Mission-ready cleaning solutions engineered for the defense sector.

Niagara Systems' military parts washing solutions ensure your mission-critical components are cleaned to exacting MIL-SPEC and MIL-STD requirements. In military operations, contaminants can mean the difference between success and failure. That's why our systems are engineered to remove every trace of grease, debris, and residue from parts of all sizes.

Do you need a niche or highly specialized design? Our team is ready to collaborate with you to custom-engineer a solution that fits your operation. Tell us about your process and application requirements today.

Get in Touch »Precision Cleaning for Critical Military Components

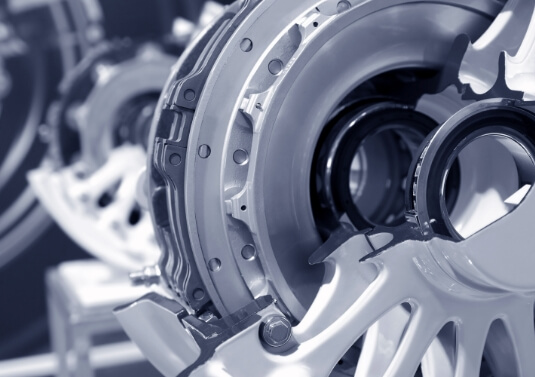

Niagara Systems’ military parts washing systems are built to tackle the toughest grime on the most mission-critical parts. From grease-caked jet engines to the intricate nooks and crannies of missile guidance systems, our military washers ensure every component is inspection-ready. In the defense sector, even a microscopic particle can compromise performance—our systems are here to guarantee that doesn’t happen.

Our Series 100, 200, 300, & SonixClean military washing systems can clean:

- Engine Components: Clean engine parts such as cylinder heads, crankshafts, connecting rods, pistons, and others of grease, carbon deposits, and oil buildup.

- Aircraft Parts: Leave zero residue to interfere with aerodynamics or mechanical integrity on components like hydraulic assemblies, turbine blades, landing gear components, and more.

- Heavy Weaponry: Keep breech mechanisms, barrel assemblies, and other weapons components free of fouling, carbon buildup, and corrosive residues.

- Missile and Guidance System Components: Eliminate contaminants from sensitive electronics and structural parts without damaging their delicate materials or compounds.

- Vehicle Chassis and Frames: Strip away dirt, mud, debris, sand, and corrosion to keep military vehicles operational and mission-ready.

Versatile Configurations for Comprehensive Military Parts Washing

Military equipment comes in all shapes and sizes, each with unique cleaning challenges. That’s why we offer military parts washing systems in a variety of customizable configurations, each meeting stringent MIL-SPEC and MIL-STD requirements.

Series 100 Model L210 Cabinet-Style Washer

The Series 100 Model L210 Cabinet-Style Washer is purpose-built for batch-style washing and an exceptional choice for cleaning military components with intricate geometries.

Its rotating basket design ensures that every angle of a part, no matter how complex, is thoroughly cleaned and free of contaminants. With a powerful high-capacity pump and precision-engineered spray nozzles, the L210 consistently penetrates hard-to-reach areas, such as internal channels and tight crevices.

Series 200 Model MT23 Tunnel-Style Washer

The Series 200 Model MT23 Tunnel-Style Washer is the ideal solution for operations requiring high-production military parts washing for various-sized components.

Its modular conveyor system moves parts efficiently through multi-stage cleaning processes, ensuring even large or irregularly shaped components receive comprehensive treatment. With available sections for prewash, wash, rinse, and blow-off, the MT23 streamlines operations by handling all stages of cleaning in one continuous process.

Let’s Build Your Mission-Ready Washing Solution

When cleaning critical military components to spec, there’s no room for compromise. At Niagara Systems, we bring decades of expertise in designing and manufacturing custom military parts washing systems with unbeatable performance and reliability.

Get in touch today. Let’s discuss the specifics of your operation, and work together to create a defense industry part cleaning system that meets your mission’s demands.

Frequently Asked Questions: Defense Industry Parts Cleaning Systems

If you have questions about our systems or would like to know more about defense industry parts cleaning, check out our helpful FAQ for more insights.

What contaminants can military parts washing systems remove?

Military parts washing systems are designed to handle a variety of contaminants, including oil, grease, carbon deposits, dirt, corrosion, scale, and residual chemicals. Ultrasonic systems can even remove microscopic particles that could interfere with sensitive equipment or precision components.

Can military cleaning systems integrate with existing workflows?

Yes, Niagara Systems designs washers that can easily integrate into existing production lines and automated systems. Features like adjustable belt speeds, modular sections, and load/unload options ensure compatibility with upstream and downstream processes.

Are military cleaning systems energy-efficient?

Our military washers incorporate energy-saving features such as high-efficiency pumps, insulated tanks, and programmable cycles to minimize resource use while maximizing cleaning performance. Options for electric, gas, or steam-powered heated tanks also provide flexibility based on operational needs.