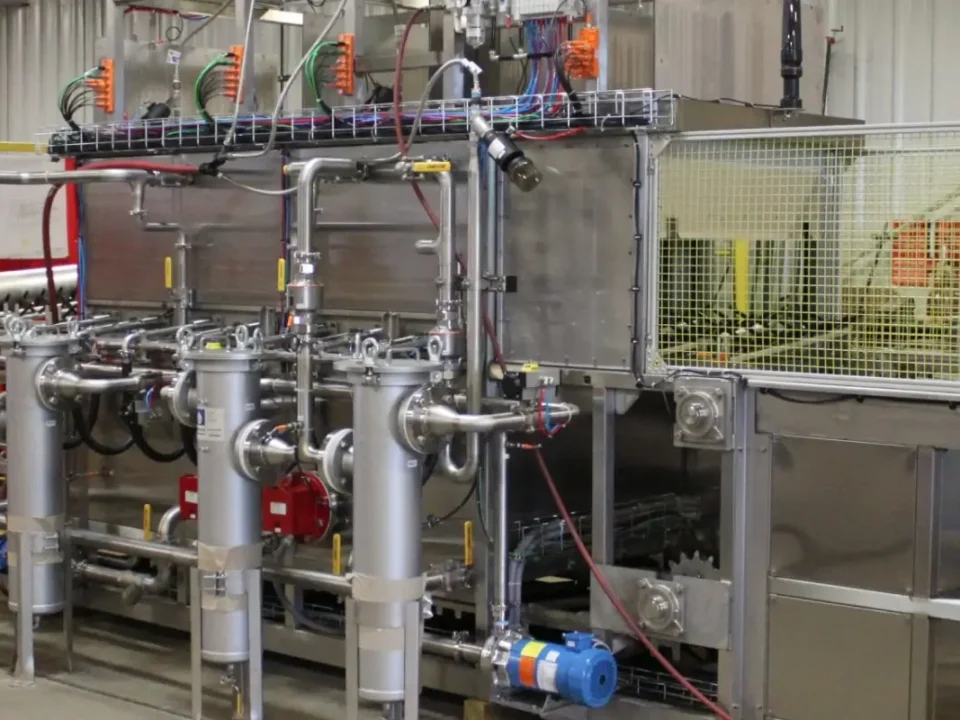

Niagara Systems specializes in all three types of parts washing machines. We also offer custom washers engineered and designed for your exact application. All of our washers offer outstanding features like:

- Stainless steel components

- PLC controls

- User-friendly HMI

- Insulation to reduce heat loss and noise

Parts Washing vs. Sanitizing

While parts washing is geared toward removing debris and residue, sanitizing goes a step further. Sanitization strips away proteins and bacteria that can cause harm. Niagara Systems offers special sanitation stations that can be added to a parts washing machine to provide this critical step.

We engineer and build stations that can use water heated to 180 degrees or chemicals to sanitize items. We design each station to meet the customer’s sanitation needs, as verified by ATP swab tests. We construct our sanitation stations to fit the exact specifications for your application, such as full, passivated welds on units used for food processing. Our sanitizers also utilize cascading tanks to keep recirculated tanks fresher and minimize water consumption.

Sanitizing is required for numerous products, including:

- Components for food processing applications

- Medical waste return bins

- Warehouse and distribution center totes

Trust Niagara Systems for Your Parts Washing Machines

We have over 80 years of experience designing, engineering and building parts washing machines for the most demanding applications, including components with small, deep passages. You can rely on us for the parts washer that will meet your requirements. Request a quote or contact us today to take advantage of our expertise.