Using reusable storage systems, such as returnable plastic containers, dunnage, and delivery packaging, is an excellent way for modern industries to cut costs and reduce environmental impact. However, reusable containers can become a liability without proper cleaning, leading to cross-contamination and product damage. That's where Niagara Systems comes in. Our returnable plastic container cleaning systems can handle your toughest contaminants.

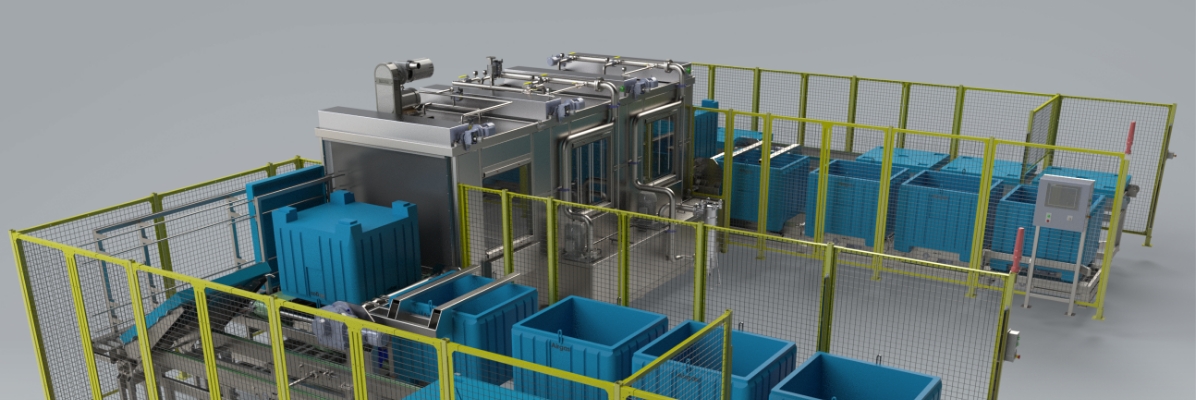

Looking for a custom solution? Choose Niagara Systems. Our team specializes in creating custom returnable plastic container cleaning systems tailored for niche industries with highly specific needs. Whether you're working with heavy soils or need sanitary solutions, we can build a custom system that meets your cleaning standards, improves your workflow efficiency, and extends the life of your containers. Interested? Tell us about your project and request a quote today!

Get a Quote »Industry-Specific Applications of Returnable Plastic Container Cleaning Systems

Returnable plastic container cleaning systems are versatile solutions that can benefit many industries by keeping reusable containers clean, sanitary, and in optimal condition for continuous use.

Automotive Industry

In the automotive industry, precision is everything. Parts like engines, transmissions, and brake components are often transported using returnable dunnage to ensure safe handling. Dirty or contaminated dunnage can introduce oils, greases, or debris into sensitive areas, compromising quality control.

Niagara Systems offers returnable dunnage cleaning systems that remove these contaminants with high-pressure washing and automated drying, ensuring parts stay protected and production stays on track.

Food Processing Industry

In food processing, safety and sanitation are top priorities. Returnable plastic container cleaning ensures that reusable crates, trays, and bins are free of residues, allergens, or bacteria.

By incorporating custom high-temperature wash cycles, Niagara’s systems can help food producers meet stringent regulatory standards, while preventing contamination during product transport. These solutions are ideal for delivery packaging cleaning where cleanliness is critical to maintaining product quality.

Pharmaceutical and Medical Industries

Precision cleanliness is critical in pharmaceuticals, where even trace contaminants can cause serious issues. For the pharmaceutical and medical industries, returnable storage cleaning must meet stringent sanitation standards.

Niagara Systems’ specialized solutions can be custom-fitted with advanced filtration systems and sanitizing agents to ensure medical trays, bottles, or drug transport containers are sterile after every cycle. This keeps production lines compliant with health standards and reduces waste from single-use alternatives.

Manufacturing and Distribution

Manufacturing facilities and distribution centers rely on reusable storage cleaning systems to keep their material handling processes smooth and efficient. Dirty containers can lead to damaged goods, worker safety issues, and costly downtime.

Niagara’s cleaning systems are built to handle high volumes of returnable storage cleaning with minimal manual intervention, ensuring that containers are cleaned thoroughly and ready for the next cycle.

Key Features of Niagara Systems’ Washers

Niagara Systems’ returnable plastic container cleaning systems are designed with cutting-edge features that address the unique needs of various industries. Whether cleaning heavy-duty automotive dunnage or sanitizing food-grade crates, Niagara’s washers provide unmatched performance and reliability.

Here’s a breakdown of some of the key features that set Niagara apart:

- Customizable Cleaning Configurations: Adjust water pressure, temperature, and chemical use for precise delivery packaging cleaning and returnable dunnage cleaning, tailored to each industry’s requirements.

- High-Pressure Washing: Effectively removes oils, grease, and grime, ideal for industries like automotive and manufacturing.

- Integrated Drying: Fast, efficient drying systems ensure containers are ready for immediate reuse, preventing downtime.

- Modular Design: Flexible setups fit into any production line, making the systems adaptable for high-volume cleaning needs.

- Energy-Efficient Operation: Smart controls reduce water and energy consumption, helping businesses meet sustainability goals.

- Advanced Filtration and Sanitization: Chemical dosing, UV sanitization, and HEPA filtration ensure containers meet stringent hygiene standards, critical for food processing and pharmaceuticals.

- Automated Controls: Real-time monitoring and automated features reduce manual intervention, improving workflow and efficiency.

Niagara Systems builds washers with the precision, durability, and scalability to meet the highest industrial demands. With these advanced features, businesses can rely on Niagara for returnable plastic container cleaning solutions that save time, reduce costs, and keep their processes running smoothly.

Find the Configuration to Meet Your Needs

At Niagara Systems, we understand that every industry has unique returnable plastic container cleaning requirements. That’s why we offer an extensive selection of washers in various configurations to suit any operational need. From compact cabinet-style washers ideal for smaller batch cleaning to continuous conveyor systems for high-volume returnable storage cleaning, we build systems that integrate into your workflow.

Series 200 Model MT23: Built for High-Performance Returnable Plastic Container Cleaning

When high- to medium-volume returnable plastic container cleaning is a daily operational demand, the Series 200 Model MT23 from Niagara Systems delivers the performance you need. Equipped with adjustable belt speed, it easily handles various container sizes, ensuring optimal cleaning across various parts. The 304 or 316 stainless-steel construction guarantees durability, while its wash-down componentry and food-grade construction make it ideal for industries with strict hygiene standards, such as food processing and pharmaceuticals.

Whether working with delivery packaging, returnable dunnage, or reusable storage cleaning, this model easily integrates into existing automation systems and offers flexible controls for complete customization.

Invest in the Future of Your Operations with Niagara Systems

Cutting corners isn’t an option when it comes to maintaining the efficiency and reliability of your production line. Niagara Systems’ returnable plastic container cleaning systems are built for industries that demand durable, long-lasting equipment. With solutions that minimize downtime, reduce energy consumption, and offer precise, thorough cleaning, our systems can handle the toughest environments while conserving your resources.

Equip your operation with a solution that meets today’s standards and is ready to exceed tomorrow’s challenges. Contact Niagara Systems to find out how our systems can transform your workflow and protect your investment for years to come.

Frequently Asked Questions: Reusable Storage Cleaning

If you have questions or want more information about our reusable storage cleaning solutions, check out the answers to our most commonly asked questions for more insights.

What types of contaminants are typically targeted in reusable storage cleaning?

Common contaminants include oils, dirt, grease, chemicals, and biological debris such as food particles or bacteria. Effective cleaning systems like those from Niagara Systems are designed to remove these with a combination of high-pressure washing, chemical treatments, and filtration to ensure full sanitation.

Can reusable storage cleaning systems handle multiple container sizes?

Yes, many cleaning systems are designed to be flexible and adjustable, allowing them to accommodate different container sizes without compromising the cleaning process. Niagara Systems offers solutions with adjustable belt speeds and customizable configurations to handle various storage types.

What is the role of automation in reusable storage cleaning systems?

Automation in reusable storage cleaning minimizes manual labor, improves consistency, and increases efficiency. Automated loading, washing, and drying ensure faster turnaround times, reduce the risk of human error, and allow systems to operate continuously with little to no downtime.