- Keeping it clean since 1934!

- (440) 259-2500

- [email protected]

Lab Dishwashers & Drying Systems

January 16, 2023

Manual vs. Automatic Pallet Washing: Why You Should Upgrade to an Industrial Pallet Washer

April 24, 2023

The Basics of Ultrasonic Parts Washers and Cleaning Systems

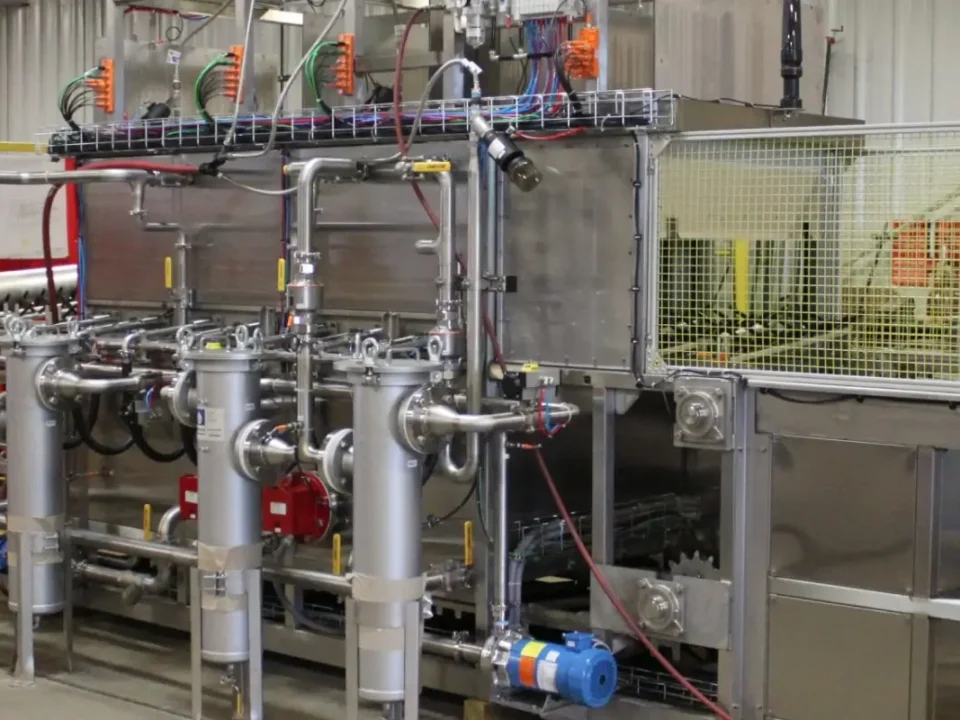

Industrial ultrasonic cleaners are an essential tool for efficient, effective cleaning of manufacturing parts and components. Using ultrasonic waves, these machines can clean various parts and tools. In this article, we’ll cover the basics of automated ultrasonic cleaning systems, their advantages and what to look for when buying your own.

How Industrial Ultrasonic Cleaners Work

Ultrasonic cleaners use high-frequency sound waves to agitate a cleaning solution and remove dirt, dust and grime from various surfaces. An ultrasonic washer consists of:

- A tank or bath filled with cleaning solution

- Energy converter

- Transducer

- Generator

Using an energy converter, an ultrasonic wash system transforms electricity into high-frequency sound waves. The waves are sent into the tank of cleaning solution via the transducer. The generator controls the frequency of the sound waves and the intensity of the cleaning process.

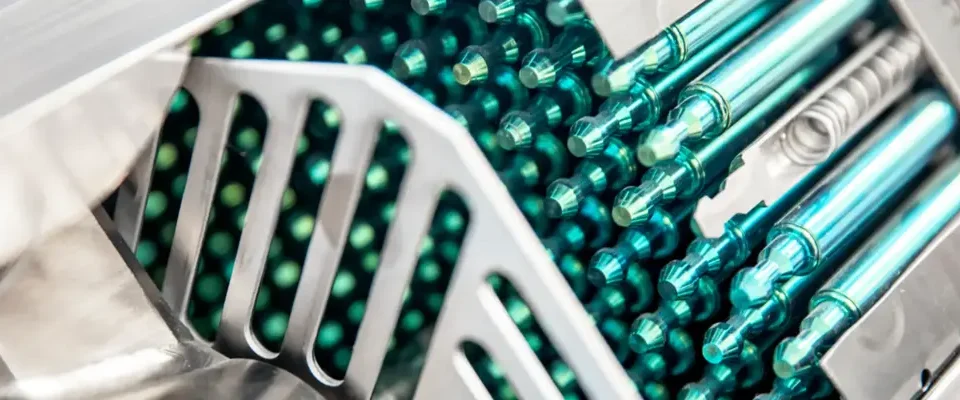

During the ultrasonic wash cycle, the sound waves create millions of tiny microscopic bubbles in the cleaning solution. These bubbles rapidly expand and collapse, producing a powerful scrubbing action that breaks down dirt and grime on the surface. After the ultrasonic wash cycle is complete, the dirt and grime are removed from the surface and the ultrasonic washer is drained.

Applications for Industrial Ultrasonic Washers

Industrial ultrasonic washers are widely used for various applications. Depending on your needs, the size of an ultrasonic cleaner can vary greatly.

Industrial washers for laboratories can be as small as a microwave. These machines are typically used to clean beakers, tools and other testing equipment. Because laboratories utilize caustic and dangerous chemicals, an ultrasonic cleaner is ideal for safe cleaning.

Large-capacity ultrasonic cleaners are often used in industrial environments. These units hold more than 1,500 gallons and simultaneously clean hundreds of small parts. Some of the industries that use ultrasonic cleaners:

- Automotive

- Medical

- Electronics

- Oil and Gas

- Manufacturing

- Food Processing

Benefits of Using Ultrasonic Washers

The benefits of using ultrasonic parts washers are numerous and can have a significant impact on the cleaning process. Here are some of the advantages of using ultrasonic parts washers, including improved cleaning performance, faster cleaning times, reduced need for manual labor, longer equipment lifespan and greater safety.

1. Improved Cleaning Performance

Because of the cavitation process, an ultrasonic cleaner can provide a deeper, more thorough cleaning than other methods. Cavitation bubbles reach into every crevice of the object being cleaned, including those that are difficult or impossible to reach with traditional cleaning systems.

2. Faster Cleaning Times

Ultrasonic washers are highly efficient cleaning systems. With the ability to remove contaminants from multiple parts simultaneously, ultrasonic cleaners are also highly efficient due to the cavitation process.

3. Reduced Labor

Because the cleaning process is automated and requires minimal user input, overall labor is reduced significantly. Unlike traditional cleaning methods, an ultrasonic washer does not require manual scrubbing, soaking or spraying.

4. Extended Equipment Lifetime

Thoroughly cleaning your tools and equipment can remove hazardous materials and other contaminants. This can remove potential risks and points of failure and extend the life of your equipment.

5. Higher Safety Standards

Ultrasonic cleaning solutions are often less toxic and more environmentally friendly than other options. Likewise, ultrasonic washers reduce the likelihood of injury caused by part cleaning by reducing human interaction during the cleaning process.

What to Consider When Buying a Large-Capacity Ultrasonic Cleaner

The requirements of your business or institution can vary greatly depending on your cleaning needs. Here is a list of what to look for when buying a large ultrasonic cleaner.

1. Size and Capacity

Determine the size of the items you need to clean and ensure that the ultrasonic cleaner can accommodate the largest item you need to clean. Additionally, consider the tank capacity, as larger tanks can clean more items in a single cycle and reduce cleaning time.

2. Frequency and Power

The frequency and power of the ultrasonic waves can affect the cleaning performance and efficiency of the machine. Higher frequencies and power output can provide more efficient cleaning performance and reduce cleaning time.

3. Cleaning Solutions

Ensure that the cleaning solution you will use is compatible with your industrial ultrasonic cleaner. Additionally, consider the temperature and pH requirements of the cleaning solution and confirm that the ultrasonic cleaner can accommodate these requirements.

4. Control Options

The level of control options available on the ultrasonic cleaner — such as temperature control, timer settings and power output control — are highly valuable if you need a wide operating window for different parts and equipment. Ensure that the control options are user-friendly and can be easily adjusted to suit your cleaning needs.

5. Material and Build Quality

Consider the material and build quality of the ultrasonic cleaner, as this can affect the durability and lifespan of the machine. Look for a machine made from high-quality materials and with a sturdy construction that can withstand frequent use.

6. Accessories and Features

Any additional features or accessories that may be necessary for your cleaning needs, such as baskets, lids or drainage options. Look for features such as automatic shut-off or overheat protection, which can increase the safety and efficiency of your industrial ultrasonic cleaner.

7. Budget

Determine your budget and look for a machine that meets your cleaning needs while also fitting within your budget. Consider the long-term costs of maintenance and repair along with the upfront cost of the machine.

Contact Niagara Systems For Custom Ultrasonic Wash Systems

Niagara Systems is a global leader in industrial washers and automated cleaning systems. Our new lineup of industrial ultrasonic cleaners offers one of the most complete inventories of automated cleaning equipment. Choose one of our units to experience the difference that a high-quality ultrasonic washer can provide. Contact us for available customization options on our automated ultrasonic cleaning systems.