- Keeping it clean since 1934!

- (440) 259-2500

- [email protected]

Relative Humidity vs. Temperature

November 4, 2021

Tunnel Washer Buying Guide

December 7, 2021

Conveyor Belt Washer Selection Guide

You have thousands of parts coming off the production line each day. There’s no room for bottlenecks or production slowdowns. Every part of the operation needs to run at peak efficiency. You need an industrial washing system that’s up to the task. A conveyor washer is often the answer to overcome these difficult challenges. Read on to learn about these industrial washers and how they can benefit your manufacturing operation and customer satisfaction.

What is a Conveyor Washer?

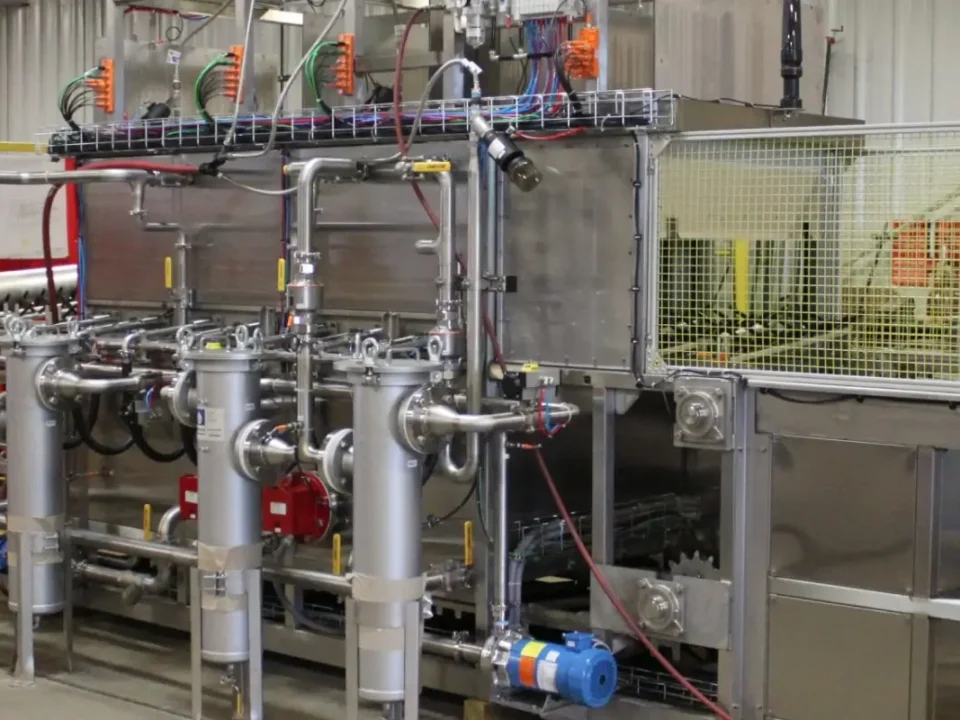

A conveyor washer is exactly what it sounds like: an industrial washer that moves parts through washing and drying stations via a conveyor. They enable the continuous cleaning of parts and are designed to efficiently remove oil, debris, dust and other residue from a wide range of products.

Carousel Washer Parts

No matter how complex it is or what the application might be, every carousel washer has the same components. Look at any conveyor belt washer, and you’ll find:

- Returning Conveyor System – the carousel design allows loading and unloading of parts to happen at the same location. This is ideal to minimize manpower to operate the industrial wash system as well as ease of integration to robotic loading and unloading.

- Wash Chamber — the stainless steel chamber that contains the washing process, including glass windows for easy inspection and visibility of the process.

- Heater — to heat the water or chemistry to the process specification

- Pumps — to deliver water and chemistry through the system and provide the proper flow, impact, and impingement of process chemistry to the parts to properly clean and/or treat the materials

- Filters — to remove particulate from the liquids as it recirculates through the system, providing both cost savings and ecological benefits

- Nozzles — to direct the spray ensuring full coverage of the parts.

- Dryers — a combination of air turbulence and heat specific to the parts

Operation of a Conveyor Washer

Whether it’s a carousel glass washer or a conveyor belt washer handling large automotive parts, most conveyor washing systems work in the same way. Although every conveyor washer can be customized to meet a customer’s specific needs, the process generally includes these steps:

- 1. Parts are placed in the washer at a loading station.

- 2. Parts enter a washing station where they’re sprayed with a cleaning solution to dislodge debris.

- 3. Parts enter a buffer station to minimize chemical carryover.

- 4. Parts are sprayed after moving to a rinsing station.

- 5. Parts move to another draining station.

- 6. Parts move to the drying station.

- 7. Parts are unloaded.

Conveyor Belt Washer Applications

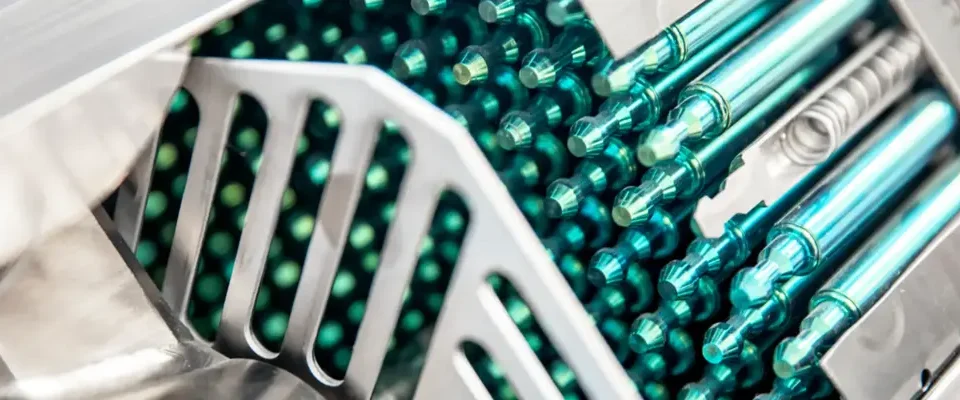

Conveyor washing systems are popular solutions in the laboratory, food processing and automotive parts manufacturing industries. Depending on their construction, they’re ideal for parts like:

- Pistons

- Crankshafts

- Ordinances

- Bottles

- Gaskets

- Cylinders

- Castings

- Machined parts

- Totes

- Dunnage

- Tubing

Carousel Washer Characteristics

Just as each conveyor belt washer has similar components, good carousel washers share similar characteristics. To successfully deliver the performance your operation requires, a carousel washer should offer:

- Flexibility — A washer with a reduced footprint can fit in nearly anywhere within your operation.

- Productivity — A design that minimizes washing and drying while meeting your cleanliness requirements will save you time and money.

- Sustainability — Reducing water and electricity usage is good for the planet — and your bottom line.

- Ease of use — Large observation windows and easy-to-program controls can ease cycle monitoring and operation.

- Durability — A made-in-the-USA industrial washer can provide years of dependable service.

- Safety — Look for redundant safety logic to keep operators safe.

How to Know You Need a Conveyor Belt Washer

As with any capital investment, the timing of your industrial washer installation is key. You want to make sure you’re ready to take advantage of the efficiencies provided by a conveyor parts washer. In evaluating your needs, you should consider these questions:

- Is your existing cleaning process causing production bottlenecks?

- Do you need to process a higher volume of parts than in the year(s) past?

- Is your process providing adequate cleaning expectations to your customer?

- Are you sending out parts to be washed by a third party?

- Is cleanliness or chemical processing imperative to the finished product you are providing?

- Are your cleaning processes highly manual and using too much of your labor resources?

If you answer “yes” to these questions, you’ll want to consider installing a conveyor belt washer.

How to Select a Conveyor Washer

Once you’ve decided that a conveyor belt washer is right for your application, you’ll want to find the best fit for your operation. Identifying a washer manufacturer with a proven track record of success is important, as is finding a vendor that will customize your industrial conveyor washer to meet your specific needs. When it comes to the washer itself, you’ll want to look for features like:

- Stainless steel construction

- Full insulation industrial washer, which decreases heat loss and improves efficiencies.

- Multi-stage filtration allowing recirculation of tanks and reduces operating costs

- A PLC-controlled HMI touch screen providing flexibility

- Remote service capabilities

- Ease of maintenance and machine access

- Proven processes

- Expected machine life

- A manufacturer that provides: process development, machine design, electrical panel design and build, machine manufacturing, installation services, and field service support.

You’ll also want to look for important optional capabilities to further automate your equipment. Whether it is robotic loading/unloading, belt transfers, zero downtime maintenance or any other type of upfront or future automation – ensure your selected conveyor washer vendor can support your automation or integration needs.

Niagara Systems Has the Conveyor Belt Washer You Need

As a leading carousel washer manufacturer, we have 85+ years of experience designing and creating the industrial washer that meets each customer’s specifications. Manufacturers around the world rely on our conveyor washing systems to clean their parts of oil and other debris. Contact us today to learn how a Niagara Systems conveyor belt washer can meet your requirements.