- Keeping it clean since 1934!

- (440) 259-2500

- [email protected]

6 Benefits of Using an Industrial Bottle Washing Machine

October 6, 2022

How To Choose the Best Industrial Parts Washer Based on Application

November 29, 2022

How An Industrial Crate Washer Machine Can Improve Your Facility’s Efficiency

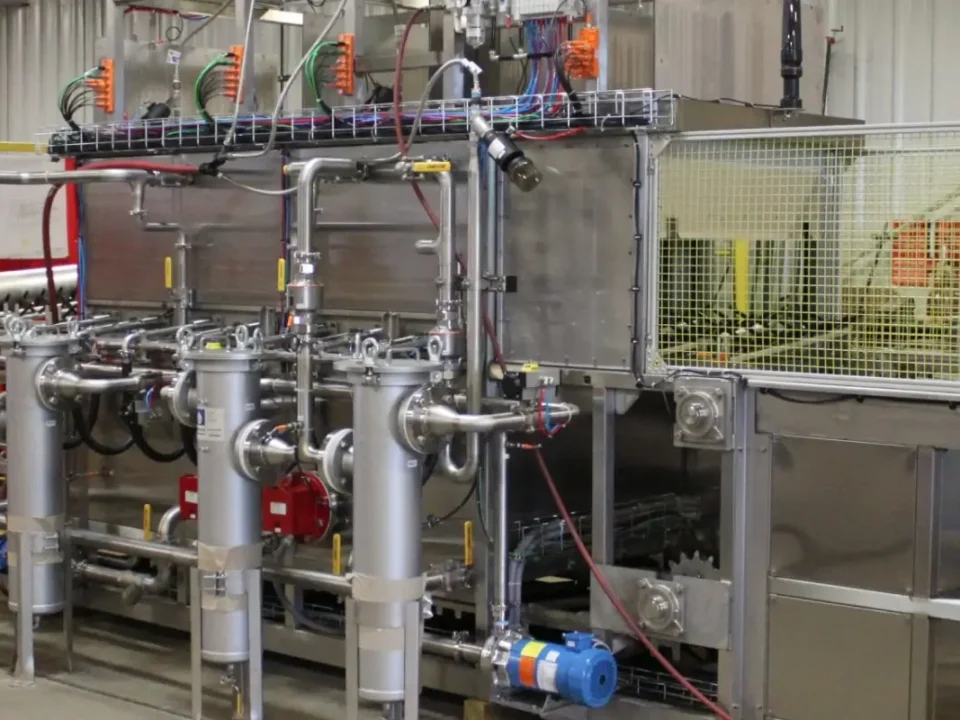

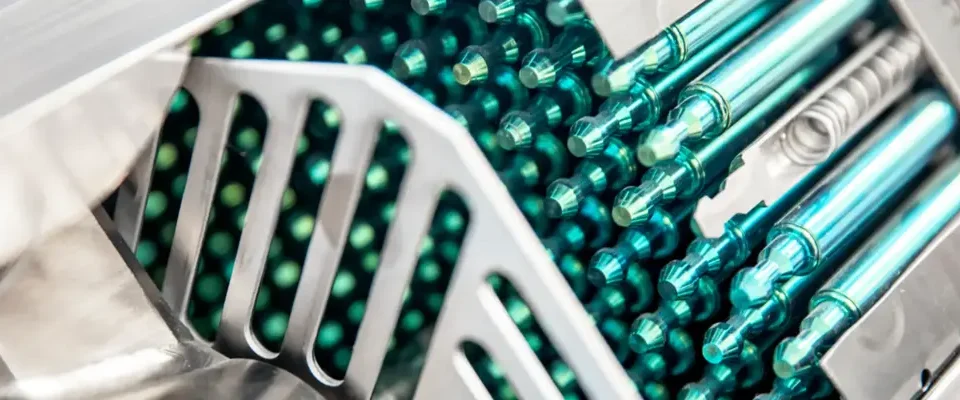

A crate washer is an industrial washing system that can effectively remove stains on a crate’s surface to achieve better cleaning results. Many factories, facilities and farms need to use crates to store or transport their products – leaving them stained and unwashed is a health hazard. To ensure your facility’s products are hygienic, uncontaminated and in accordance with Hazard Analysis Critical Control Point (HACCP) guidelines, investing in an industrial crate washer machine is a must. But that’s not the only way a crate washing system can improve your facility. This article will look at a few ways an industrial crate washer can take your facility’s efficiency to the next level.

The Insulation of Exterior Walls

Another way an industrial crate washer can increase efficiency throughout an operation is by optionally adding insulated exterior walls. While not a standard feature, insulated exterior walls are incredibly beneficial in the long run. With insulated walls, heat won’t be able to escape as easily during the crate washing process, providing a reasonable reduction in energy losses. Additionally, this feature allows for even more savings on energy costs.

The Frequency Regulation

During the crate washing process, crates are transported using a chain conveyor throughout the industrial washing system. Another optional component you can add to increase facility efficiency is a frequency regulator, which allows operations to adjust the speed by which the conveyor moves. How can this increase efficiency? It’s simple. When crates are slightly soiled, the operator can increase the speed, so less energy and water are needed for each crate. When an operator needs the maximum amount of cleaning power, the conveyor can be slowed down.

The Hygienic Design

One of the most essential aspects of crate washing is hygiene. As mentioned, the entire reason for washing crates is to ensure your facility’s products are hygienic. However, cleaning crates by hand is far from the most hygienic method. An industrial crate washing system comes standard with the most hygienic design possible to ensure crates, operators, and the machine itself are always free from cross-contamination.

Manufactured with hygienic stainless steel and a sloping design so that no water remains, facilities can clean industrial washing systems quickly and efficiently. Less water, energy and sanitation cleaning agent are needed to achieve the same results as hand washing crates, increasing efficiency and saving countless dollars on cleaning costs.

Contact Niagra Systems for Your Industrial Crate Washer Machine Today

Whether you work in the healthcare, pharmaceutical, automotive, food and beverage or chemical industry, an industrial crate washer machine can help improve your efficiency. Niagara Systems has been designing and manufacturing industrial washing systems for years and would love to bring our ideas to your operation. There’s a reason we’ve been industry leaders for more than 50 years – no matter how many crates you wash daily, we can design the perfect crate washer for you. Request a quote today.