- Keeping it clean since 1934!

- (440) 259-2500

- [email protected]

How An Industrial Crate Washer Machine Can Improve Your Facility’s Efficiency

November 4, 2022

Lab Dishwashers & Drying Systems

January 16, 2023

How To Choose the Best Industrial Parts Washer Based on Application

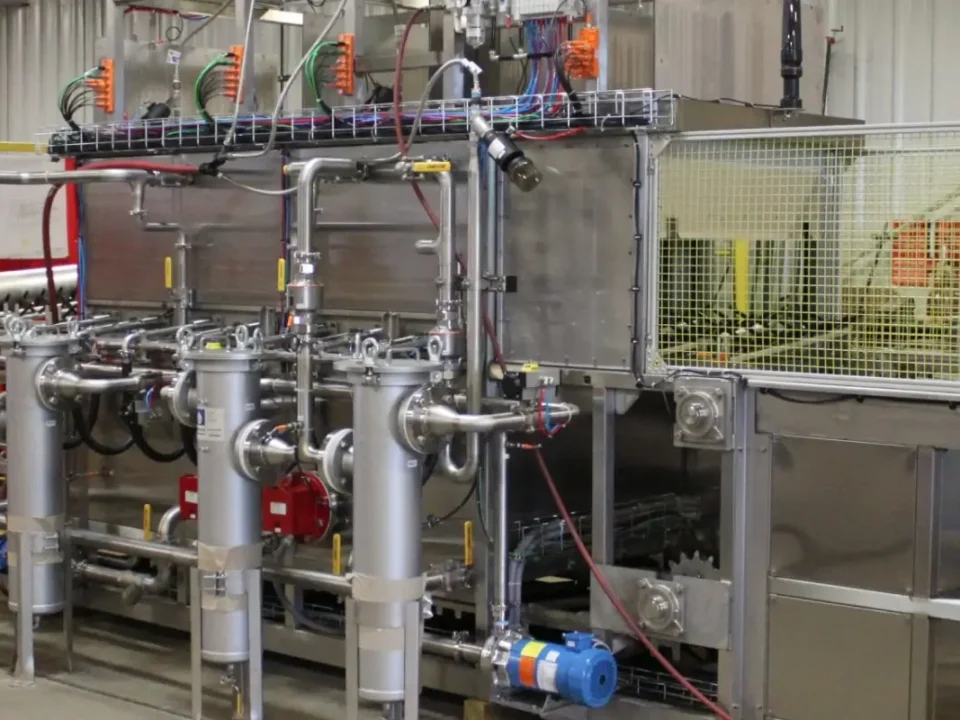

If you’re looking for an industrial parts washer, narrow down your options by defining your process requirements. Parts washers are complex pieces of machinery – choosing the wrong one can cause serious issues within your operation. An ineffective industrial parts washer can cause quality control issues, production bottlenecks, maintenance problems and safety risks, while also draining labor resources. Thankfully, the experts at Niagara Systems are here to help. To select the best industrial parts washer for your application, consider the following seven questions. Doing so will help you improve your cleaning process and ensure that your new automatic parts washer brings value to your operation.

1. What Types of Parts Need To Be Cleaned?

Different industrial parts washers perform specific operations more effectively for different industries. Whether you work in the automotive industry or deal with pharmaceutical equipment, there are cleaning systems best suited for your parts.

That’s why knowing what type of parts you have to clean is so crucial. If the parts are small and not complex, like washers and nuts, you may be more interested in a drum or immersion washer. However, large parts, such as automotive engine blocks and dunnage used to pack parts, will require an industrial parts washer using a carousel or tunnel cleaning system.

2. What Are Your Parts Made Of?

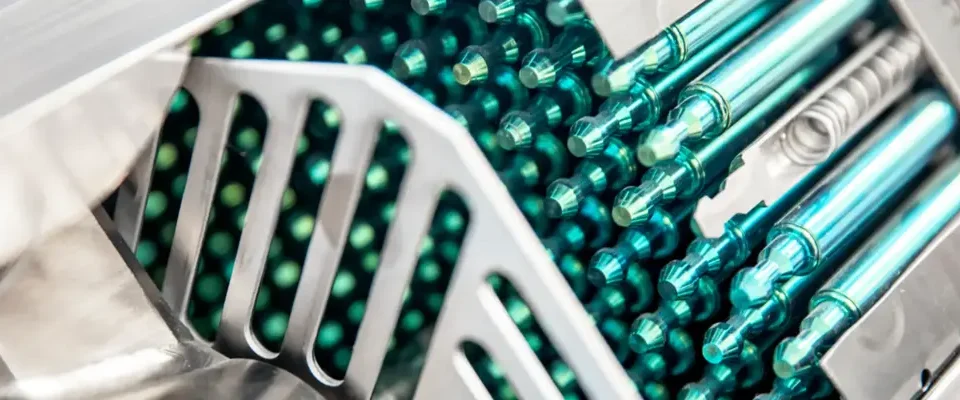

The cleaning process for an industrial parts washer heavily depends on the type of material you’re cleaning. Glass, plastic, stainless steel, cast iron, aluminum, brass, copper and other parts will require different cleaning systems and processes to ensure proper sanitization.

3. What Type of Contaminants Are You Cleaning?

Industrial parts washers are used to remove various forms of contaminants from parts. Knowing what contaminants you’re cleaning is essential for determining what cleaning system to choose. For example, oil, grease, carbon, varnish, paint and volatile organic compounds (VOCs) will require different power density levels, pressure, flow and heat to remove.

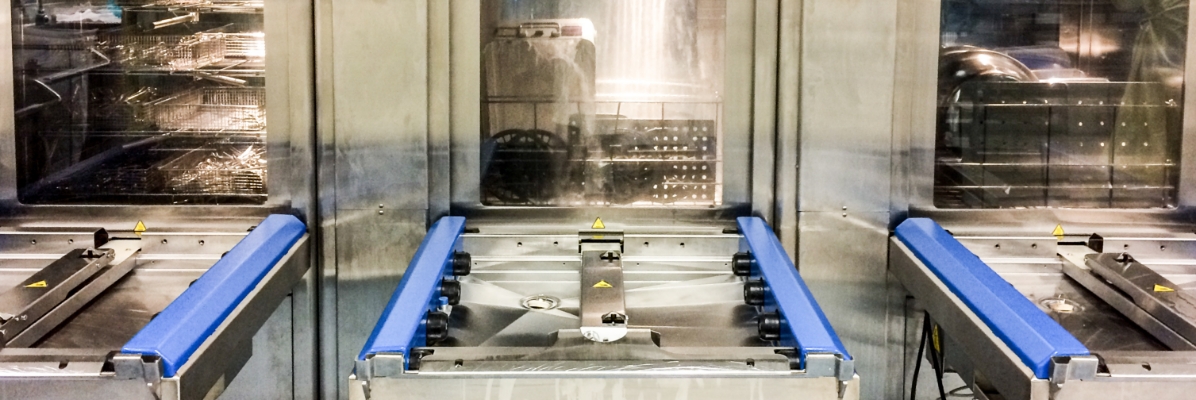

If you’re struggling to visualize how an industrial parts washer works, see one of our tunnel washers in action in the short video above.

4. What Would You Like Your Production Rate To Be?

The volume of parts you plan to clean per day will help you determine the power output your industrial parts washer must deliver. By knowing your production rate, you can select the cycle time, load capacity and number of loads per day. Operations with high volume requirements will likely require automated parts washers with high levels of automation and interface integration. On the other hand, operations that only clean a few parts per day may find more value in an operator-run industrial parts washer.

5. What Is Your Parts Handling Process?

Once you determine your load capacity and production requirements, you must figure out how your parts will be loaded into and removed from your industrial parts washer. Some operations may have adequate labor and light parts that can be loaded and unloaded manually. In contrast, others may call for an automatic conveyor system to keep up with their production cycles.

6. Are There Critical Areas of Cleaning and Drying You Need To Address?

Another essential part of choosing an industrial parts washer is determining whether or not certain areas of your parts require a more critical cleaning and drying process. Some parts may require internal cleaning, such as bottles and glassware, while others only require cleaning on external surfaces. Prestrain filter baskets, oscillating spray wash manifolds, dry cycling fans and other features can be added or omitted from an automatic parts washer depending on the application requisites.

7. What Is Your Cleaning Process Objective?

The cleaning process for your unique application mainly depends on whether you have clearly defined cleanliness or drying requirements. Laboratory equipment requires cleaning, disinfection and complete sterilization, while other industries only call for visual cleanliness. How will you measure compliance with those requirements? Standard methods include visual inspection, millipore test, particle count and the white glove test. Your industrial parts washer can be uniquely customized to your exact cleanliness obligations.

Niagara Systems Can Help You Find the Best Industrial Parts Washer for Your Application

Once you’ve answered the questions above, a Niagara Systems expert can help you find the best industrial parts washer and heavy-duty cleaning system for your upcoming projects. With 85 years of industry experience under our belts, there’s no question we can help you find a solution that meets the requirements of your unique application. Request your quote today to get started. If you need assistance answering these questions or want to talk more about our company, feel free to contact us anytime. Our parts washer experts are always here to help.