- Keeping it clean since 1934!

- (440) 259-2500

- [email protected]

Industrial Parts Washer and Cleaning Systems 101: The Basics of Industrial Parts Washing

August 18, 2021

Relative Humidity vs. Temperature

November 4, 2021

Millipore Testing: A Guide for Measuring and Verifying Industrial Part Cleanliness

How well does your industrial parts washer work? Part cleanliness is an important part of production and manufacturing processes. Industrial parts washers serve as vital tools to reduce part degradation and sanitize tools and machines. In this guide, we discuss Millipore testing, how it is used, and what impacts it has on various industries to ensure sanitation and purity.

What Is Millipore Testing?

A method of verifying part cleanliness, Millipore water testing measures the presence of solid particles and other non-soluble contaminants on machine parts. In most cases, the results of Millipore testing are expressed either by the size and number of particles collected or by gravimetric analysis following extraction. Millipore test equipment gathers particles that are suspended in a liquid and applied to a filter which is then dried to allow for weighing and further analysis. Millipore cleanliness testing is an integral part of several industries, including automotive and pharmaceuticals.

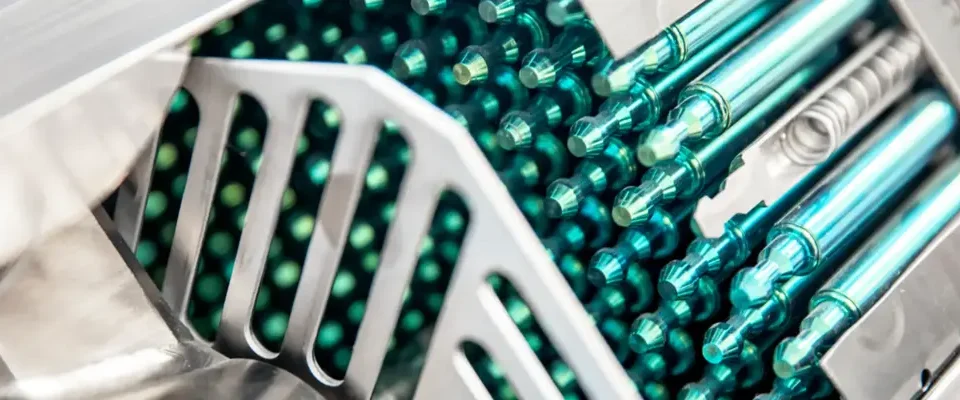

The automotive industry utilizes Millipore testing to validate parts cleaning. Particle contamination in fluid systems and other components can lead to inefficiencies and result in safety concerns. Too much particle contamination in fuel and oil lines can have adverse effects on engine performance while leading to greater engine wear over a vehicle’s lifetime. To counteract this, manufacturers use automotive parts washing to remove contaminants and Millipore cleanliness testing equipment to establish higher standards of quality.

Likewise, pharmaceutical companies have to be aware of potential contaminants and particle buildup due to regulations and safety standards, making Millipore testing a crucial function. Among the primary concerns is the risk of cross-contamination between batches of different medications or products. For this reason, manufacturers need pharmaceutical-grade parts washers for their machines and tools to thoroughly clean and sanitize them. Subsequently, they can use Millipore testing for contamination monitoring.

How To Complete A Millipore Water Test

Millipore water testing kits come with the necessary tools and instruments you need to perform a particle examination. Millipore testing involves several steps. After setting up your Millipore test kit, you will want to normalize results across different test components by removing extraneous variables from your analysis. First, thoroughly rinse and dry a nonporous tray or pan that will be used as the initial particle collection apparatus. Make sure that the Millipore test equipment has been rinsed and cleaned as well. Next, prepare the Millipore pad for collection by cleaning and drying it. After it is dry, placing the pads into a desiccator will normalize humidity levels to ensure accurate results when testing different parts. After drying, weigh the Millipore pad to get a baseline figure.

Following these preparation steps, flush the part or tool you are testing over the pan or tray for particle collection. Thoroughly rinse all relevant surfaces of the part in order to collect as much particle contamination as possible. After the part has been flushed, pour the collected contaminants onto the Millipore testing pad for further analysis. Rinse the collection pan to make sure all potential particles have been gathered.

Lastly, dry the Millipore testing pad again to remove all water residue. Place it in the desiccator to normalize humidity levels and then weigh the pad a second time to note the difference. You will then prepare the pad on a slide for further visual analysis using a particle scanning microscope or similar device. Once you are done with the testing procedure, you can utilize laboratory glassware dishwashers to clean components of your Millipore test equipment.

How Can a Millipore Water Testing Kit Help You Gain Insights?

Millipore testing is an essential function for both quality control in manufacturing as well as validation of cleanliness achieved by parts washers and other processes. Contaminant buildup on machine parts and tools can lead to more rapid degradation and eventual deterioration. Utilizing industrial parts washers to clean your machine parts ensures the removal of particulate matter buildup. A Millipore water testing kit can be used with a control group to gain a better understanding of how much benefit you receive from a parts washer by analyzing the number of particles present on tools and parts before and after cleaning. These results can then be used to optimize your part washing process for both frequency and magnitude.

The Benefits Of Millipore Cleanliness Testing

- Validate cleanliness results of a specific cleaning or manufacturing process

- Gather data on particle accumulation and part degradation

- Ensure production and safety standards regarding product contamination

- Optimize cleaning and production processes for more efficient manufacturing

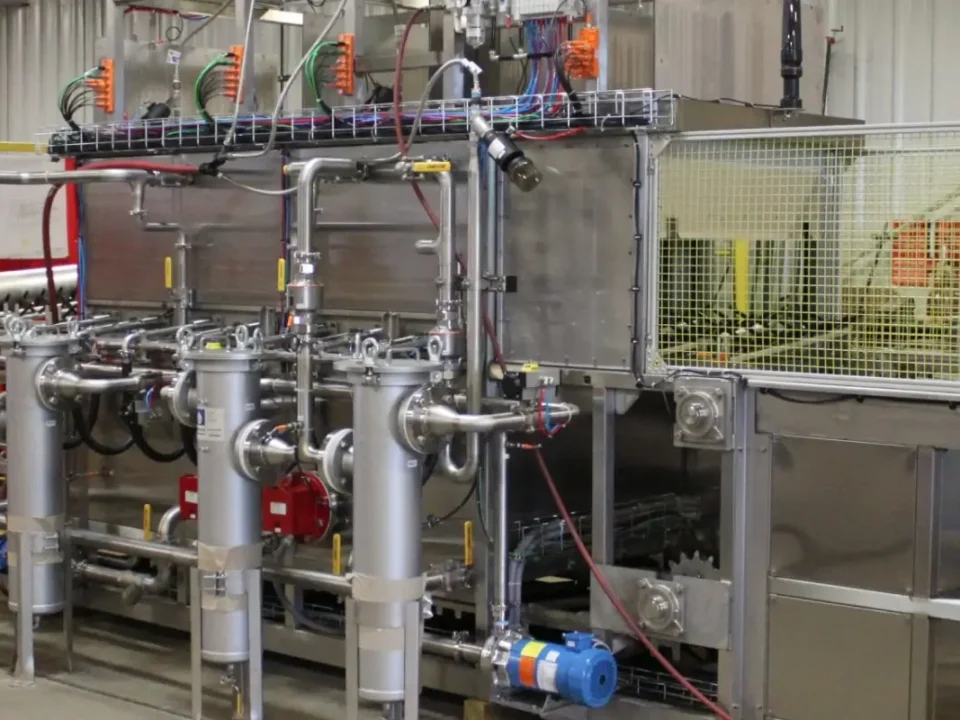

Get a Niagara Systems Parts Washers For Your Application

Niagara Systems has been setting the standard since 1934 on industrial parts washers. Millipore testing is useful for measuring and verifying part cleanliness after your initial wash cycle. Niagara Systems is an industry leader in part cleanliness by providing standardized and custom solutions for your parts washing needs. View our gallery and see firsthand what Niagara Systems can do for you.