- Keeping it clean since 1934!

- (440) 259-2500

- [email protected]

Millipore Testing: A Guide for Measuring and Verifying Industrial Part Cleanliness

September 15, 2021

Conveyor Belt Washer Selection Guide

November 4, 2021

Relative Humidity vs. Temperature

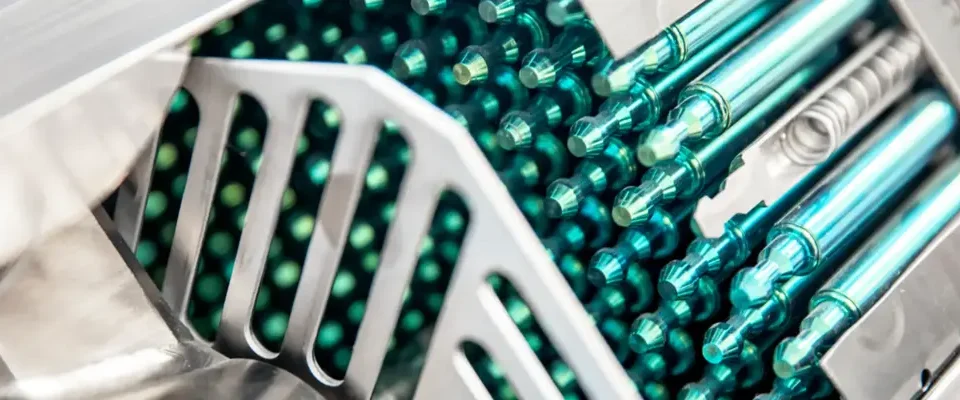

When food processors need a cleaning solution for their parts, they look for commercial washing equipment that is designed to be fast, durable, reliable and, above all, sanitary. This allows food processors to cycle through their parts so they can keep the food moving from the line to the customers.

One of the often overlooked components of the wash cycle is the drying process. In order to keep production moving, parts need to dry quickly and efficiently. In order to do so, parts washers need to take both relative humidity and temperature into account for their drying process. But what is relative humidity? And how does it impact the drying process of your food processing commercial washing equipment? Today we’ll take a look at those questions, compare relative humidity vs. temperature, and discuss how you can keep your food processing parts clean with minimal downtime.

What Is Relative Humidity?

Relative humidity expresses the relation of water vapor present in a volume of air. Usually expressed as a percent, relative humidity is a ratio of the present state of absolute humidity compared to the maximum possible humidity given the same air temperature. For instance, if one kilogram of air has a temperature of 50 degrees Fahrenheit, it is capable of holding roughly eight grams of water vapor before hitting its saturation point. If that kilogram of air currently has four grams of water vapor in it, then it has a relative humidity of 50%.

How Is Relative Humidity Affected By Temperature?

Put simply, the hotter a room is, the more water vapor it is capable of holding. Colder air can hold much less water vapor by volume than a warm room of the same size. Temperature and relative humidity are intrinsically linked; as one goes up, so does the other. Increasing temperature by a few degrees has an exponential impact on the amount of water vapor that volume of air is capable of holding before becoming completely saturated.

Why Does Relative Humidity Matter In Commercial Washing?

For commercial washing, a high temperature with a low relative humidity allows the transfer of more water vapor from your parts, dishes and utensils to the surrounding air, speeding up the drying process. Therefore, relative humidity in parts washing should be considered as a factor when measuring the overall efficiency of a cleaning system. The temperature at which a component is capable of operating during its drying cycle will greatly impact the speed by which parts can be dried.

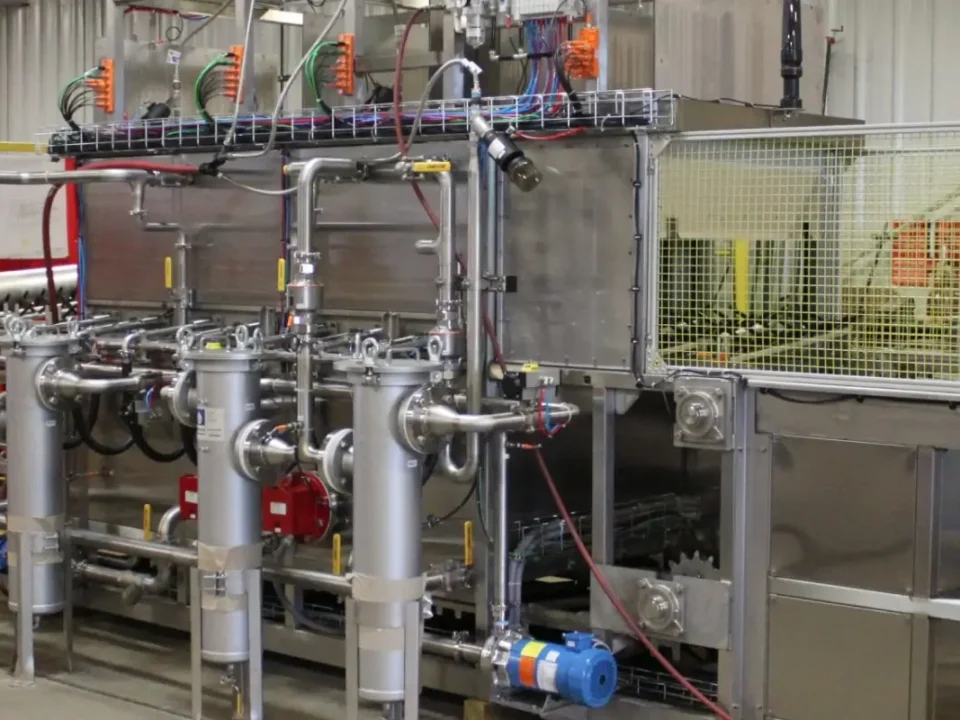

Commercial washing equipment for food processing takes these factors into account. Tunnel washing systems such as the Niagara Series 200 use a combination of heat and high-velocity air to rapidly accelerate the drying process. Capable of moving 1,600 cubic feet of air per minute at temperatures ranging from 140 to 220 degrees, the tunnel washer combines rapid air movement with higher temps to quickly and efficiently dry your parts.

Why Is This Important For Food Processing?

In food processing, commercial washing equipment has to meet high standards of cleanliness and sanitation. For tooling and other equipment used during processing, regular cleaning is required to maintain production standards. A cleaning system for food processing has to be able to handle many variables while accommodating different types of equipment used throughout the industry.

Trust Food Grade Washers From Niagara Systems

Commercial washing equipment from Niagara Systems has been meeting the needs of the food processing industry for 85 years. Our complete parts washing systems are customizable for your specific processes and are designed to serve in clean-room and food-grade environments. Contact us today to learn how Niagara Systems can improve your parts washing operation.