If you need an electronic parts cleaner, look to the experts at Niagara Systems. Our electronics and semiconductor cleaning machines utilize high-frequency sound waves to create cavitation bubbles that effectively strip away contaminants like flux, oils, and dust from the smallest crevices in electronic components. Whether you're cleaning microchips, circuit boards, or other sensitive components, our solutions provide deep, thorough cleaning without the risk of damage.

Need a customized solution? We excel at building custom electronic cleaning equipment that fits the specific needs of your operation. From specialized cleaning for high-sensitivity semiconductor wafers to unique builds for niche applications like medical electronics, we can design and engineer a custom electronics cleaner to meet even the most demanding requirements. Let's talk about your specifications! Request a free quote today.

Get a Quote »Our Specs Suit Your Industry-Specific Applications

Niagara Systems’ semiconductor cleaning machines and electronics cleaning equipment thrive in industries where precise, contaminant-free components are critical. Businesses in the medical, aerospace, and consumer sectors all require clean, defect-free parts to maintain the performance and reliability of their products.

Check out a few examples of how key industries like these benefit from high-quality ultrasonic cleaning equipment.

Semiconductor Manufacturing

Semiconductor fabs require the highest levels of cleanliness, as microscopic contaminants can lead to defective wafers and reduced chip performance.

Our semiconductor parts cleaning systems effectively remove residues, such as photoresist, metal particles, and polishing compounds from production processes. This level of precision cleaning ensures that each wafer is ready for the next stage of production, reducing waste and increasing yield.

Medical Device Manufacturing

The medical electronics industry demands an exceptionally high level of cleanliness to ensure that devices such as pacemakers, diagnostic tools, and imaging systems function without failure. We design wash systems to meet the stringent requirements of medical applications, removing bioburden and manufacturing residues that could compromise device safety or performance.

Automotive Electronics

With the growing integration of electronic systems in vehicles, ensuring the cleanliness of sensors, control units, and wiring is vital to the reliability of modern cars. Electronics parts cleaners eliminate oils, particulate matter, and machining residues from automotive electronic components, ensuring they meet performance and safety standards in harsh environments.

Aerospace Electronics

Precision is critical in aerospace applications where electronic systems must function flawlessly in extreme conditions. Our equipment ensures that sensors, avionics, and control systems are free from contaminants that could cause malfunctions or short circuits.

Consumer Electronics

For manufacturers of smartphones, computers, and other consumer devices, cleanliness impacts not only performance but also the aesthetic quality of the final product.

Our electronics cleaning machines can be customized to clean components such as circuit boards and connectors, removing flux and solder residues to prevent corrosion and improve long-term reliability.

![]()

Superior Cleaning Solutions for Every Component

Niagara Systems designs electronics cleaning machines and semiconductor parts cleaning systems with advanced features that enhance performance and reliability. Here are some of the standout features:

- Precision Ultrasonic Cavitation: Our machines utilize high-frequency ultrasonic waves to generate millions of microscopic bubbles, providing deep cleaning even in the tiniest crevices of complex components. This non-abrasive method ensures effective contaminant removal without damaging delicate parts.

- Temperature Control: Consistent, adjustable heating ensures the cleaning solution maintains the optimal temperature for breaking down oils, flux, and residues during electronics cleaning. This feature is particularly beneficial for sensitive semiconductor parts that require exact cleaning conditions.

- Automated Process Control: Integrated with cutting-edge automation technology, our systems offer precise control over the cleaning cycle, from solution agitation to rinse and dry stages. This level of automation improves cleaning efficiency and ensures repeatability across batches, a critical factor for industries requiring consistent output.

- Customizable Cleaning Parameters: Each system can be tailored to handle specific contaminants and part geometries, offering customizable cleaning cycles, solution chemistry compatibility, and rinse options to match industry-specific needs.

Which Electronics Parts Cleaner Is Right for You?

Niagara Systems offers a great selection of electronics parts cleaners in multiple configurations to suit any production environment. Whether you need a compact unit for cleaning delicate circuit boards or an industrial-scale system for large semiconductor components, our washers offer flexible, scalable solutions to match your demands.

Sonixclean SC-16

For businesses looking for a mid-sized solution, the Sonixclean SC-16 is the answer. It features a 16-gallon capacity and works great for cleaning smaller batches of electronics without sacrificing power. Its 800Wp ultrasonic generator (1600 Wp-p) paired with 16 high-performance PZT transducers ensures deep, thorough cleaning, using the power of 40 KHz ultrasonic waves to eliminate contaminants like oils and dust.

The heating element (3x450W) maintains the ideal temperature for cleaning delicate electronic components, ensuring they emerge completely clean and ready for the next step.

Talk to Us About Your Project Today

When precision and performance matter, the right cleaning equipment can be the difference between success and costly downtime. Niagara Systems delivers the reliability and customization you need for semiconductor and electronics parts cleaning.

With decades of expertise, we build solutions that match your exact requirements. Let Niagara Systems equip your operation with the tools needed to stay ahead in your industry.

![]()

Frequently Asked Questions: Electronic Cleaning Equipment

If you have any questions or would like to learn more about electronic cleaning equipment, take a look below for the answers to our most commonly asked questions.

Can ultrasonic cleaning damage electronic components?

When used correctly, ultrasonic cleaning is safe for electronic parts. The key is selecting the right frequency and cleaning solution. Higher frequencies (such as 40 kHz) are recommended for sensitive electronics as they produce gentler cavitation, minimizing any risk of damage to delicate components like capacitors, sensors, or chips.

What precautions should be taken when cleaning electronic parts?

It is important to ensure that the cleaning solution used in electronics cleaning equipment is non-conductive and that all parts are completely dry after cleaning. If moisture is left inside electronic components, it can cause short circuits.

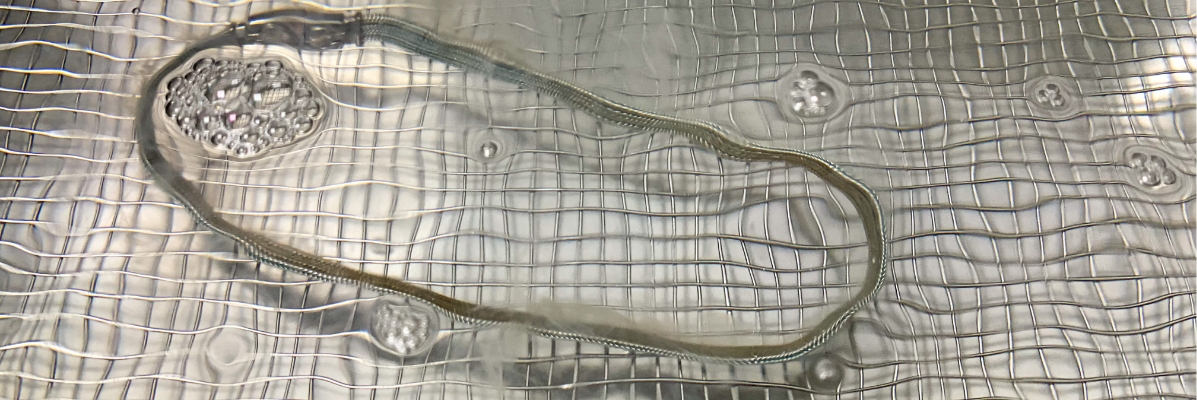

Can semiconductor wafers be cleaned using ultrasonic systems?

Yes, ultrasonic systems are ideal for cleaning semiconductor wafers. The precision offered by the cavitation bubbles ensures contaminants like photoresist, slurry residues, and particles from chemical-mechanical planarization (CMP) are effectively removed without scratching or damaging the wafer surface.