- Keeping it clean since 1934!

- (440) 259-2500

- [email protected]

Guide To Industrial Parts Washer Types

June 10, 2022

How An Industrial Crate Washer Machine Can Improve Your Facility’s Efficiency

November 4, 2022

6 Benefits of Using an Industrial Bottle Washing Machine

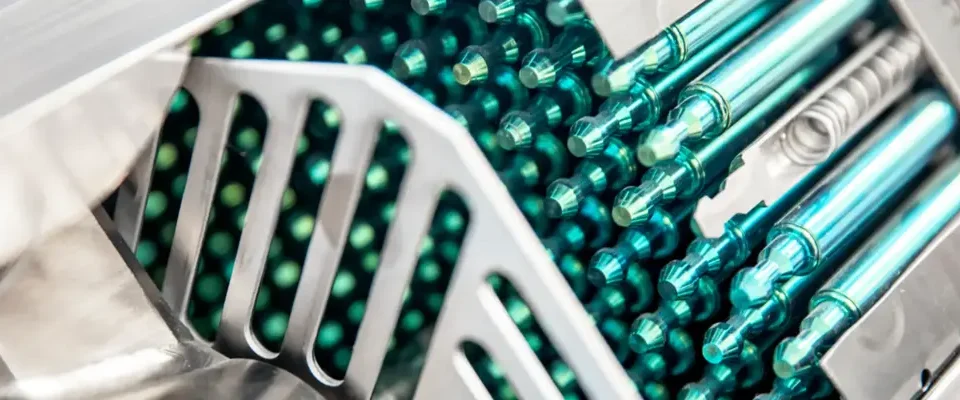

Over the years, the industrial bottle washing machine has become an integral part of many industrial and commercial operations. Breweries, beverage manufacturers, pharmaceutical labs and others rely on the capabilities of bottle cleaning machines to keep their operations as economical and ecologically friendly as possible. With the power to efficiently and quickly wash, bleach and dry glass and PET (polyethylene terephthalate) bottles, bottle washer and sterilizer machines provide tons of benefits to companies hoping to increase their bottom line. Keep reading to learn more about the benefits an industrial bottle washing machine can provide for you.

1. Bottle Washing Machines Are Cost-Effective

Designed with a low bottle discharge unit, automatic or semi-automatic conveyor options and an overall low height, industrial bottle washing machines are ideal for staying environmentally friendly and cost-effective. At Niagara Systems, our industrial bottle washers can wash up to 200 to 750+ bottles per hour with the economical use of recycled water. Additionally, their compact designs enable companies to use them with limited space, giving anyone more room for additional needs.

2. Bottle Sanitizing Machines Have a Wide Range of Applicability

A bottle sanitizing machine isn’t a one-trick pony – these machines can meet the stringent demands and needs of various industries. With an industrial bottle washer, companies can clean and sanitize bottles no matter their size, material, shape and color.

Industrial bottle washing machines can benefit industries of all types, including (but not limited to):

- Refinery Laboratories

- Pharmaceutical Laboratories

- Soda Bottling Plants (For Glass, PET & Aluminum Bottles)

- Electronic Manufacturers

- Breweries & Microbreweries

- Wineries

- & More

Bottle sanitizing machines can even be custom designed and built to suit specific washing and drying needs for smaller, more niche industries.

3. An Industrial Bottle Washer Contributes to Efficient Operations

Before the invention of the industrial bottle washer, industries were forced to wash bottles by soaking them in water to soften the dirt, manually scrub the labels and then sanitize them. This is an extremely time-and energy-consuming process that can put a significant dent in the efficiency of any operation. With an automated bottle washer, employees only need to load the bottles onto the rack and press the start button to achieve the same results.

4. Bottle Washers Are Highly Effective

Let’s face it; bottles are difficult to wash by hand. Not only is the process time-consuming, but their unique shapes also make them a challenge to clean thoroughly. If even a small amount of residue is left over, it could influence how a drink tastes, ruin the structure of future powders and solutions or make the contents go bad well before they should. Bottle washers are the most effective way for any operation to ensure bottles are properly cleaned and sanitized before they are filled. With superior drying and a two-stage filtering system, industrial bottle sanitizing machines ensure effective cleaning and sanitization compliance with food-grade, electronic and pharmaceutical specifications.

5. Bottle Cleaning Machines Are Extremely Durable

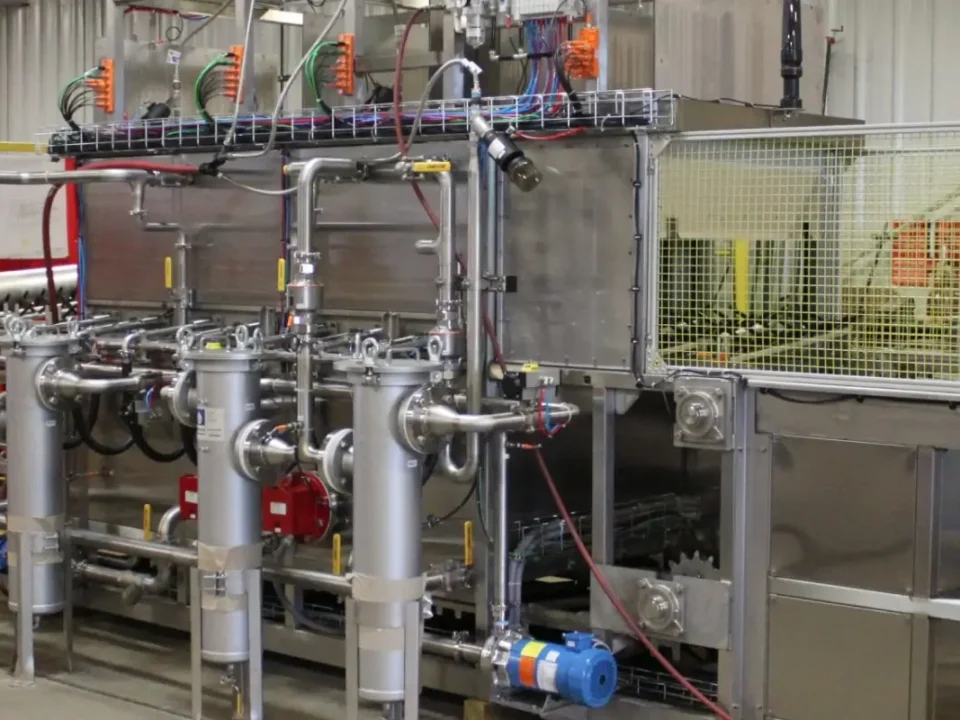

Investing in anything with limited durability will lead to a loss in your bottom line. Thankfully, industrial bottle cleaning machines incorporate stainless steel headers, racks and pumps for a clean, durable and corrosion-resistant machine that can withstand years of use. Additionally, non-stainless steel components are designed with materials impervious to detergents and most industrial and laboratory chemicals. When you order from Niagara Systems, you can even request your bottle cleaning machine to be explosion-proof. Now that’s durability.

6. Bottle Washer and Sterilizer Machines Are Safer For Employees

When employees are required to wash bottles manually, there is a greater chance of accidents occurring. Bottles can be delicate, so breakages happen pretty often, which costs your company money and is dangerous for workers. Bottle washer and sterilizer systems won’t force employees to handle slippery glass bottles coated in soap, which can lower the number of accidents and keep your workers (and your bottom line) safe.

Find the Industrial Bottle Washing Machine to Benefit Your Bottom Line at Niagara Systems

Now that you know the benefits and advantages an industrial bottle washing machine can provide, it’s time to find the perfect one for your operation. Niagara Systems’ specialized bottle washers can fit your exact needs and operational applications, no matter the industry. From beer bottle washers to lab glassware dishwashers, Niagara Systems is committed to improving your operation’s quality, durability, safety and efficiency. Request a quote today.

If you have any questions or need more details about our bottle cleaning machines, feel free to contact us. We’re always happy to help.