Niagara Systems has been providing industrial and commercial bottle washer solutions since 1934 — and we aren't stopping anytime soon. Our bottle washers have been used across a wide range of industries for varied applications, boasting an impressive range of features for proven results, including:

- Wash 200 to 750+ Bottles Per Hour

- PLC-controlled & Programmable Touch Screen

- Self-Diagnostics For Real-Time Monitoring

- Superior Drying & Filtering System

- Fully Insulated

Niagara Systems continues to innovate, ensuring that our commercial bottle washers remain a top choice for varied applications across multiple industries. Request a quote today!

Get a Quote »What Industry Specifications Do Niagara Systems Bottle Washers Meet?

We’ve created high-production bottle cleaning machines for the beverage and food industry, semi-automatic machines for large pharmaceutical laboratories, small-production industrial bottle washer solutions for oil refinery labs requiring high outputs and many more. No matter what type of operation you have, Niagara Systems can design and build an effective, reliable bottle washing machine that will last for decades.

Our commercial bottle washers must be made to the proper specifications to meet the stringent demands and versatility of all the industries we serve. As such, our bottle cleaning machines are designed to comply with the following:

- Food-Grade Specifications: Our bottle washers meet stringent cleanliness and safety standards required in the food and beverage industry, ensuring impeccable hygiene.

- Pharmaceutical Industry Specifications: Designed for precision and contamination control, Niagara System’s bottle cleaning machines are ideal for the rigorous demands of pharmaceutical environments.

- Electronics Industry Specifications: Tailored for the electronics sector, our bottle washers handle delicate components with the utmost care and precision.

- And Many More

Additionally, we can design a custom bottle washer and dryer to suit your specific needs, and we’ll work with you to get it done right.

Industrial & Commercial Bottle Washer Applications

There is no shortage of bottles, containers and other applications that our industrial and commercial bottle washer solutions can handle. Here are some of the most common examples that exhibit the wide range of opportunities available:

- Refinery Laboratory Bottles and Glassware: Ideal for the rigorous cleaning required in oil and chemical labs.

- Pharmaceutical Laboratory Bottles and Glassware: Precision cleaning to meet stringent health and safety standards.

- Pressurized Aluminum Bottles: Capable of handling the unique challenges posed by pressurized containers.

- Recyclable Glass Bottles: Efficient cleaning solutions for eco-friendly glass recycling processes.

- Electronics & Containers: Tailored to clean sensitive electronic components and containers safely.

- Plastic Bottles: Versatile enough to clean various types of plastic containers effectively.

- Beer Bottles and Glassware for Microbrewers: Custom solutions for the specific needs of craft brewing operations.

- Wine Bottles and Glassware for Wineries: Specialized cleaning for the delicate requirements of the wine industry.

Niagara Systems is happy to work with you to determine what kind of bottle cleaning machine would work best for your application to ensure product safety.

Which Bottle Cleaning Machine Design Is Right for Your Operation?

Our industrial bottle washers are all designed to be suitable for a wide range of applications. Deciding which of our bottle cleaning machines is best for you largely depends on the production output your operation requires. That said, most customers find that the bottle washer cabinet design is the optimal choice for cleaning bottles.

Bottle Washer Cabinet

A parts washing cabinet works exceptionally well for low-production operations of 200 bottles or less per hour. This tends to be the best option for those who need high pressure bottle washing and cleaning machines.

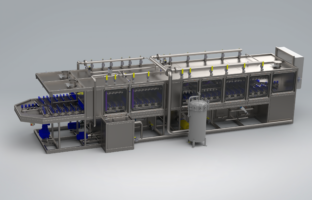

Carousel Conveyor Bottle Washing Machine

Our carousel bottle washing machines are suitable for medium production of 200 to 750 bottles per hour. They are particularly well-suited for industries that require medium to high-volume washing applications, such as food processing, pharmaceuticals and laboratories.

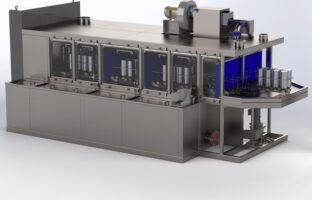

How to Install a Bottle Washer

Installing a bottle washer from Niagara Systems involves several considerations and steps that depend on the specific model and the needs of your operation. Niagara Systems offers a variety of bottle cleaning machines, including cabinet, carousel and tunnel washers, each designed for different production volumes and applications.

- Installation Space: Ensure you have adequate space for the bottle washer. The space required will depend on the model you select. For example, cabinet washers have a smaller footprint compared to tunnel washers.

- Integration into Production Line: If you’re integrating the bottle washer into a production line, consider how it will fit your existing processes. Niagara Systems offers solutions that can be integrated into production lines, especially in industries like beverage manufacturing.

- Customization Options: Niagara Systems can customize bottle washers depending on your specific requirements. This includes adjustments to water pressure, temperature and other parameters to maximize cleaning efficiency.

- Installation Process: The actual installation process will vary depending on the type of washer and your facility’s setup. It may involve setting up the machine, connecting it to power and water sources, and configuring its settings.

- Training and Operation: Once installed, staff training is crucial to ensure the safe and efficient operation of the machine. Familiarize your team with the washer’s functions, maintenance requirements, and safety protocols.

For more detailed installation instructions, it’s best to contact us directly or refer to the specific user manual for your chosen model. Since the installation can be complex and varies greatly based on the type of washer and your specific needs, professional guidance from Niagara Systems will ensure that your bottle washing machine is installed correctly and operates optimally.

Get the Bottle Washer You Need at Niagara Systems

With our industry experience, there’s no question that our bottle washer and dryer machines will work for you — and last for a long time. Request a quote today to get started. We’ve proven our commitment to quality, and we’re committed to helping our customers, too, no matter where they are in the world.

If you have any questions about our bottle washers, don’t hesitate to contact us today.

General Questions For Commercial Bottle Washing Machines

If you have any questions or want to learn more about our commercial bottle washing machines, check out the answers to our most frequently asked questions below.

What Is a Bottle Washer?

A bottle washer is a specialized machine designed for cleaning and sterilizing bottles in commercial and industrial settings. By efficiently removing residues and contaminants from bottles, washers ensure they are hygienic for reuse or filling. They often integrate advanced technology for precise cleaning and can handle high volumes of bottles.

How Long Is a Bottle Washer Cycle?

The duration of a bottle washer cycle varies depending on the specific machine and its settings. Cycles include several steps, such as filling with water and soap, washing, draining and rinsing. However, it’s important to note that these times can be customized to suit specific washing, sanitizing, or rinsing needs.

What Is an Automatic Bottle Washer?

An automatic bottle washer has a built-in cleaning system that automatically washes bottles. Bottles are cleaned by rinsing and removing loose particulates with high or low-pressure nozzles. The system can be customized with a water filtration system to recycle the water pumped back into the machine’s tanks.

Can a Commercial Bottle Washer Be Integrated Into a Production Line?

Yes! Commercial bottle washers can be easily integrated into a production line. Niagara Systems works with manufacturers to integrate commercial bottle washers into production lines to keep product bottles clean. Our washing systems are commonly used in the beverage industry and can be fully automatic or semi-automatic when integrated. Bottle washers can wash hundreds of bottles per hour and even clean the outside of bottles, minimizing the need for operators to use water efficiently.