- Keeping it clean since 1934!

- (440) 259-2500

- [email protected]

Tunnel Washer Buying Guide

December 7, 2021

The Differences Between Parts Washing and Sanitizing

February 1, 2022

Bottle Washer Buying Guide

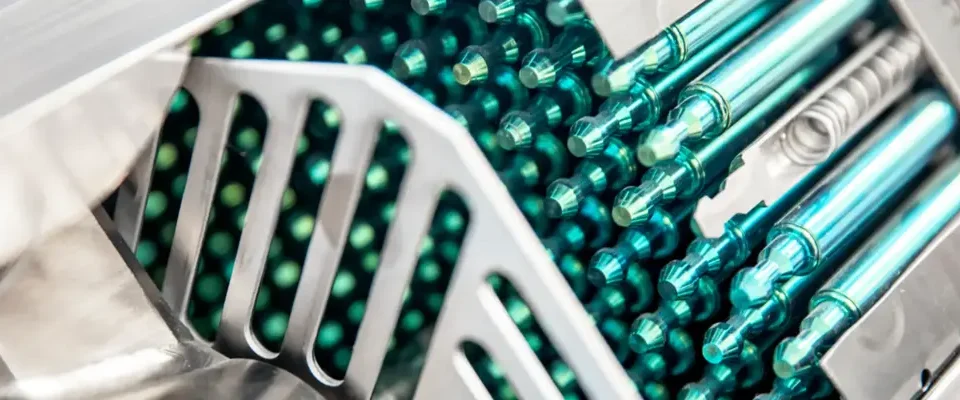

Bottle washers are unique washing machines designed to clean and sanitize everything from beer bottles to lab equipment. The type and size of bottle washing machine you need will depend on several factors. Our guide on commercial bottle washers covers everything you need to know when considering your own washer system.

What Is a Bottle Washer Machine?

While other parts washers are more general in their design in order to accommodate different kinds of parts and materials, bottle washer machines are specially designed to meet certain requirements. They often consist of multiple jets that force chemistry into bottles to effectively clean and sterilize them by contacting all interior and exterior surfaces. The solution is typically heated to meet specific sanitation levels and provide quality assurance. Production lines rely on consistent, thorough cleaning solutions to ensure product safety and hygiene during the bottling process. Research labs and testing facilities require thorough decontamination of their equipment after use. Bottle washing machines provide a critical function for many different industries.

Bottle Washing Machine Applications

“Bottle washer” is a broad term that covers a large range of commercial bottle washing machines. Many different types of bottle washer machines are used in multiple industries and sectors for different purposes. Some of our bottle washer applications include:

- Food and Beverage

- Pharmaceuticals

- Electronics

- Oil and Gas

- Research Labs

- Recycling

- Breweries

- Bottle Manufacturing

The needs of your company will determine the kind of bottle washing machine you need. For example, a small research lab may only need a cabinet bottle washer to meet all of their sanitation requirements, while a brewery would require a fully automated glass bottle washer that can thoroughly clean hundreds of bottles per hour. Niagara Systems can build custom industrial bottle washers to cover all of our client’s needs.

Types of Bottle Washer Machines

For commercial bottle washers, there are a number of variants that companies use across different industries. Aside from custom high-pressure bottle washers, there are three main varieties available on the market — cabinet and carousel, and tunnel — and they come in two methods of operation: semi-automated and automated.

Bottle Washer Cabinet

A parts washer cabinet has a smaller footprint than the carousel style and is intended for low-production operations. A drawer is manually loaded and slid into the washer. A cabinet bottle washer is ideal for automotive parts washing and cleaning lab components, such as beakers and testing equipment.

Carousel Washer

A carousel or bottle washer is intended for medium to high-volume production lines. The carousel bottle washer is often integrated into larger assembly lines so bottles can be cleaned and dried in preparation for the next process. Carousel washers are capable of cleaning hundreds of bottles per hour to keep up with larger production rates. Utilizing multiple stages of full coverage sprays while washing and heated drying cycles to increase throughput and quality. Carousel bottle washers share a load and unload location, minimizing necessary operators or making robotic integration possible at a lower cost.

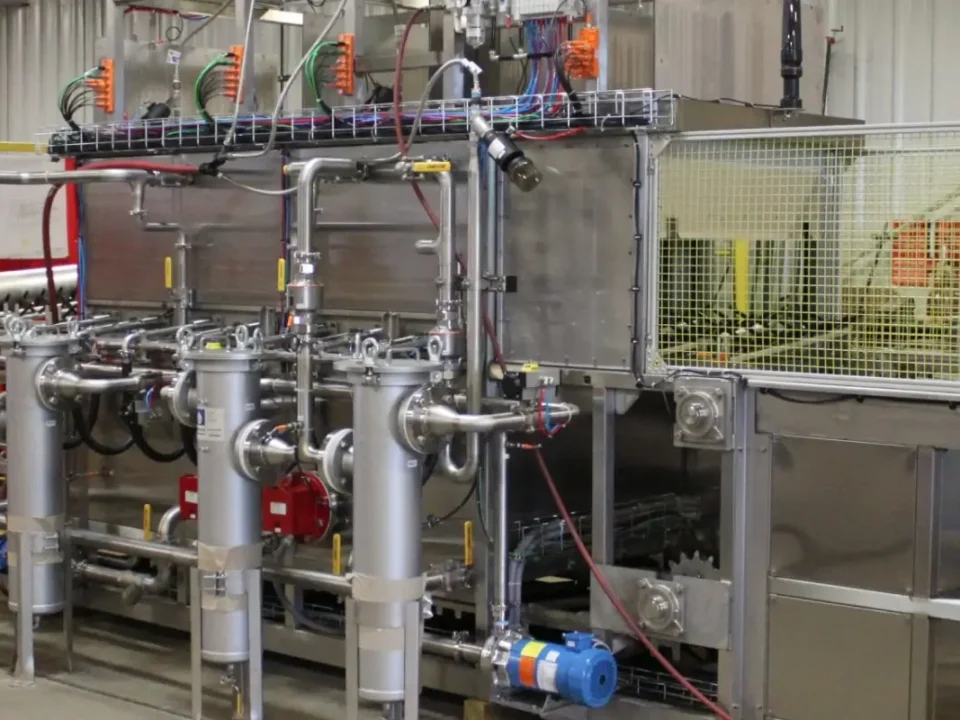

Tunnel Washer

A tunnel or conveyor parts washer is intended for high-volume production lines or single flow automation lines. The tunnel bottle washer is often integrated into a larger automation line so bottles can be cleaned or chemically treated and dried in preparation for the next manufacturing process. Tunnel washers are capable of cleaning thousands of bottles per hour to ensure the washing process is not the bottleneck of the manufacturing process. Utilizing multiple stages of full coverage sprays while washing with the correct pressures and heated drying cycles increase throughput and quality, tunnel bottle washers are ideal if volume is a major factor.

Semi-Automated

A semi-automated bottle washer system requires input from a user to begin its wash cycle. Manual loading and unloading is required, and the user will select the settings under which to run the washer. Semi-automated bottle washing machines are intended for low-volume runs. Most cabinet washers are semi-automated.

Automated

Automated bottle washers are mostly hands-off in that they run under prescribed settings to meet sanitation requirements. Loading and unloading can be accomplished by robotics, and the system will automatically adjust settings such as stream pressure and temperature. High-volume beer bottle washers are good examples of automated systems, allowing for independent control of the wash cycle.

Things to Consider When Buying a Bottle Washer Machine

There are several factors to consider when you are purchasing an industrial bottle washer. While there are other pertinent details to address, these are some of the basics that we ask our clients about when helping them buy or customize a high-pressure bottle washer.

1. Volume

How much capacity do you need? High-volume workflows will have vastly different requirements than small operations. For lab testing equipment, a cabinet bottle washer could suffice. For a large vineyard that needs a wine bottle washer, a carousel system would be required.

2. Footprint

The amount of space that you have available for your bottle washing machine will be a big factor. Fitting an automatic bottle cleaner into a smaller footprint can create bottlenecks and logistics issues that may be solved with a custom system.

3. Turnaround

How fast your bottle wash cycle needs to be in order to maintain the level of inventory for your application can affect different aspects of the wash cycle. The amount of time you have for the rinse and drying process may determine things like temperature control, water pressure and other factors to give you the best cleaning solution in the appropriate amount of time.

4. Flexibility

Single-purpose units can be highly customized to perform the one specific cleaning task that you require. Changes can be made to water pressure, temperature and other parameters to maximize cleaning efficiency. Multipurpose bottle washers are made to handle different cleaning applications that can handle unique washing situations where flexibility is as important as timeliness.

Contact Niagara Systems for a Custom Bottle Washer

Designing washing solutions has been the main focus of Niagara Systems for decades. Our bottle washing machines are the culmination of design and engineering excellence. Customers worldwide have harnessed the expertise of our team to get bottle washer solutions that work for them. Contact a representative today to discuss how Niagara Systems can build the best industrial bottle washer just for you.